5.11

3507, 3508, 3509, 3512, 3513, 4007, 4008, 4009, 4012, 4013

Axles, Drive Shafts, Wheels and Tires

5.5.2 Installing Wheel and Tire Assembly

onto Machine

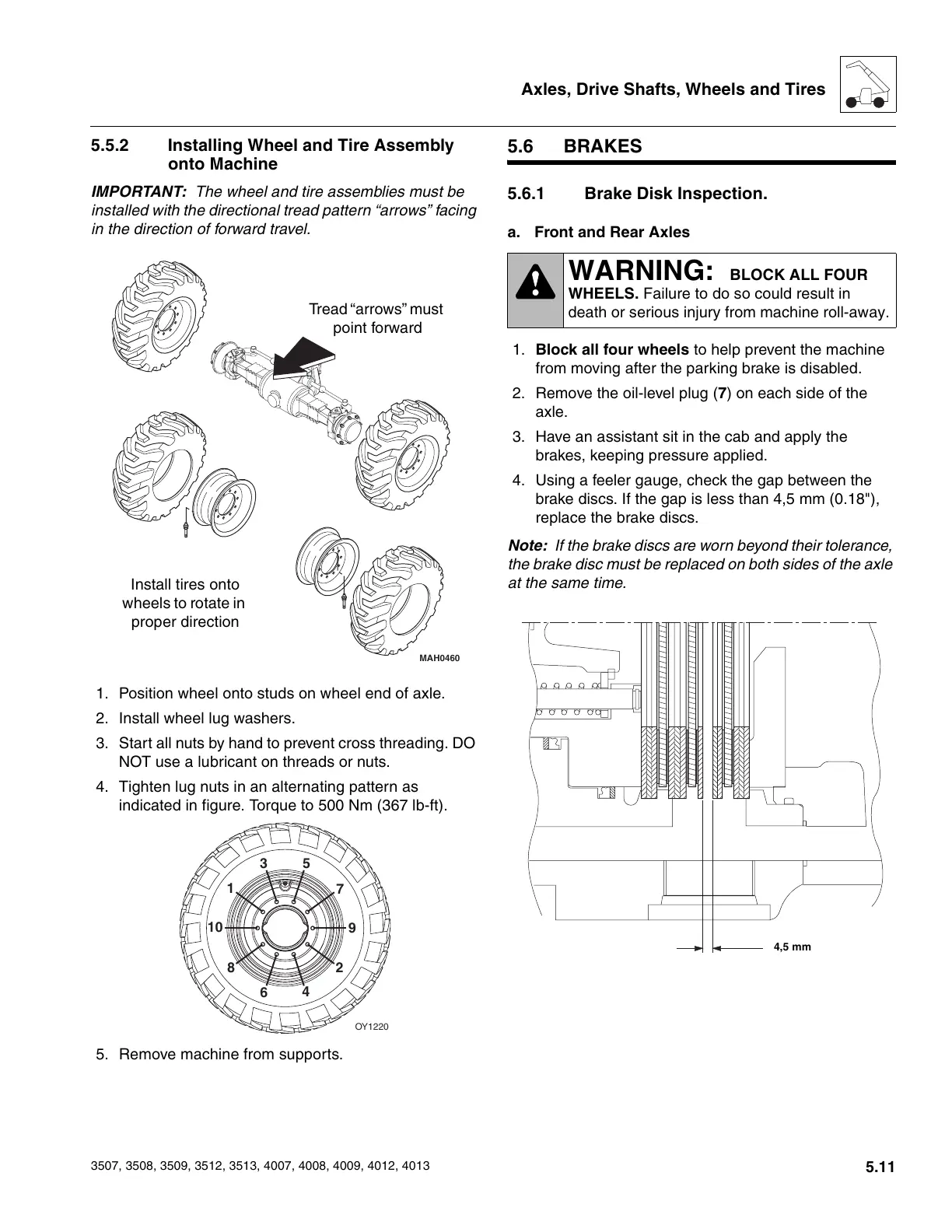

IMPORTANT: The wheel and tire assemblies must be

installed with the directional tread pattern “arrows” facing

in the direction of forward travel.

1. Position wheel onto studs on wheel end of axle.

2. Install wheel lug washers.

3. Start all nuts by hand to prevent cross threading. DO

NOT use a lubricant on threads or nuts.

4. Tighten lug nuts in an alternating pattern as

indicated in figure. Torque to 500 Nm (367 lb-ft).

