Engine: Perkins 1104-42 & 1104-42T

7.8

3507, 3508, 3509, 3512, 3513, 4007, 4008, 4009, 4012, 4013

d. Assembly

The fuel level indicator can be removed and reused on

the new replacement tank. Dispose of the old tank

according to local regulations concerning hazardous

materials disposal.

e. Inspection

Note: If a leak is suspected in the fuel tank, contact your

local JLG distributor.

1. Inspect the fuel tank thoroughly for any cracks,

slices, leaks or other damage.

2. Plug all openings except one elbow fitting. Install the

elbow fitting, and apply approximately 7-10 kPa

(1-1.5 psi) of air pressure through the elbow. Check

the tank for leaks by applying a soap solution to the

exterior and look for bubbles to appear at the

cracked or damaged area.

f. Fuel Tank Installation

1. Set fuel tank between frame rails.

2. Install the fuel tank strap over the fuel tank.

3. Install the fuel sender with new gasket into the fuel

tank and secure with screws. Tighten to 5 Nm

(3.6 lb-ft). DO NOT overtighten.

4. Connect the fuel supply hose and return line hose to

the tank. Secure with clamps and tighten to 25 Nm

(18 lb-ft)

5. Install the wire harness connections to the fuel

sender.

6. Fill the fuel tank according to specifications. Refer to

Section 2.4, “Fluids, Lubricants and Capacities.”

7. Check fuel tank for leaks.

8. Install the boom. Refer to Section 3.3.6, “Boom

Installation.”

9. Connect the battery negative (-) cable to the battery

negative (-) terminal.

10. Close and secure the engine cover.

7.6.3 After Fuel System Service

1. Drain and flush the fuel tank if it was contaminated.

2. Vent air from the fuel system in accordance with the

instructions found in the appropriate Operation &

Safety Manual.

3. Fill the fuel tank with fresh, clean diesel fuel as required.

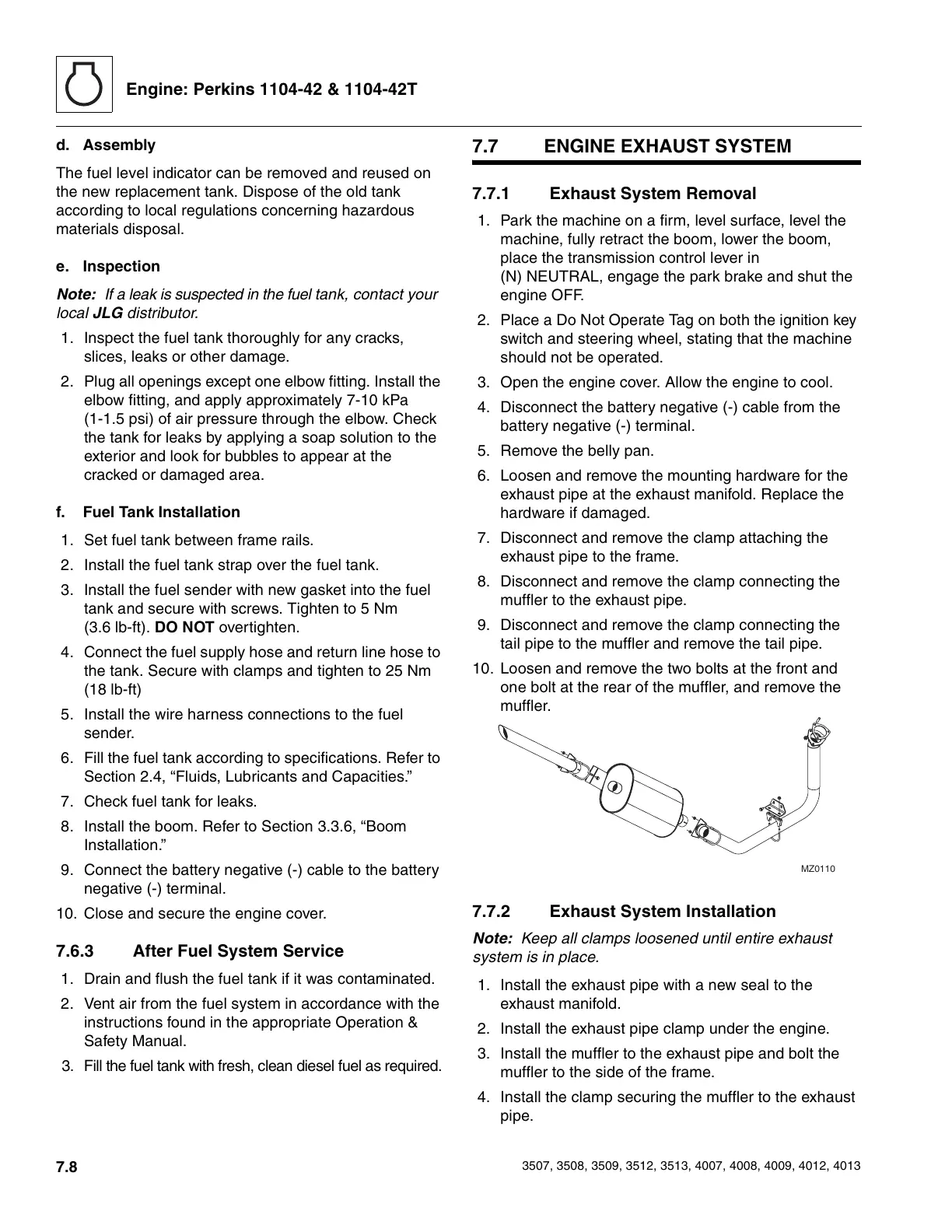

7.7 ENGINE EXHAUST SYSTEM

7.7.1 Exhaust System Removal

1. Park the machine on a firm, level surface, level the

machine, fully retract the boom, lower the boom,

place the transmission control lever in

(N) NEUTRAL, engage the park brake and shut the

engine OFF.

2. Place a Do Not Operate Tag on both the ignition key

switch and steering wheel, stating that the machine

should not be operated.

3. Open the engine cover. Allow the engine to cool.

4. Disconnect the battery negative (-) cable from the

battery negative (-) terminal.

5. Remove the belly pan.

6. Loosen and remove the mounting hardware for the

exhaust pipe at the exhaust manifold. Replace the

hardware if damaged.

7. Disconnect and remove the clamp attaching the

exhaust pipe to the frame.

8. Disconnect and remove the clamp connecting the

muffler to the exhaust pipe.

9. Disconnect and remove the clamp connecting the

tail pipe to the muffler and remove the tail pipe.

10. Loosen and remove the two bolts at the front and

one bolt at the rear of the muffler, and remove the

muffler.

7.7.2 Exhaust System Installation

Note: Keep all clamps loosened until entire exhaust

system is in place.

1. Install the exhaust pipe with a new seal to the

exhaust manifold.

2. Install the exhaust pipe clamp under the engine.

3. Install the muffler to the exhaust pipe and bolt the

muffler to the side of the frame.

4. Install the clamp securing the muffler to the exhaust

pipe.

MZ0110

Courtesy of Crane.Market

Loading...

Loading...