device. When the instrument is in the talk-only mode, the

front panel TALK LED will turn on.

The instrument can be placed in the talk-only mode by enter-

ing one of the following parameters in the primary address

program:

40 Talk only mode with prefix on data string (Example:

NDCV--1.2345E-01

41 Talk only mode without prefix on data string (Example:

-1.2345E-01

To place the instrument in the talk-only mode, perform the

following steps:

1. Press the PROGRAM SELECT button so that the follow-

ing message is displayed:

IEEE 27

2. Press the up arrow V-SOURCE ADJUST button repeated-

ly until the desired talk-only parameter (40 or 41) is

shown.

3. To exit the program, press SHIFT then SELECT EXIT. The

unit is now programmed for the talk-only mode, and it

will remain programmed in this manner even if the power

is turned off.

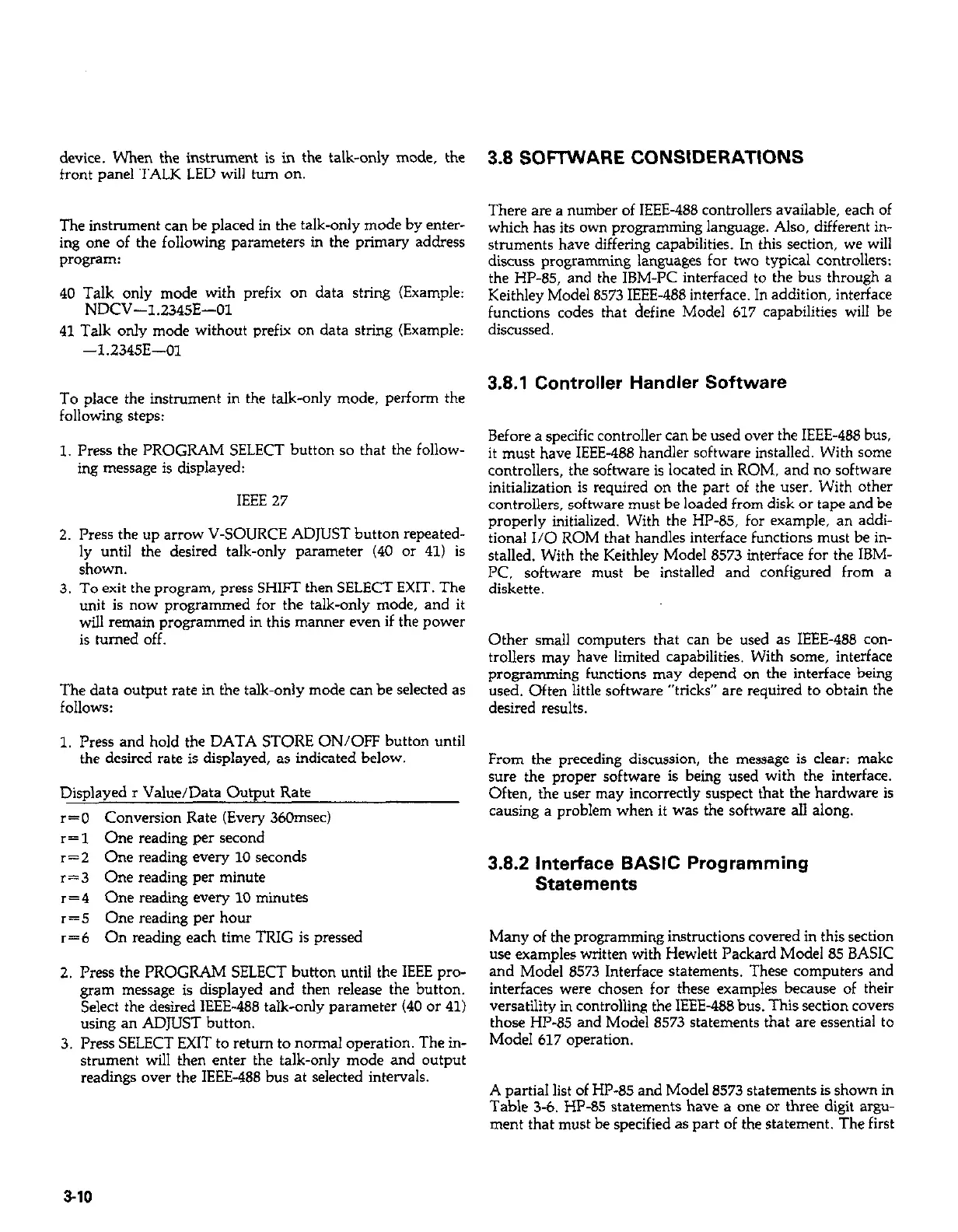

The data output rate in the talk-only mode can be selected as

follows:

1. Press and hold the DATA STORE ON/OFF button until

the desired rate is displayed, as indicated below.

Displayed r Value/Data Output Rate

r=O

r=l

r=2

r=3

r=4

r=5

r=6

Conversion Rate (Every 36Omsec)

One reading per second

One reading every 10 seconds

One reading per minute

One reading every 10 minutes

One reading per hour

On reading each time TRIG is pressed

2. Press the PROGRAM SELECT button until the IEEE pro-

gram message is displayed and then release the button.

Select the desired IEEE-488 talk-only parameter (40 or 41)

using an ADJUST button.

3. Press SELECT EXIT to return to normal operation. The in-

strument will then enter the talk-only mode and output

readings over the IEEE-488 bus at selected intervals.

3.8 SOFIWARE CONSIDERATIONS

There are a number of IEEE-488 controllers available, each of

which has its own programming language. Also, different in-

struments have differing capabilities. In this section, we will

discuss programming languages for two typical controllers:

the HP-85, and the IBM-PC interfaced to the bus through a

Keithley Model 8573 IEEE-488 interface. In addition, interface

functions codes that define Model 617 capabilities will be

discussed.

3.8.1 Controller Handler Software

Before a specific controller can be used over the IEEE-488 bus,

it must have IEEE-488 handler software installed. With some

controllers, the software is located in ROM, and no software

initialization is required on the part of the user. With other

controllers, software must be loaded from disk or tape and be

properly initialized. With the HP-85, for example, an addi-

tional I/O ROM that handles interface functions must be in-

stalled. With the Keithley Model 8573 interface for the IBM-

PC, software must be installed and configured from a

diskette.

Other small computers that can be used as IEEE-488 con-

trollers may have limited capabilities. With some, interface

programming functions may depend on the interface being

used. Often little software “tricks” are required to obtain the

desired results.

From the preceding discussion, the message is clear: make

sure the proper software is being used with the interface.

Often, the user may incorrectly suspect that the hardware is

causing a problem when it was the software all along.

3.8.2 Interface BASIC Programming

Statements

Many of the programming instructions covered in this section

use examples written with Hewlett Packard Model 85 BASIC

and Model 8573 Interface statements. These computers and

interfaces were chosen for these examples because of their

versatility in controlling the IEEE-488 bus. This section covers

those HP-85 and Model 8573 statements that are essential to

Model 617 operation.

A partial list of HP-85 and Model 8573 statements is shown in

Table 3-6. HP-85 statements have a one or three digit argw

ment that must be specified as part of the statement. The first

310

Loading...

Loading...