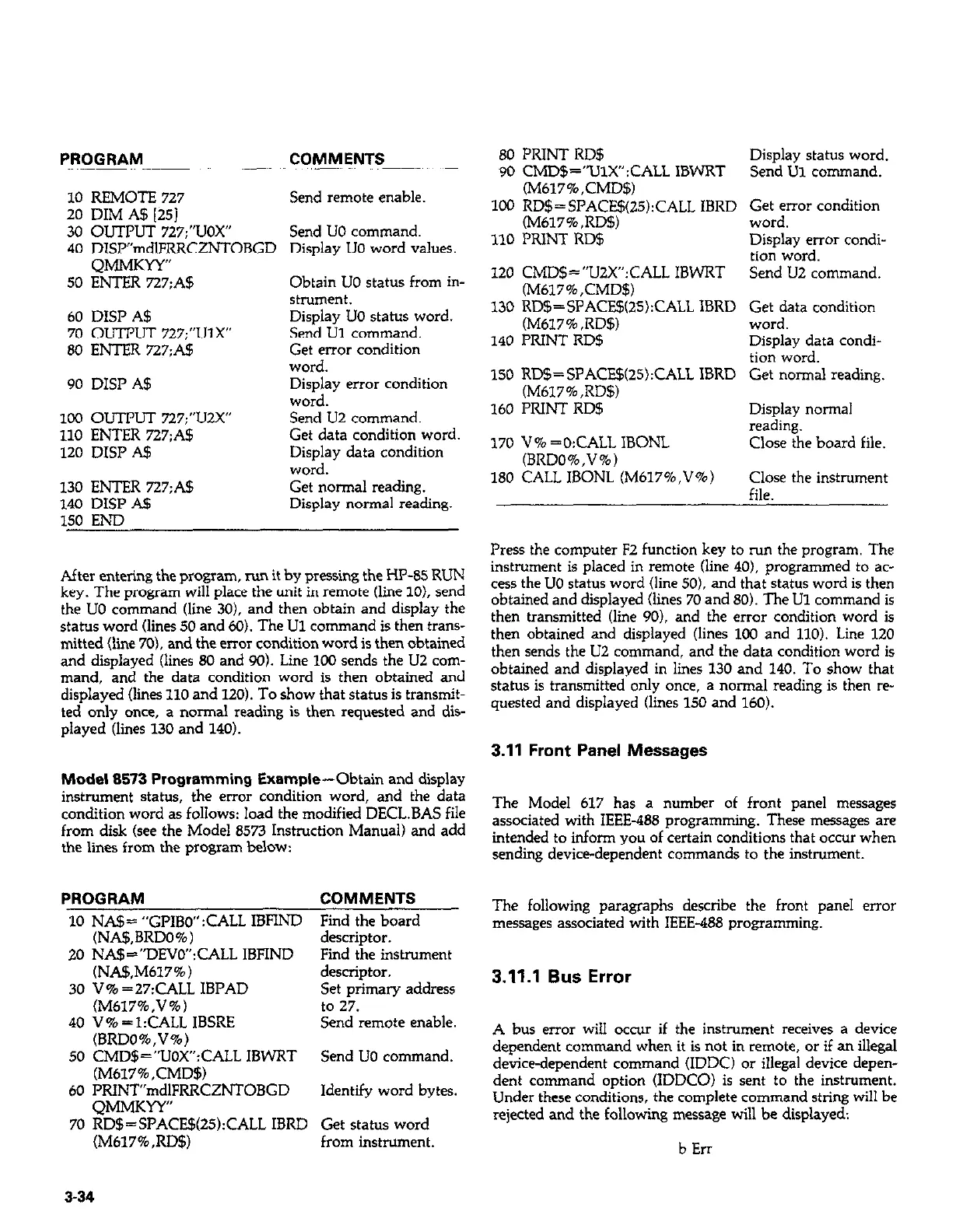

PROGRAM COMMENTS

10 REMOTE 727

20 DIM AS 1251

Send remote enable.

