94

Maintenance

Operator’s Manual QUADRIGA 1000/BB

6.0-3

6.0-2

6.0-1

T

G

S

F

R

9

12

2

10

11

14

13

15

Every week,

carry out:

• Wash with cold water and soap or non-aggressive

chemical detergents.

• Dust only the bead breaking disks and tool guards

with talc.

on the parts:

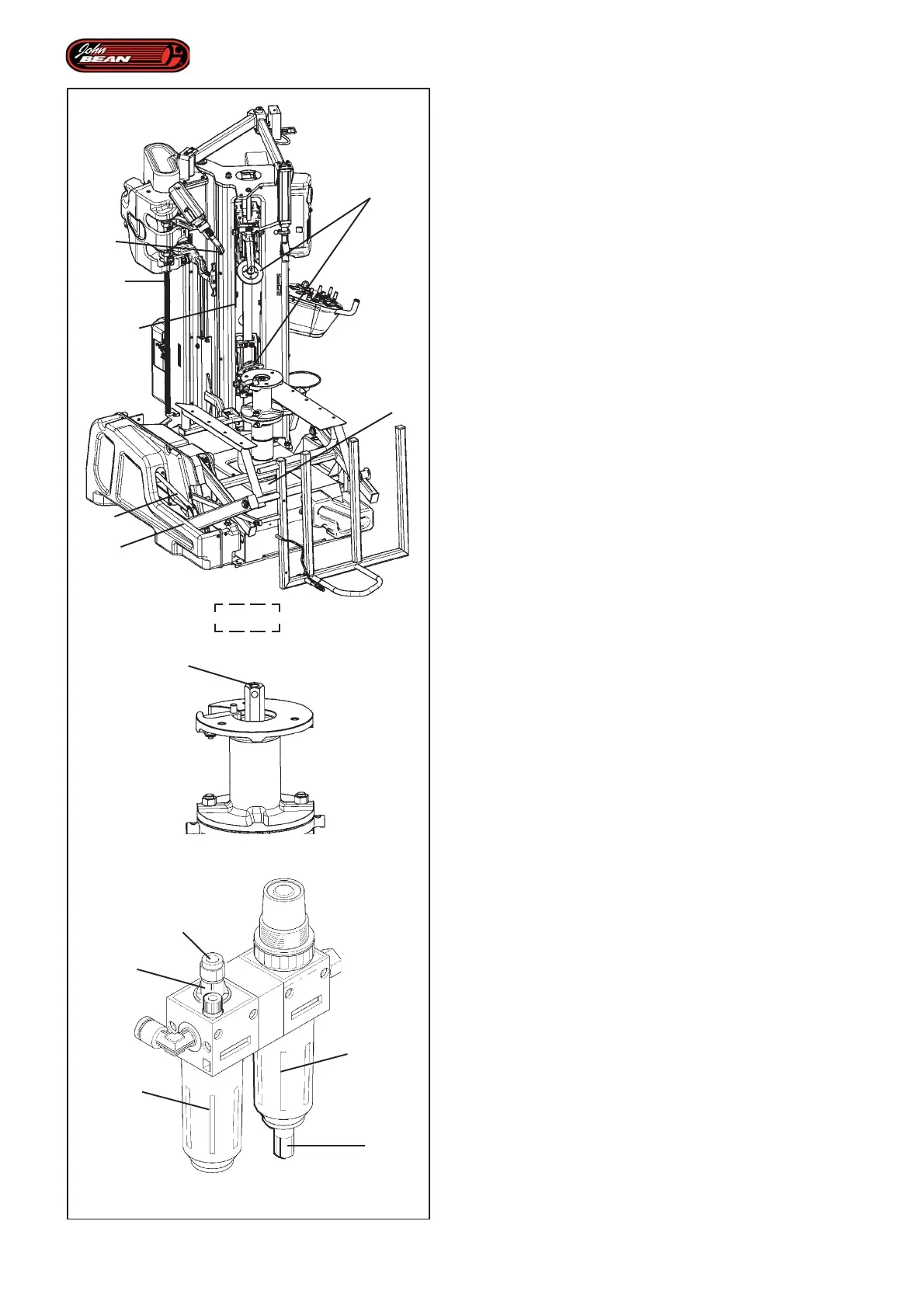

Figure 6.0-1

9) Plastic guards for lifter parts

10) Plastic guards on mount/demount tool

11) Bead breaker disks

12) Plastic guard on wheel holder base.

