20

Commissioning and conguration

ServoOne User Manual SERCOS II and III

ID no.: 1108.26B.3-00 Date: 04/2020

Commissioning and conguration

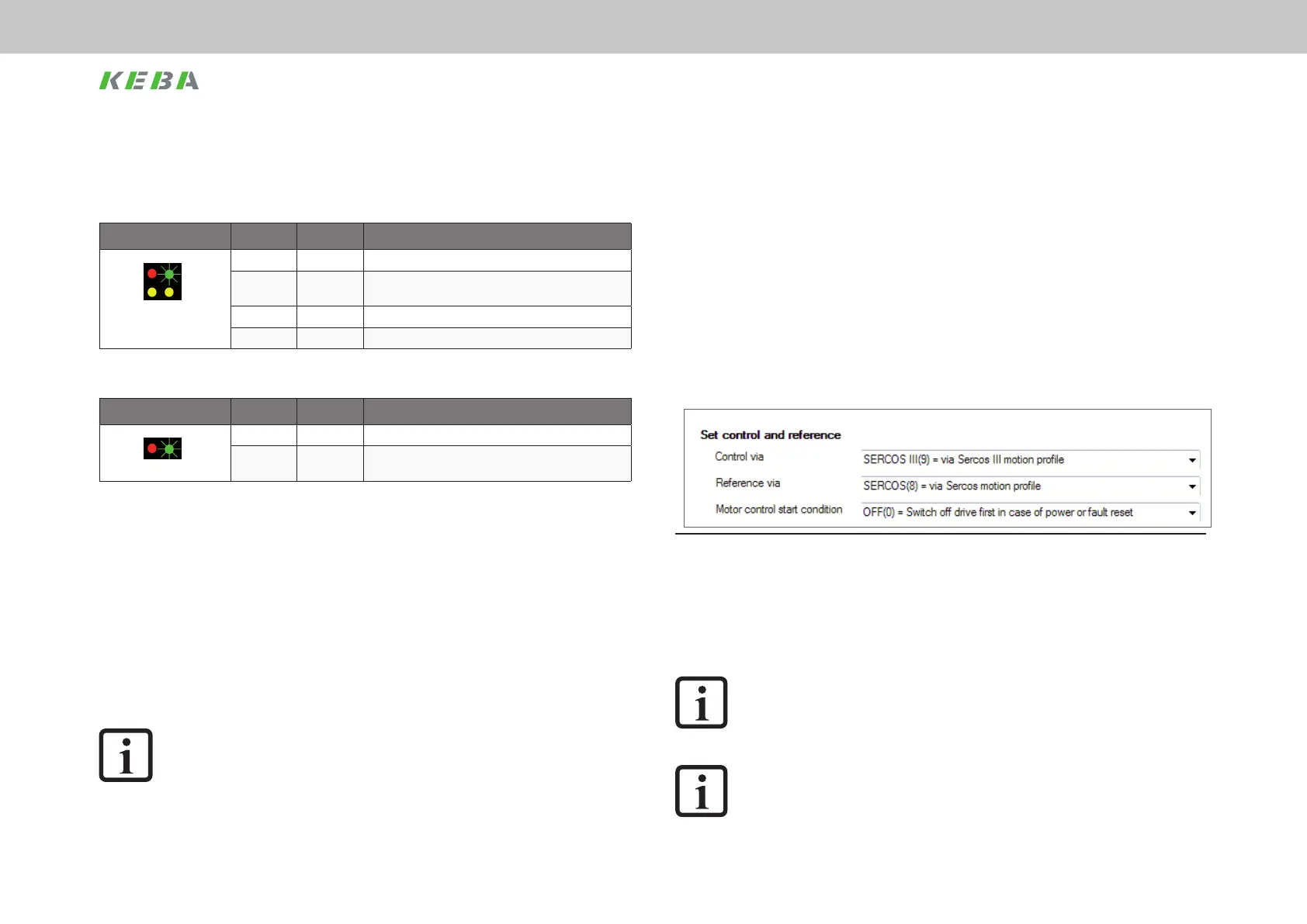

5.1.5 Diagnostic LEDs

Hardware variant 1

LED Colour Meaning

H5

H4

H6 H7

H4 Red Distortion LED, interference on the BUS

H5 Green Status of the SERCOS communication

phase (ashing code)

H6 Green Receiver LED, receiving telegrams

H7 Green Transmitter LED, sending telegrams

Hardware variant 2

LED Colour Meaning

H5

H4

H4 Red Distortion LED, interference on the BUS

H5 Green Status of the SERCOS communication

phase (ashing code)

5.1.6 Usage of the distortion indicator

After the drive address has been set, it should be checked whether an adequate

optical signal level is present at each bus user, i.e. whether the receiver is underdriven

or overdriven. The optical level is checked using the Distortion LED on the front of the

ServoOne (LED H4). Normally the Distortion LED is off. To check the optical level, all

drives in the ring are checked in the signal ow direction, starting from the transmitter

output on the master (see gure in sub-section "Connection for the bre optic cable").

