140

POWERHEAD

ASSEMBLY

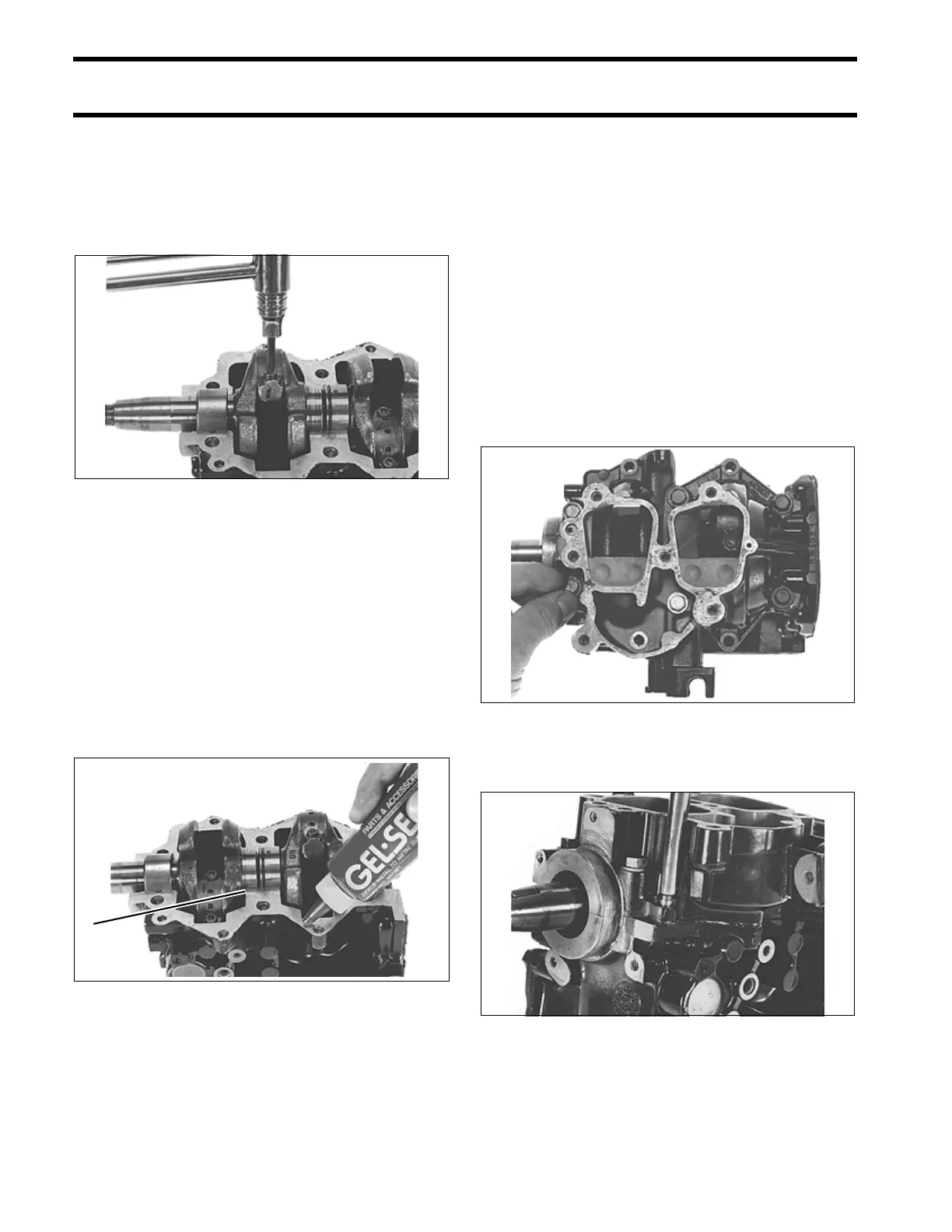

IMPORTANT: Replace connecting rod assem-

bly if proper cap and rod alignment cannot be

achieved.

Tighten the screws in stages to a final torque of 60

to 70 in. lbs. (7.0 to 7.5 N·m).

