Event Recognition and Fault Rectification

9 --- 44

9 Event Recognition and Fault Rectification

Inform KAESER service if the event cannot be rectified by the action suggested.

Do not attempt rectifications other than those given in this manual.

The measures valid for your machine are dependant on the individual equipment.

There are three types of event:

Description

Indicated by see chapter

An event that triggers an alarm (with automatic

shut---down)

Blinking red LED 9.1

An event that triggers a warning (no shut---

down)

Blinking yellow LED 9.2

Miscellaneous events (faults) No indication 9.3

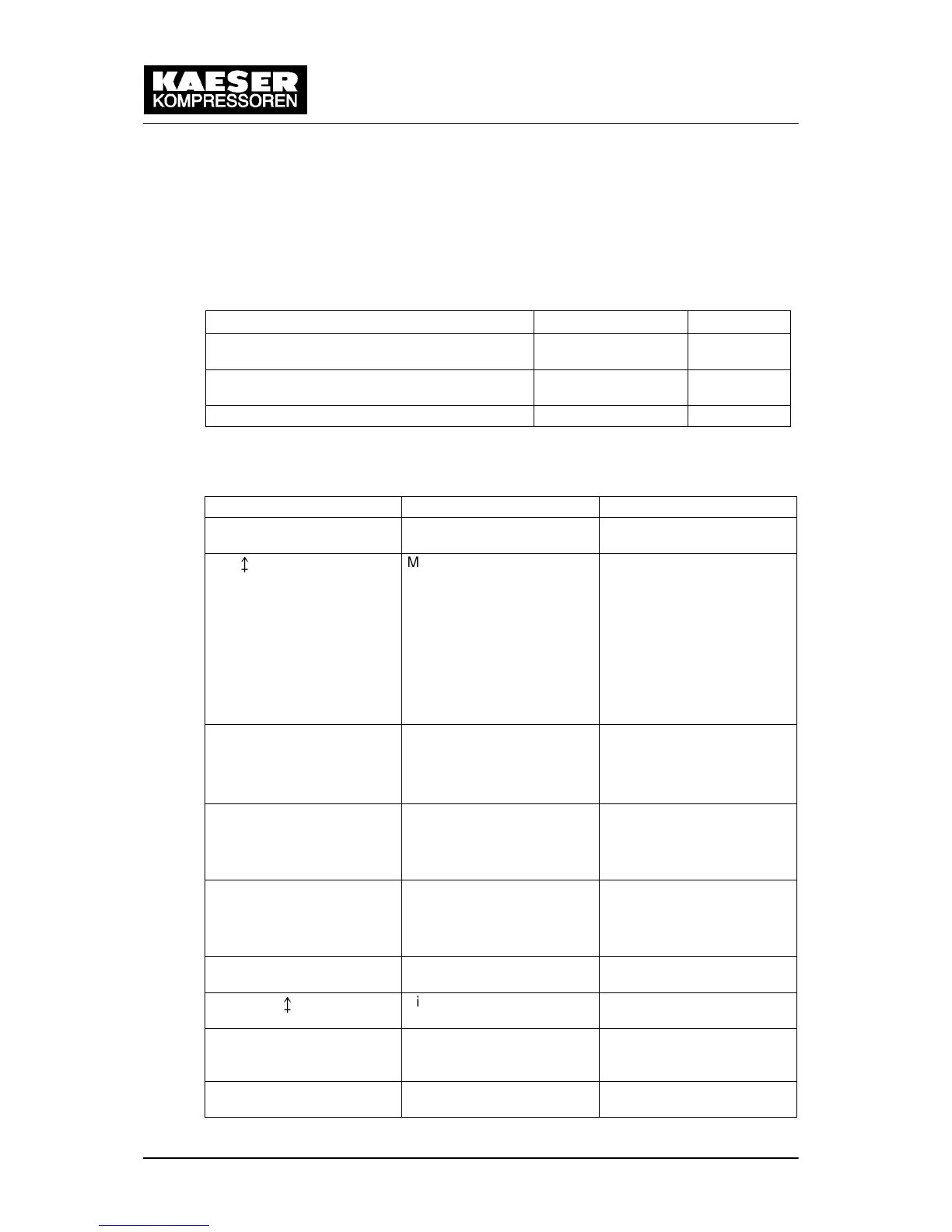

9.1 Alarm messages to the controller

(machine shut---down, red LED blinking)

Message

Possible cause Remedy

access doors Door open with the machine

running.

Close the door(s).

ADT

Maximum airend discharge

temperature exceeded.

Ensure adequate ventila-

tion.

Ensure that the permissible

room temperature is not ex-

ceeded.

Clean the cooler.

Cooling air outlet of the ma-

chine too near a wall.

Check the cooling oil level.

ADT dT/dt Maximum rise rate of airend

discharge temperature

(ADT) exceeded.

Check airend and piping to

airend.

Check the cooling oil level.

Check oil circulation.

AI 3/AI 4 error Line---break between the

analog input and the sen-

sor.

Short circuit to earth.

Check transducer connec-

tions and wiring.

AI 7/AI 8 error Line---break between the

analog input and the sen-

sor.

Short circuit to earth.

Check transducer connec-

tions and wiring.

airend rotation The drive motor is turning in

the wrong direction.

Change over phase lines L1

and L2.

air filter dp

Air filter clogged. Clean or renew the filter el-

ement.

backpressure Back pressure in the oil

separator tank caused by

poor venting.

Check venting line.

Buscontroller Bus link via the Profibus DP

interface

Check line and settings.

Loading...

Loading...