Starting the machine and carrying out a trial run

1. Close all access doors, replace and secure all removable panels.

2. Open the user's shut-off valve between the machine and the air distribution network.

3. Switch on the power supply and reset the maintenance interval counter.

4. Start the machine and check the oil level again after about 10 minutes, topping up if necessary.

5. Switch off the machine and check visually for leaks.

10.16 Changing the oil filter

The machine must be isolated from the compressed air network and completely vented be‐

fore undertaking any work on the pressure system.

Material Spares

Cooling oil receptacle

Precondition The power supply isolating device is switched off,

the device is locked off,

the absence of any voltage has been verified.

The machine is fully vented,

the pressure gauge on the oil separator tank reads 0 bar.

CAUTION

There is risk of burns from hot components and oil!

➤ Wear long-sleeved clothing and gloves.

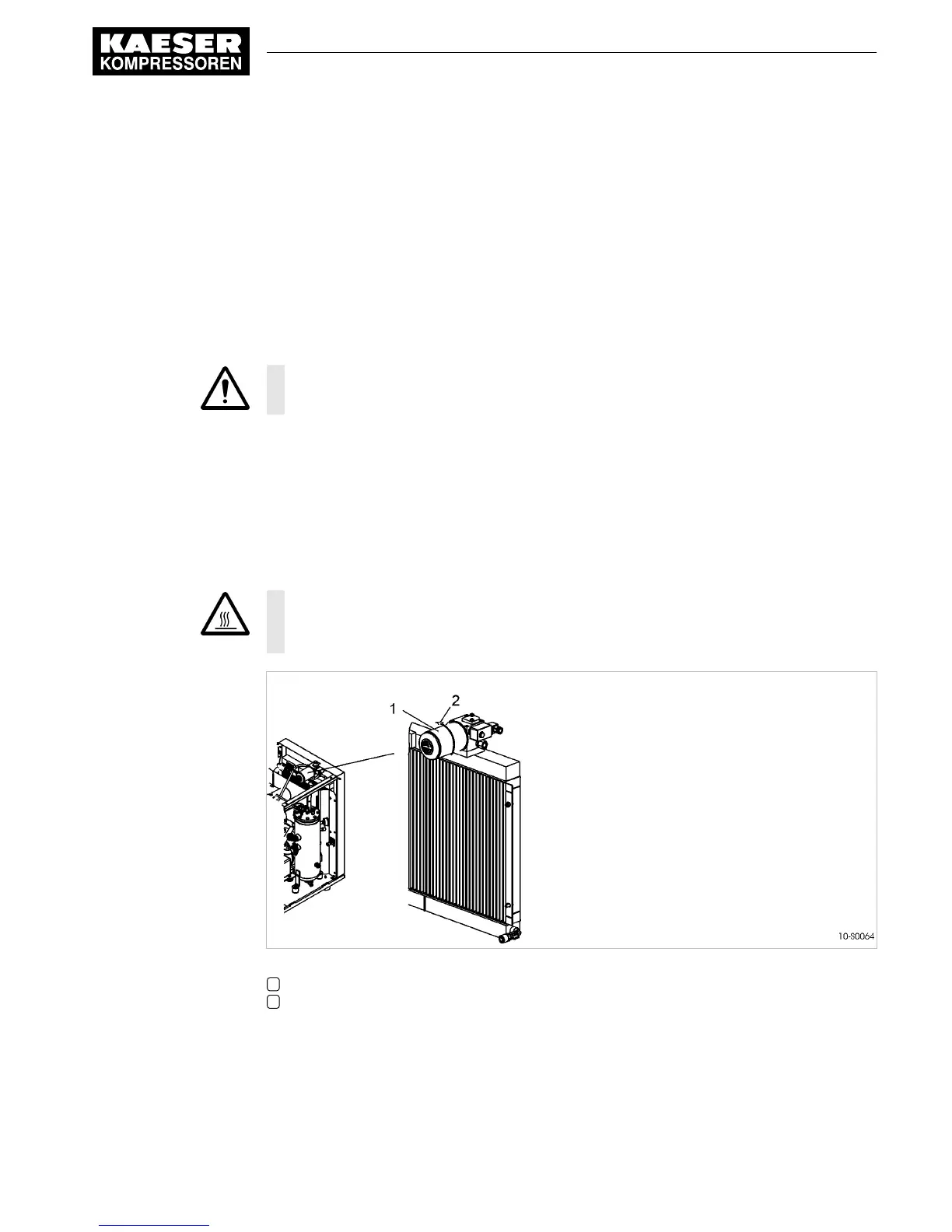

Fig. 29 Changing the oil filter

1 Oil filter

2 Direction to unscrew

10 Maintenance

10.16 Changing the oil filter

9_5717 20 E

Service Manual Screw Compressor

ASK T SIGMA CONTROL BASIC

77

Loading...

Loading...