The distortion indicators are to be checked in the "direction of the light", i.e. the rst

drive in the ring is to be checked rst. If its distortion indicator is off, check the next

drive. This procedure is continued to the last drive and then undertaken on the master

(controller).

Note:

The distortion indicator must not illuminate or glow.

5.2 SERCOS III

5.2.1 Conguring basic settings

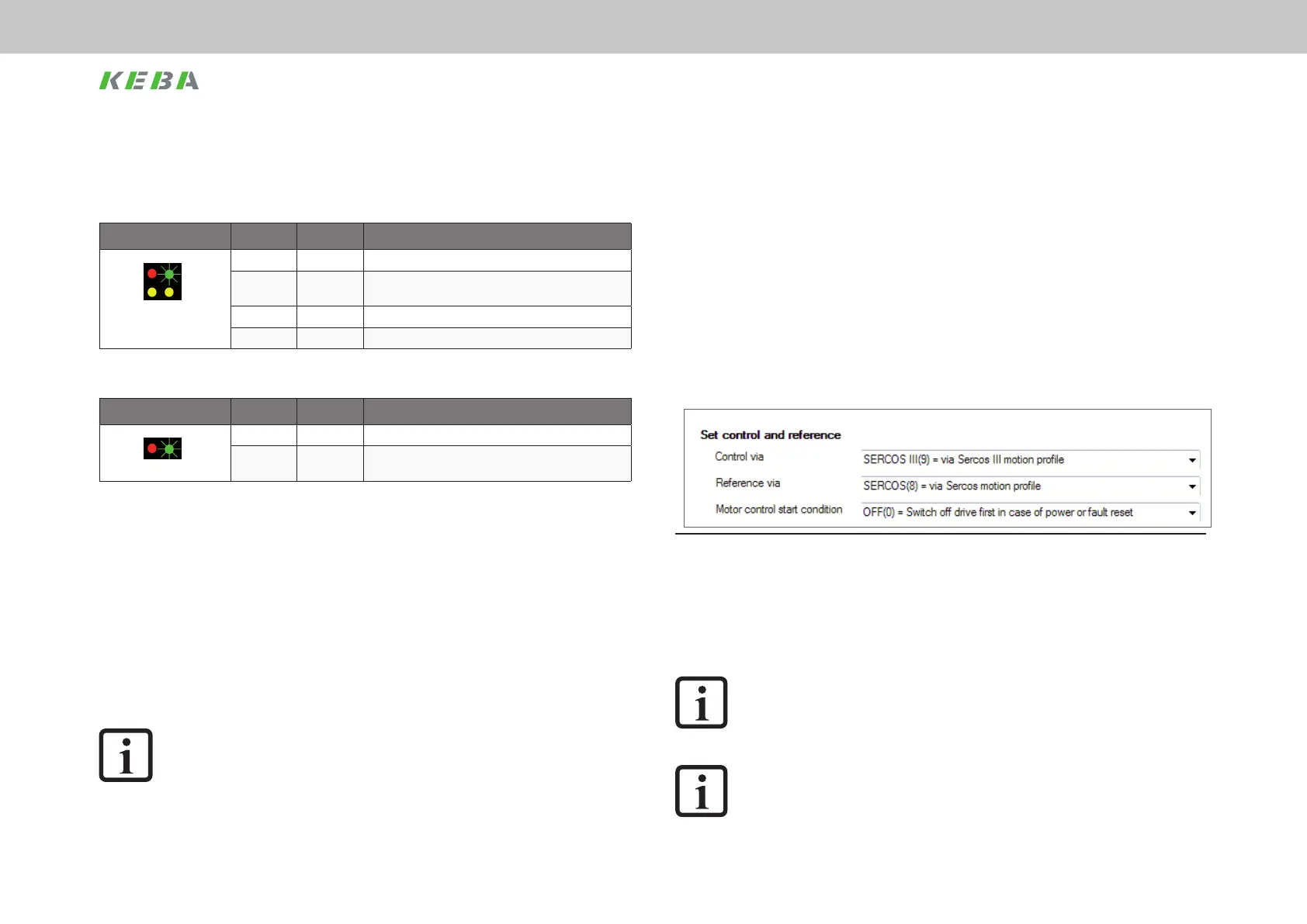

Setting the motion prole parameters

The basic drive settings must be congured as per the reference documents. Then the

following setting must be made with the aid of DriveManager so that it is possible to

change to operation via Sercos.

So that the drive can be controlled and moved via SERCOS III, the two parameters

control location selector P-159 MPRO_CTRL_SEL and reference value selector P-165

MPRO_REF_SEL must be set as per the gure below.

Figure 5.2 Basic settings, P-0159 and P-0165 with SERCOS III

Prerequisites:

y The drive is wired as per the operation manual and initial commissioning has

been undertaken.

y If electrical power is to be applied to the motor, the hardware enable (ENPO)

and the "STO (Safe Torque Off)" must also be connected correctly.

NOTE:

You will nd more detailed information on the optimisation of the control

function and control circuits in the application manual for the device.

NOTE:

For information on the topic of "Scaling", please read chapter 6.

Loading...

Loading...