5. Remove machine from supports.

5.6 BRAKES

5.6.1 Brake Disk Inspection.

a. Front and Rear Axles

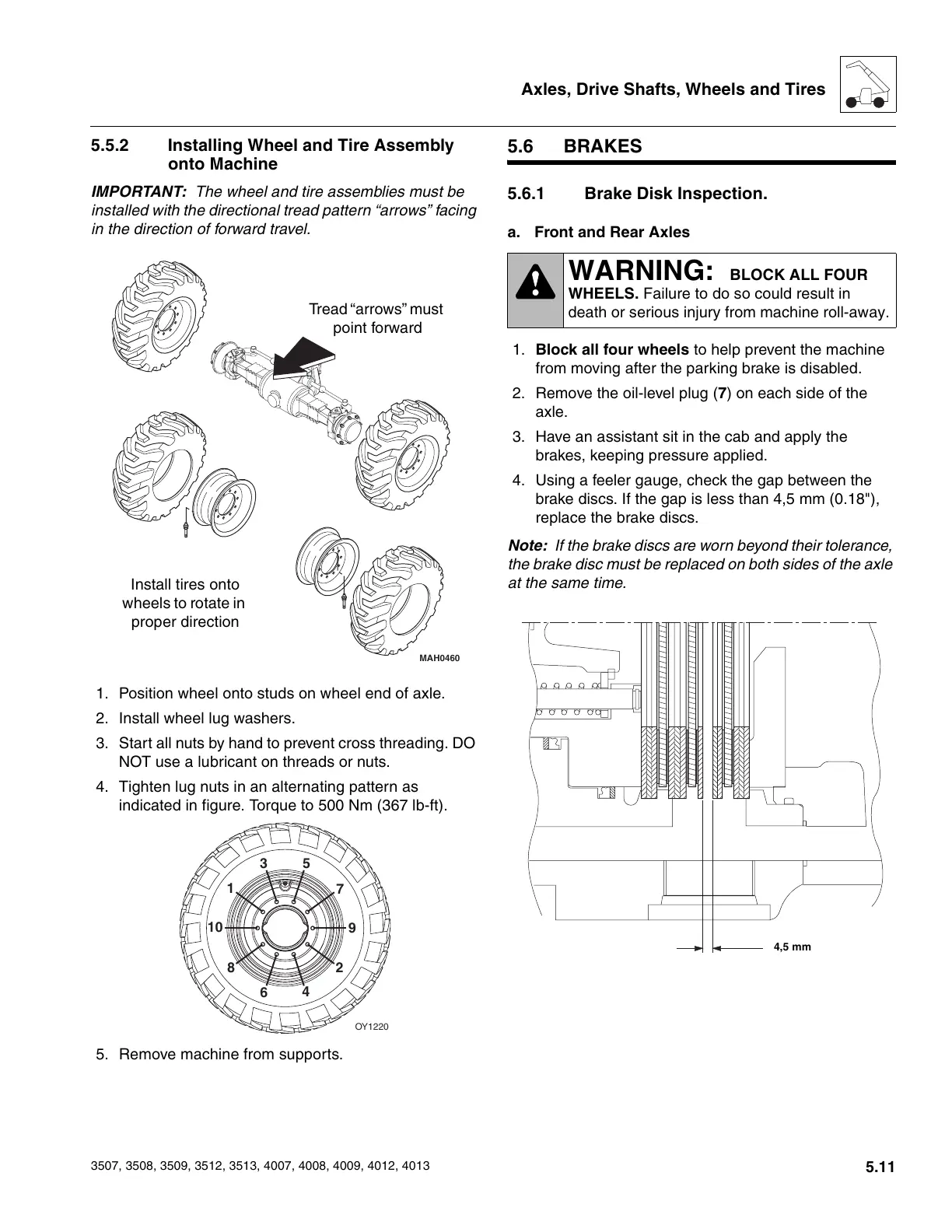

1. Block all four wheels to help prevent the machine

from moving after the parking brake is disabled.

2. Remove the oil-level plug (7) on each side of the

axle.

3. Have an assistant sit in the cab and apply the

brakes, keeping pressure applied.

4. Using a feeler gauge, check the gap between the

brake discs. If the gap is less than 4,5 mm (0.18"),

replace the brake discs.

Note: If the brake discs are worn beyond their tolerance,

the brake disc must be replaced on both sides of the axle

at the same time.

MAH0460

Tread “arrows” must

point forward

Install tires onto

wheels to rotate in

proper direction

OY1220

1

2

3

4

5

6

7

8

9

10

WARNING: BLOCK ALL FOUR

WHEELS. Failure to do so could result in

death or serious injury from machine roll-away.

4,5 mm

Courtesy of Crane.Market

Loading...

Loading...