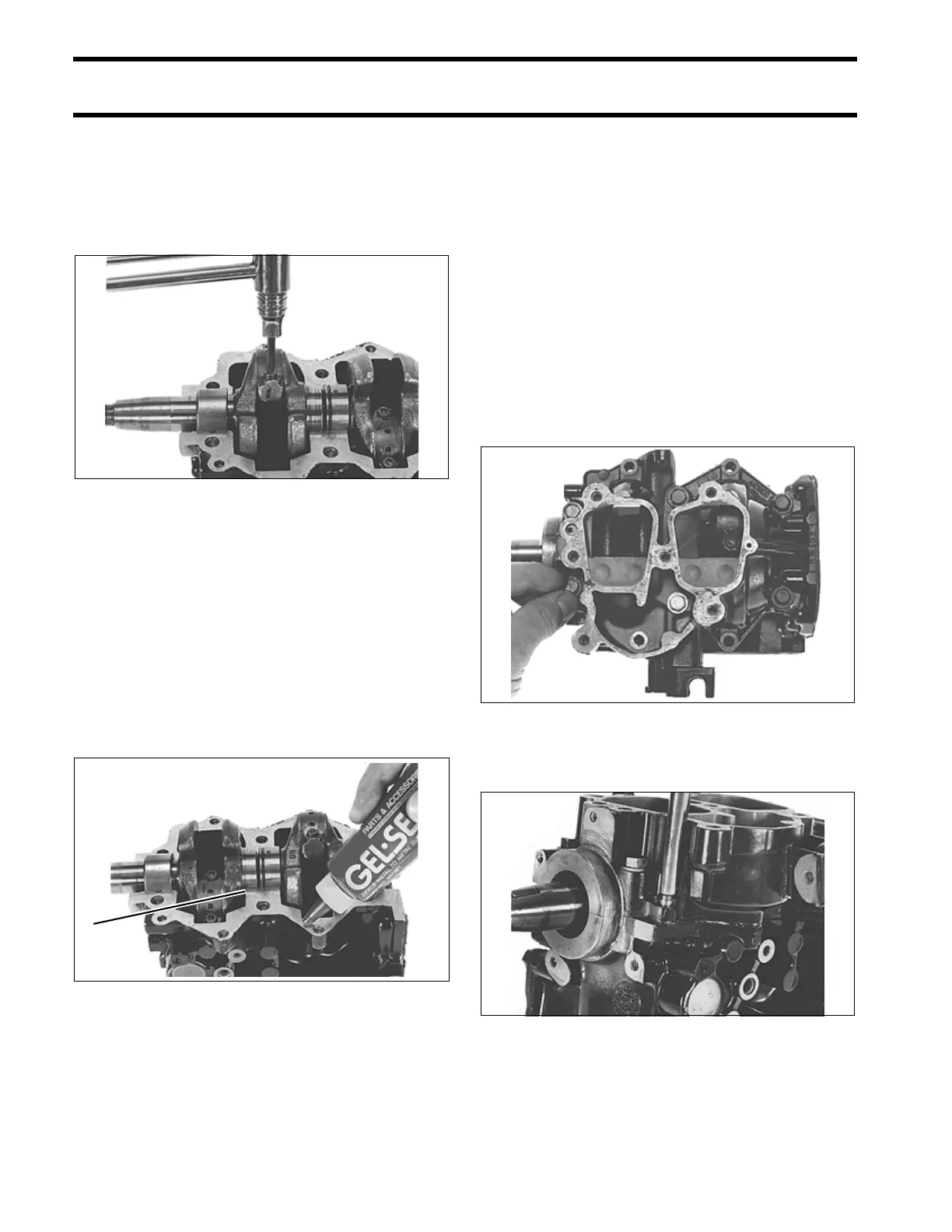

Thoroughly clean and degrease the mating

flanges of the crankcase and cylinder block with a

non-petroleum based solvent, such as isopropyl

alcohol or acetone, and let air dry.

Apply Locquic Primer to the mating flange of the

crankcase and let air dry.

Use a small brush to dab a thin, even coat of Gel-

Seal II sealant to the cylinder block mating flange.

The application must not come within 1/4 in. (6.4

mm) of the labyrinth seals and bearings.

IMPORTANT: Gel-Seal II has a shelf life of at

least one year when stored at room temperature.

Test the Gel-Seal II or replace it if the age of the

tube can not be determined. Using old Gel-Seal II

could cause crankcase air leaks.

IMPORTANT: If Locquic Primer is used, crank-

case halves must be assembled and tightened

within ten minutes after the Gel-Seal II has been

applied.

Lower the crankcase into place.

Lightly coat threads of the six main bearing

screws with Gel-Seal II. Install the screws finger

tight.

When the crankcase is seated, install and firmly

seat the crankcase taper pin.

Using a soft face mallet, lightly tap bottom of the

crankshaft to seat the lower main bearing.

32452

1. Labyrinth seal (grooves) 32451

1

32450

32378

Loading...

Loading...