Perform the following:

• Clean with a dry cloth

• Restore a thin film of protective oil

on the following parts:

-) Wheel clamping hub nut

13) Vertical slide cylinder rods on tools

14) Front lifter pneumatic cylinder rods

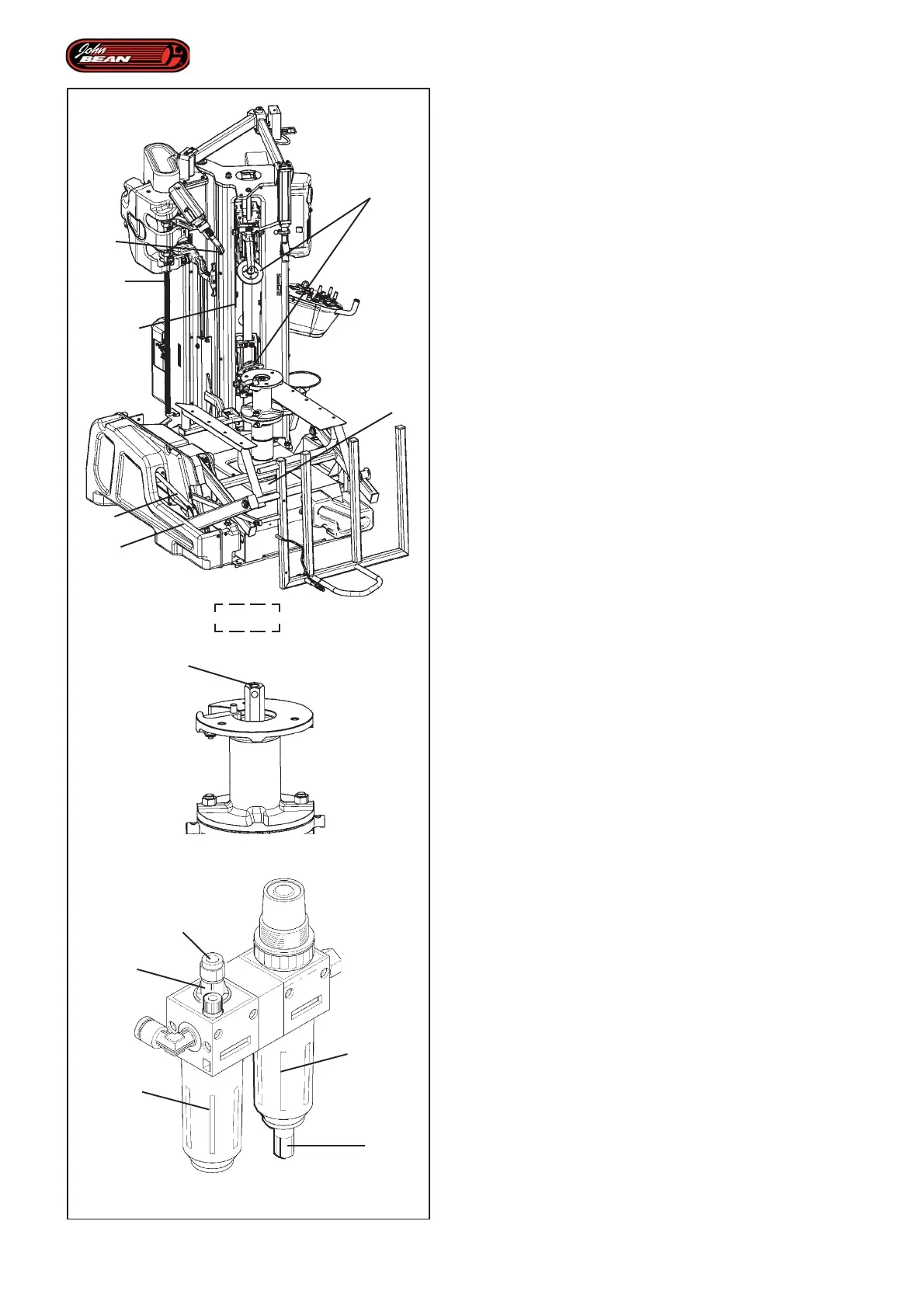

Figure 6.0-3

• Check that the lubrication unit is working properly.

One oil drop falling into the transparent cone G every

4-5 complete strokes of the bead breaker indicates

that the correct amount of oil is being dispersed in the

system. If necessary,

• Adjust the unit using the screw 'R' to correct the oil

flow so it is as indicated above.

Every day,

Perform the following:

• Clean with a dry cloth

the following parts:

Figure 6.0-1

10) Mount/demount tool plastic guards

11) Bead breaker disks

Perform the following:

• Clean with a dry cloth and compressed air.

the following parts:

Figure 6.0-2

15) Wheel clamping unit engage housing.

Figure 6.0-3

• Drain the water from the filter 'F' by pulling the fitting

'S' downwards.

• Check the level of oil in the lubricator.

Loading...

Loading...