CAUTION

Replace bent or damaged cross tubes with original equipment parts

of the same length, diameter and threads. Do not attempt to

straighten a bent cross tube. Damage to components can result.

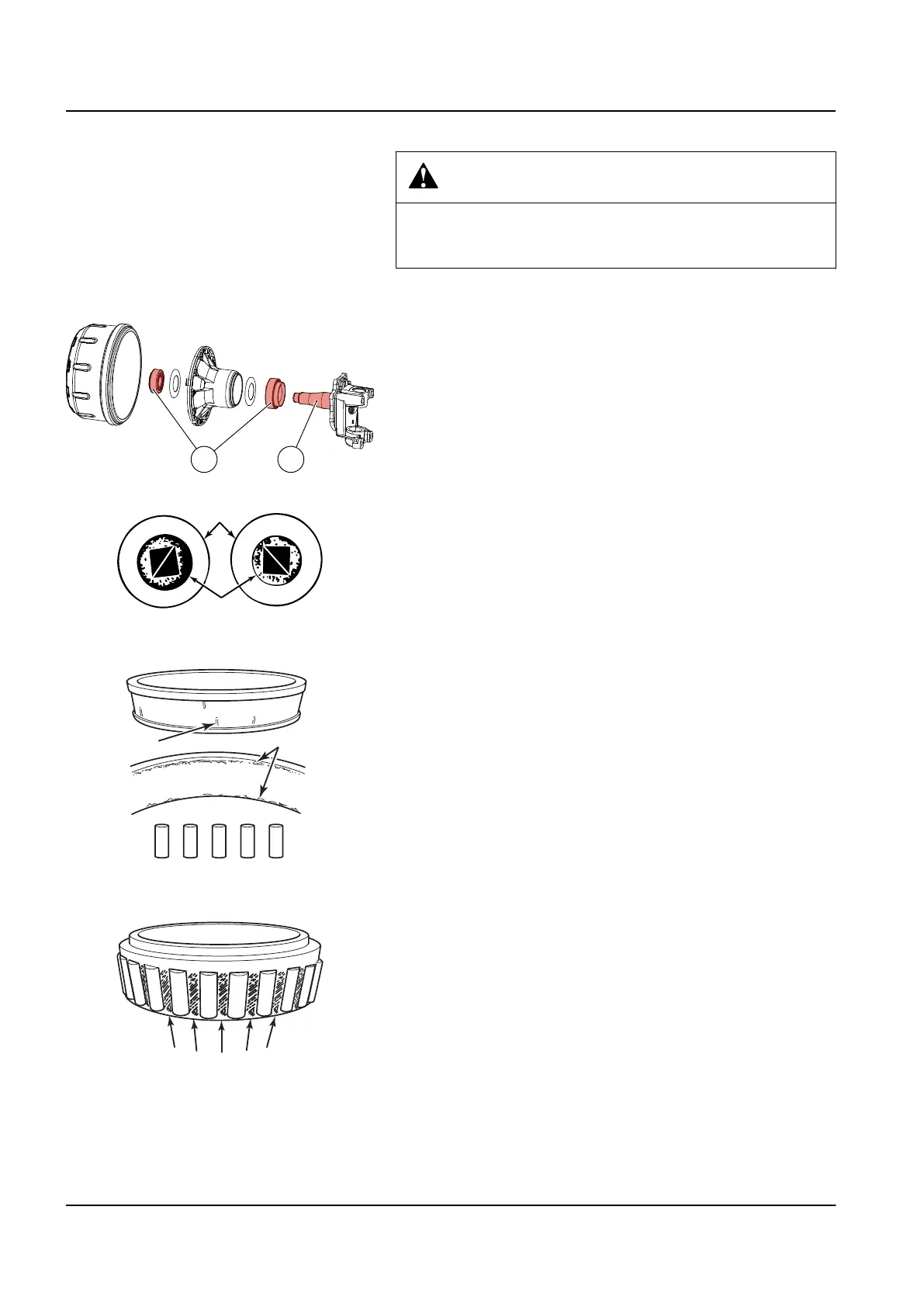

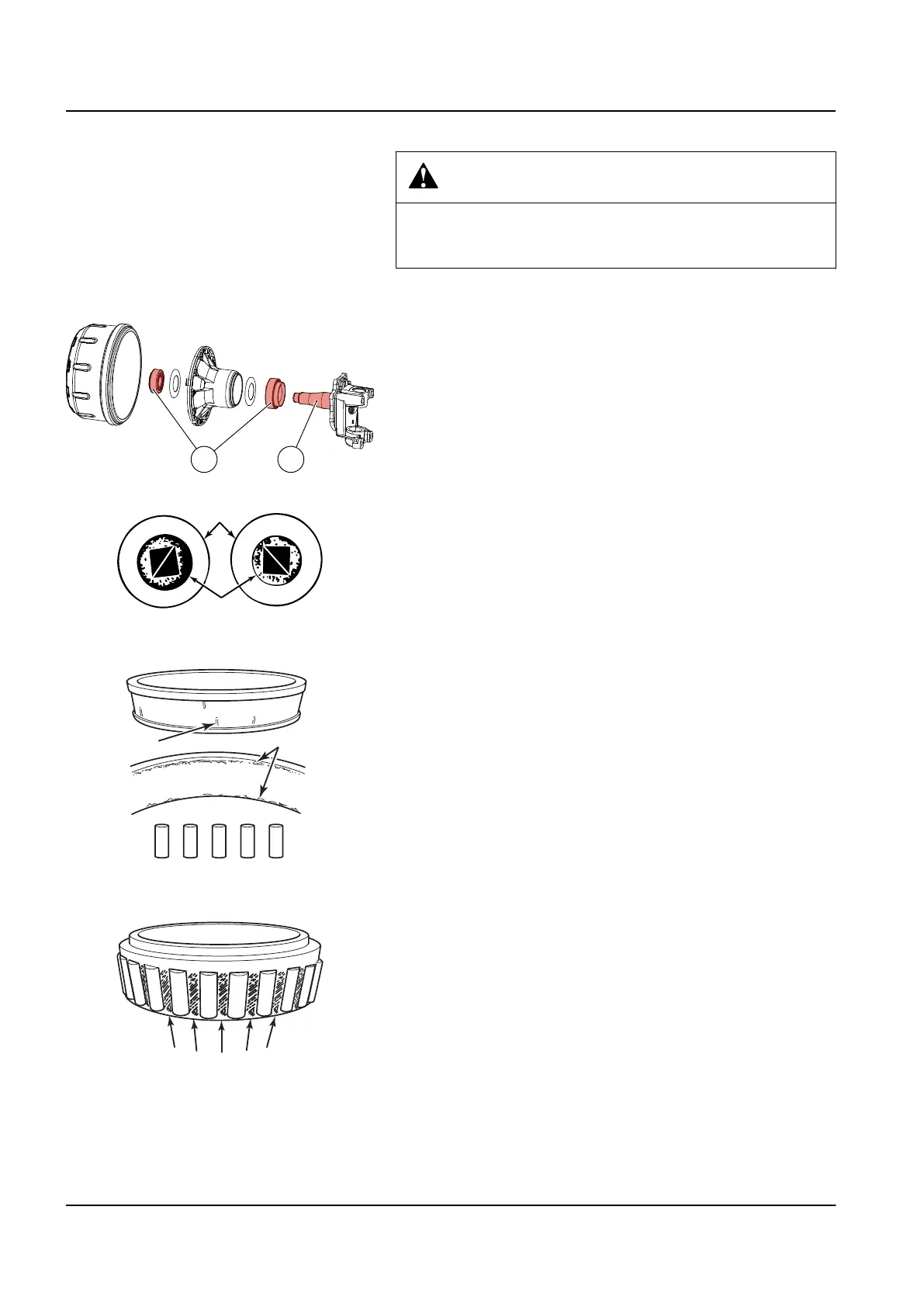

Examine axle bearings

Examine the axle bearings (A) when the hub is removed from the

knuckle spindle.

Lubricate the axle bearings (A) and surface of the knucke spindle

(B).

Examine the cup, the cone and the rollers and cage of all bearings.

If any of the following conditions exist, you must replace the bear‐

ing:

– The center of the large diameter end of the rollers is worn

level or below the outer surface.

– There is a visible roller groove in the cup or the cone inner

race surfaces. The groove can be seen at the small or large

diameter end of both parts.

– There are deep cracks or breaks in the cup, the cone

inner race or the roller surfaces.

– There are bright wear marks on the outer surface of the

roller cage.

4 5 Steering – 5.2 Power assisted system

TL2 Maintenance Manual

591 003 Default

Loading...

Loading...