Hydraulic System

8.18

3507, 3508, 3509, 3512, 3513, 4007, 4008, 4009, 4012, 4013

8.9.3 Cylinder Cleaning Instructions

1. Discard all seals, back-up rings and o-rings. Replace

with new items from complete seal kits to help

ensure proper cylinder function.

2. Clean all metal parts with an approved cleaning

solvent such as trichlorethylene. Carefully clean

cavities, grooves, threads, etc.

Note: If a white powdery residue is present on threads

and parts, it can be removed. Clean the residue away

with a soft brass wire brush prior to reassembly, and

wipe with loctite cleaner before reinstallation.

8.9.4 Cylinder Inspection

1. Inspect internal surfaces and all parts for wear,

damage, etc. If the inner surface of the tube does not

display a smooth finish, or is scored or damaged in

any way, replace the tube.

2. Remove light scratches on the piston, rod or inner

surface of the tube with a 400-600 grit emery cloth.

Use the emery cloth in a rotary motion to polish out

and blend the scratch(es) into the surrounding

surface.

3. Check the piston rod assembly for run-out. If the rod

is bent, it must be replaced.

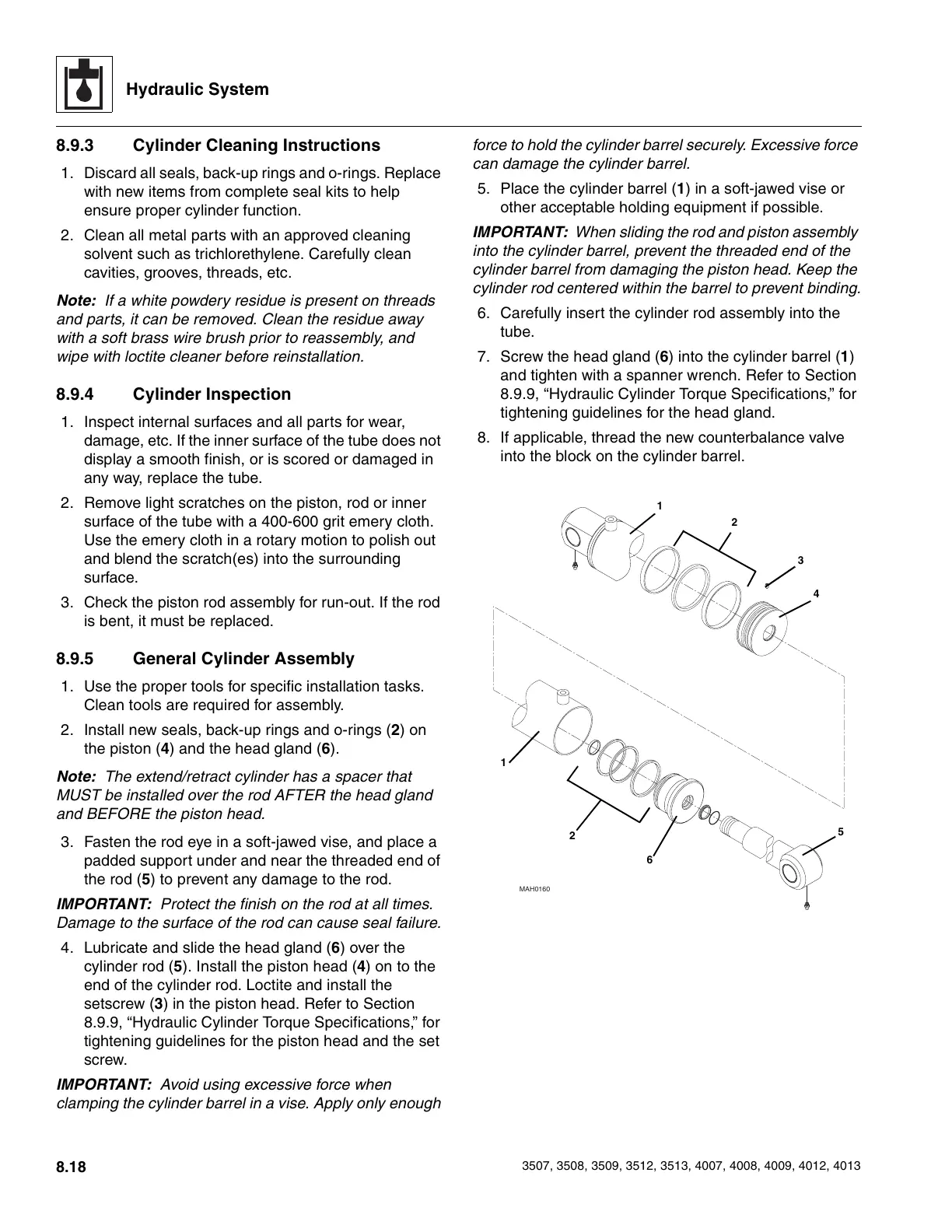

8.9.5 General Cylinder Assembly

1. Use the proper tools for specific installation tasks.

Clean tools are required for assembly.

2. Install new seals, back-up rings and o-rings (2) on

the piston (4) and the head gland (6).

Note: The extend/retract cylinder has a spacer that

MUST be installed over the rod AFTER the head gland

and BEFORE the piston head.

3. Fasten the rod eye in a soft-jawed vise, and place a

padded support under and near the threaded end of

the rod (5) to prevent any damage to the rod.

IMPORTANT: Protect the finish on the rod at all times.

Damage to the surface of the rod can cause seal failure.

4. Lubricate and slide the head gland (6) over the

cylinder rod (5). Install the piston head (4) on to the

end of the cylinder rod. Loctite and install the

setscrew (3) in the piston head. Refer to Section

8.9.9, “Hydraulic Cylinder Torque Specifications,” for

tightening guidelines for the piston head and the set

screw.

IMPORTANT: Avoid using excessive force when

clamping the cylinder barrel in a vise. Apply only enough

force to hold the cylinder barrel securely. Excessive force

can damage the cylinder barrel.

5. Place the cylinder barrel (1) in a soft-jawed vise or

other acceptable holding equipment if possible.

IMPORTANT: When sliding the rod and piston assembly

into the cylinder barrel, prevent the threaded end of the

cylinder barrel from damaging the piston head. Keep the

cylinder rod centered within the barrel to prevent binding.

6. Carefully insert the cylinder rod assembly into the

tube.

7. Screw the head gland (6) into the cylinder barrel (1)

and tighten with a spanner wrench. Refer to Section

8.9.9, “Hydraulic Cylinder Torque Specifications,” for

tightening guidelines for the head gland.

8. If applicable, thread the new counterbalance valve

into the block on the cylinder barrel.

MAH0160

1

4

3

2

6

5

2

1

Courtesy of Crane.Market

Loading...

Loading...