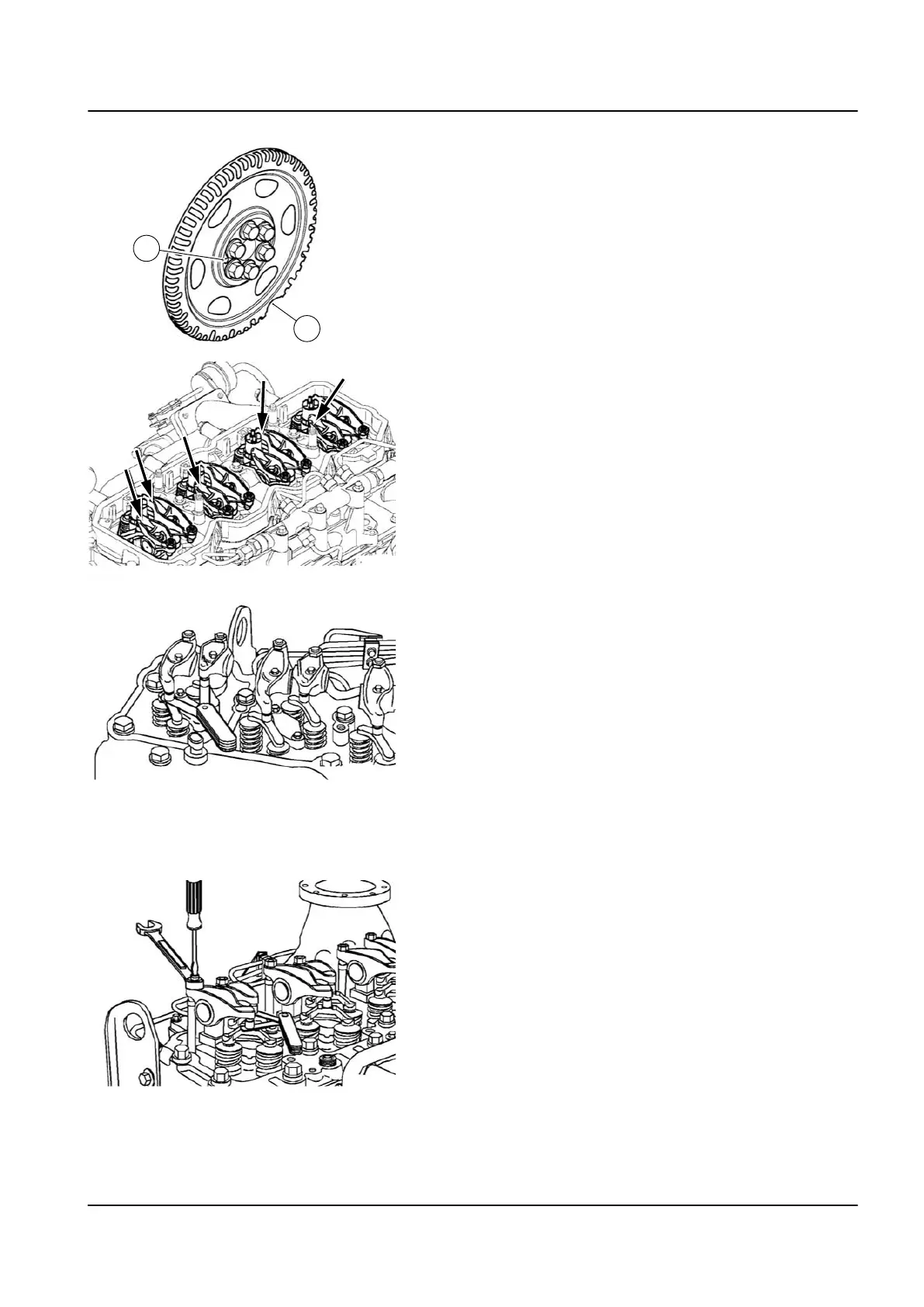

3 If no TDC mark is present on either the vibration damper or

the crankshaft speed indicator ring, align the large gap in the

crankshaft speed indicator ring to the 5 o'clock position (B).

The dowel pin will be visible in the 9 o'clock position (A).

Check that both number 1 cylinder rocker levers are loose. If

they are not loose, rotate the crankshaft 360 degrees and

check again.