30 OuTPIJT 727:“UOX” Send UO command.

40 DW”mdlFRRCZNTOBGD Display UO word values

QMMKYY”

50 ENTER 727;A$

Obtain UO status from in-

strument.

Display UO status word

Send U1 command.

Get error condition

word.

Display error condition

word.

Send U2 command.

Get data condition word.

Display data condition

word.

Get normal reading.

Display normal reading.

60 DISP A$

70 OUTPUT 727;“Ulx”

80 ENTER 727;A$

90 DISP A$

100 OUTPUT 727:“U2X”

110 ENTER 727;A!J

120 DISP A$

130 EmR 727:A$

140 DISP A$

150 END

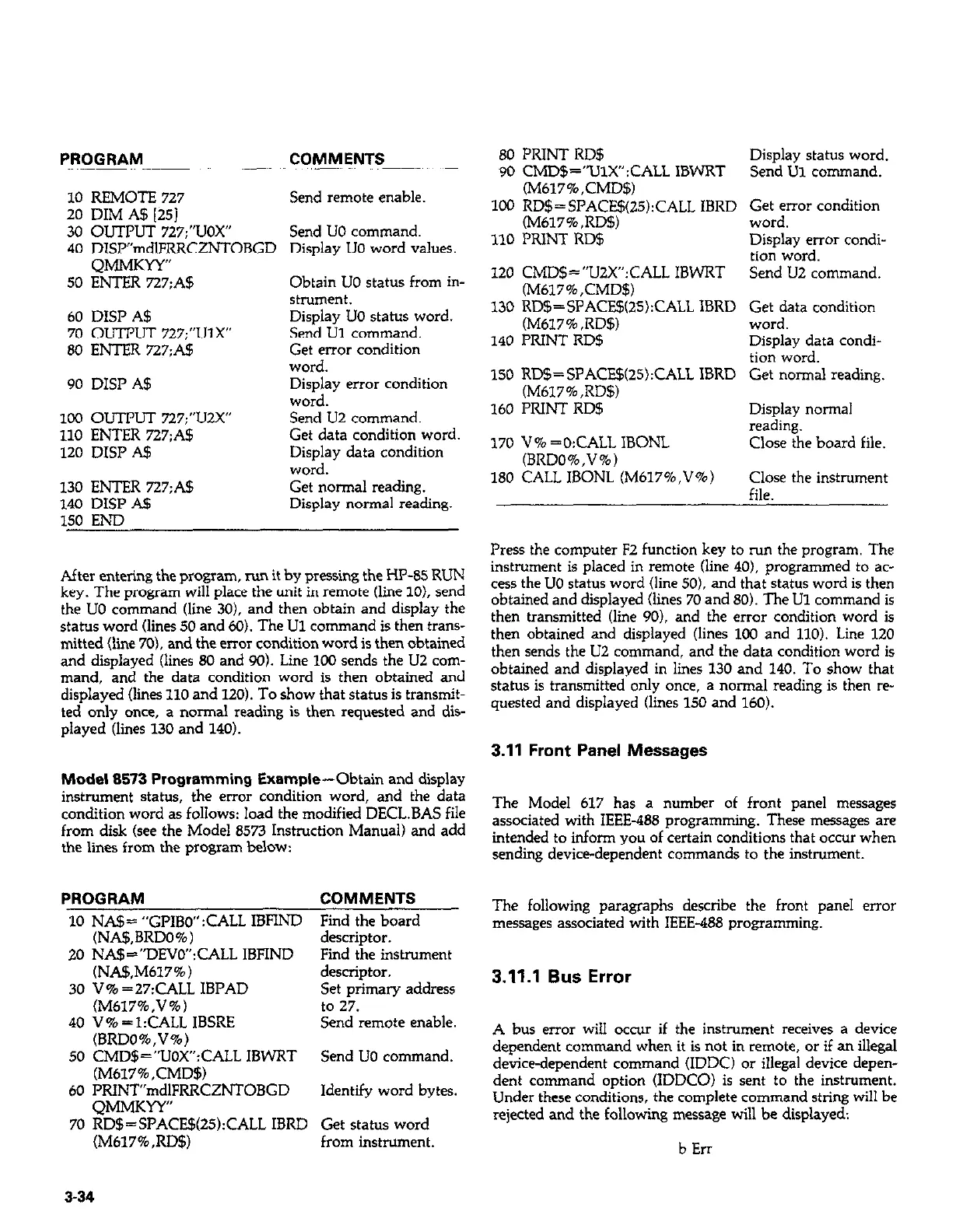

80 PRINT RD$

90 CMD$=“UlX”:CALL IBWRT

(M617%,CMD5)

