8 Kamstrup A/S • 5512887_B2_GB_09.2015

ULTRAFLOW® 54 · DN150-300

1.3 Stright inlet

ULTRAFLOW® 54 requires neither stright inlet nor outlet in order to fulfil the Mesuring

Instruments Directive (MID) 2004/22/ EC nd EN 1434:2007. Only in cse of hevy flow

disturbnces before the meter will stright inlet section be necessry. We recommend following

the guidelines in CEN CR 13582.

Optiml position cn be obtined by tking the below-mentioned instlltion methods into

considertion:

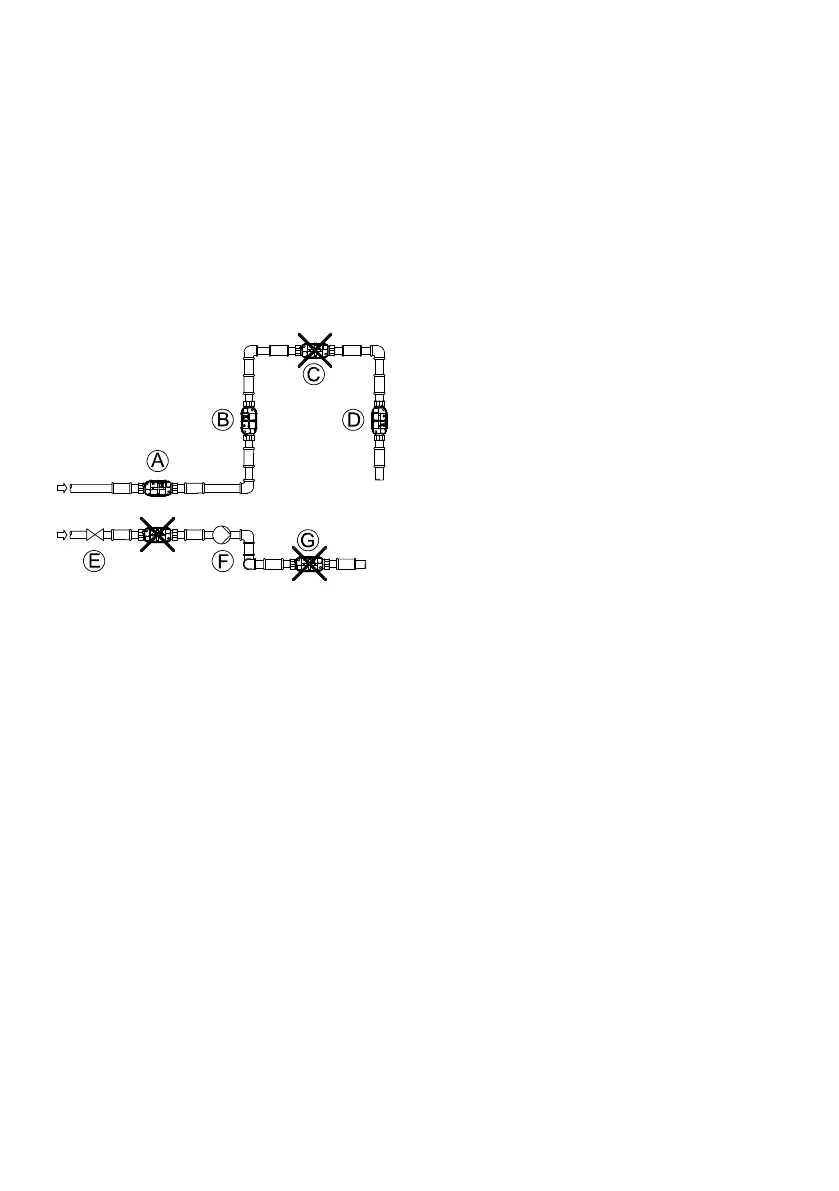

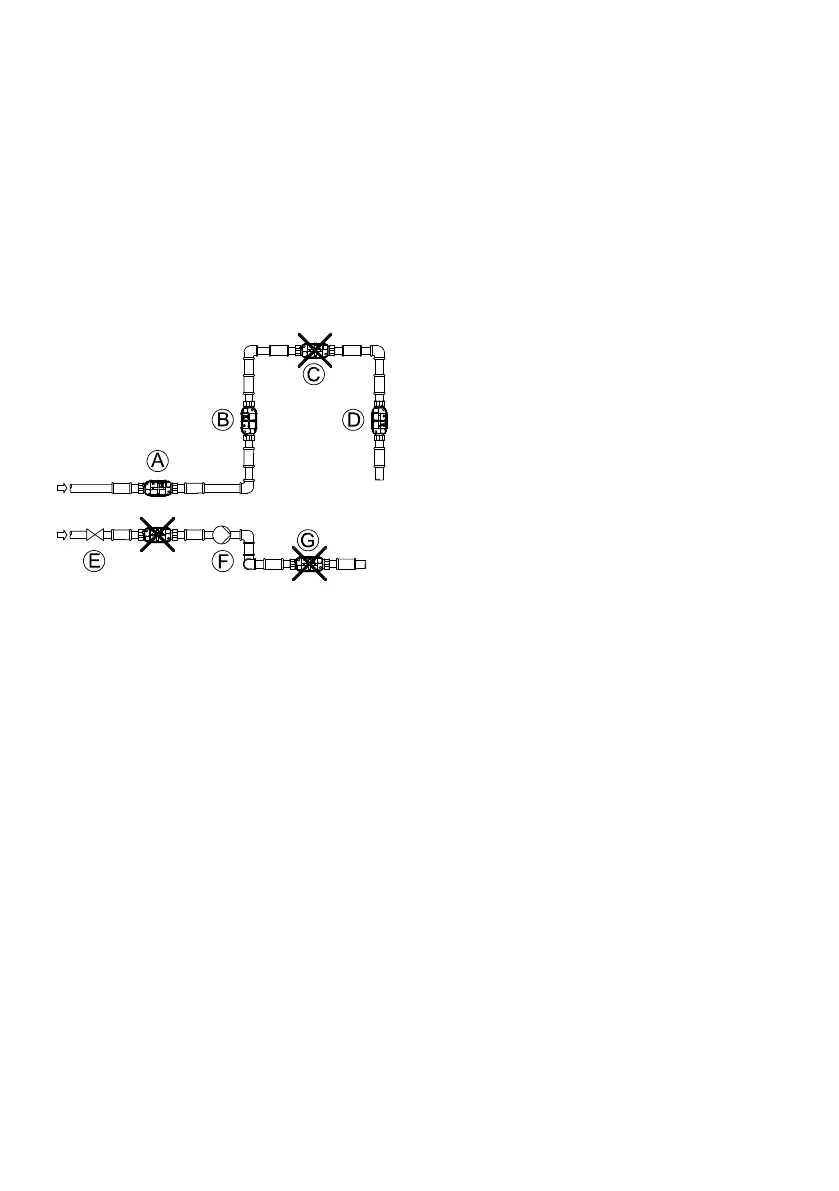

Figure 9

A Recommended flow sensor position.

B Recommended flow sensor position.

C Uncceptble position due to risk of ir build-

up.

D Acceptble in closed systems. Uncceptble

position in open systems due to risk of ir

build-up.

E A flow sensor should not be plced

immeditely fter vlve, except from closing

vlves (bll vlve type), which must be

completely open when not used for closing.

F A flow sensor should not be plced t the

suction side of pump.

G A flow sensor should not be plced fter

double bend in two plnes.

For generl informtion concerning instlltion see CEN report CEN CR 13582, Heat meter

installation. Instructions in selection, installation and use of heat meters.

1.4 Operting pressure

In order to prevent cvittion the bck pressure (the pressure t the flow sensor outlet) t

ULTRAFLOW® 54 must be min. 1.5 br t q

p

nd min. 2.5 br t q

s

. This pplies to tempertures up

to pprox. 80 °C.

Loading...

Loading...