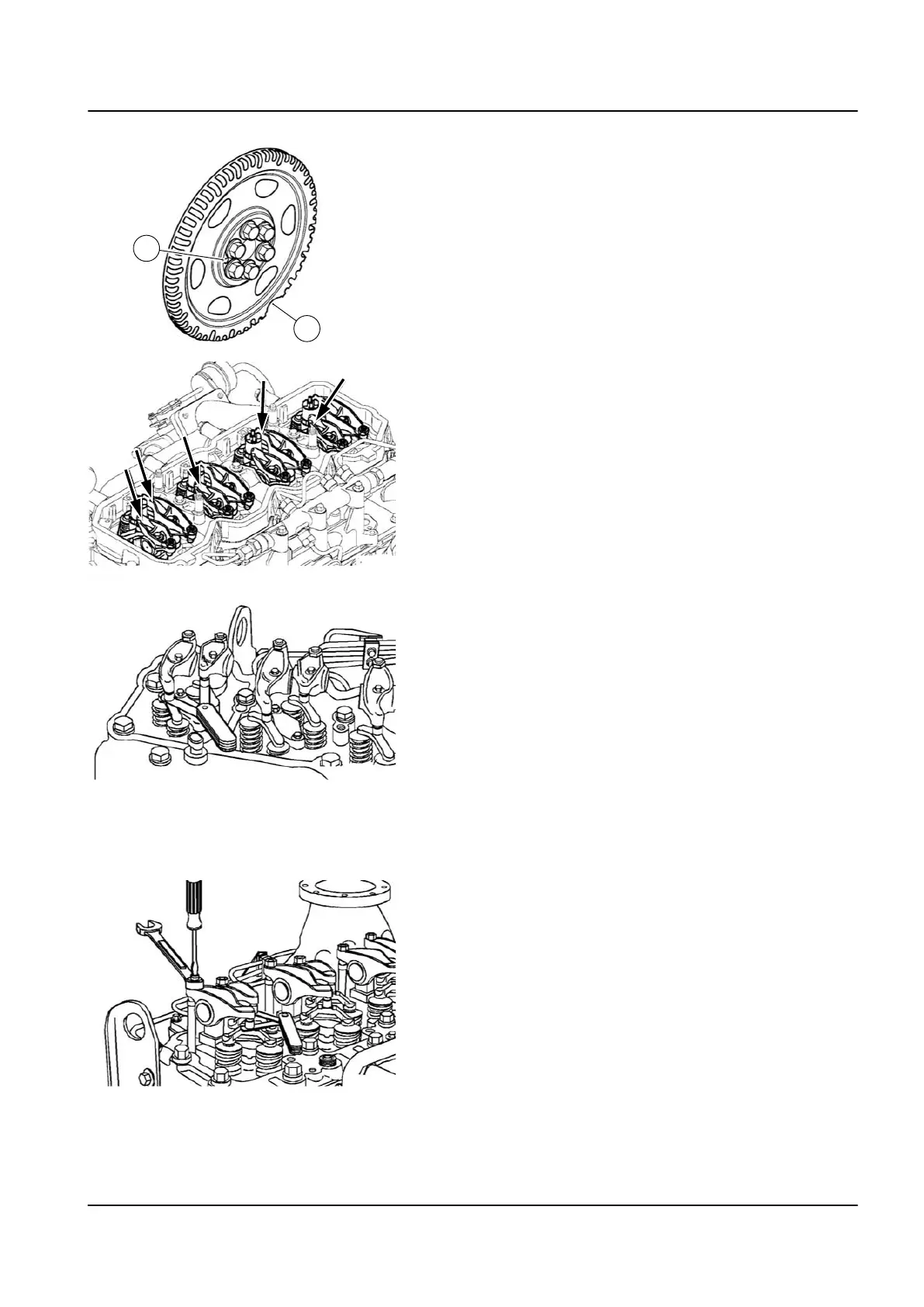

4 With the engine in this position, lash can be checked on the

following rocker arms:

(E = exhaust, I = intake)

Four-cylinder 1I, 1E, 2I and 3E

Six-cylinder 1I, 1E, 2I, 3E, 4I and 5E.

Lash Check Limits

mm in

Intake 0.152 MIN 0.006

0.381 MAX 0.015

Exhaust 0.381 MIN 0.015

0.762 MAX 0.030

NOTE

Examing the overhead setting is usually performed as part of a trou‐

bleshooting procedure, and resetting is not required during examina‐

tion, as long as the lash measurements are within the specifications

shown above.

5 Measure the valve lash (overhead set) by inserting a feeler

gauge between the crosshead and the rocker lever socket. If

the measurement is out of specification, loosen the locknut

and adjust the lash to nominal specifications.

NOTE

The clearance is correct when some resistance is “felt” when the

feeler gauge is slipped between the crosshead and the rocker lever

socket.

1 Engine – 1.5 Mechanical components of the engine 15

TL2 Maintenance Manual

591 003 Default

Loading...

Loading...