100 RD$=SPACE$(ZS):CALL IBRD

(M617%,RD$)

1.10 PRINT RD$

120 CMD$=“UZX”:CALL IBWRT

(M617%,CMD$)

130 RD$=SPACE$(2S):CALL IBRD

(M617%,RD$)

140 PRIh’T RD$

150 RD$= SPACE$(25):CALL IBRD

(M617%,RD$)

160 PRINT RD$

170 V% =O:CALL IBONL

(BRDO%,V%)

180 CALL IBONL (M617%,V%)

Display status word.

Send Ul command.

Get error condition

word.

Display error condi-

tion word.

Send IJ2 command.

Get data condition

word.

Display data condi-

tion word.

Get normal reading.

Display normal

reading.

Close the board file.

Close the instrument

file.

Press the conmuter F2 function kev to run the moeram. The

. ”

After entering the program, run it by pressing the HP-85 RUN

instrument is placed in remote (line 40). programmed to ac-

key. The program will place the unit in remote (line 10). send

cess the UO status word (line 50). and that status word is then

the UO command (line 30). and then obtain and display the

obtained and displayed (lines 70 and 80). The Ul command is

status word (lines 50 and 60). Th e Ul command is

then trans-

then transmitted (line 90). and the error condition word is

mitted (line 70). z

md the error condition word is thj en obtained

then obtained and displayed (lines 100 and 110). Line 120

and displayed (lines 80 and 90). Line 100 sends the U2 com-

then sends the U2 command, and the data condition word is

mand, and the data condition word is then obtained and

obtained and displayed in lines 130 and 140. To show that

displayed (lines 110 and 120). To show that status is transmit-

status is transmitted only once, a normal reading is then re-

ted only once, a normal reading is then requested and dis-

quested and displayed (lines 150 and 160).

played (lines 130 and 140).

3.11 Front Panel Messages

Model 8573 Programming Example-Obtain and display

instrument status, the error condition word, and the data

condition word as follows: load the modified D--’ - IS file ‘tCL.LI~

The Model 617 has a number of front panel messages

from disk (see the Model 8573 Instruction Manual) and add

associated with IEEE-488 programming. These messages are

the lines from the program below:

intended to inform you of certain conditions that occur when

sending device-dependent commands to the instrument.

PROGRAM

COMMENTS

10 NA!J= “GPIBO” :CALL IBFIND Find the board

(NA$,BRDO%) descriptor.

20 NA$=“DEVO”:CALL IBFIND Find the instrument

(NA!f+M617%)

30 V% =27:CALL IBI’AD

(M617%,V%)

40 V%=l:CALL IBSRE

descriptor.

Set primary address

to 27.

Send remote enable.

(BRDO%,V%)

50 CMD$=“LIOX”:CALL IBWRT Send UO command.

(M617%,CMD$)

60 PRINT”mdlFRRCZNTOBGD Identifv word bvtes.

QMMKYY”

70 RD$=SPACE$QS):CALL IBRD Get status word

(M617%,RD$) from instrument.

The following paragraphs describe the front panel error

messages associated with IEEE-488 programming.

3.11.1 Bus Error

A bus error will occur if the instrument receives a device

dependent command when it is not in remote, or if an illegal

device-dependent command (IDDC) or illegal device depen-

dent command option (IDDCO) is sent to the instrument.

Under these conditions, the complete command string will be

rejected and the following message will be displayed:

b Err

3-34

Loading...

Loading...