Gl =Send reading without prefix. Example: -l.Z3456E+OO

GZ=Send reading with prefix and suffix when in BI (data

store) mode. Example:

NDCV-1.23456E+OO,023. In this example, memory loca-

tion 23 is being accessed.

Upon power up, or after the instrument receives a DCL or

SDC command, the instrument will be in the GO mode.

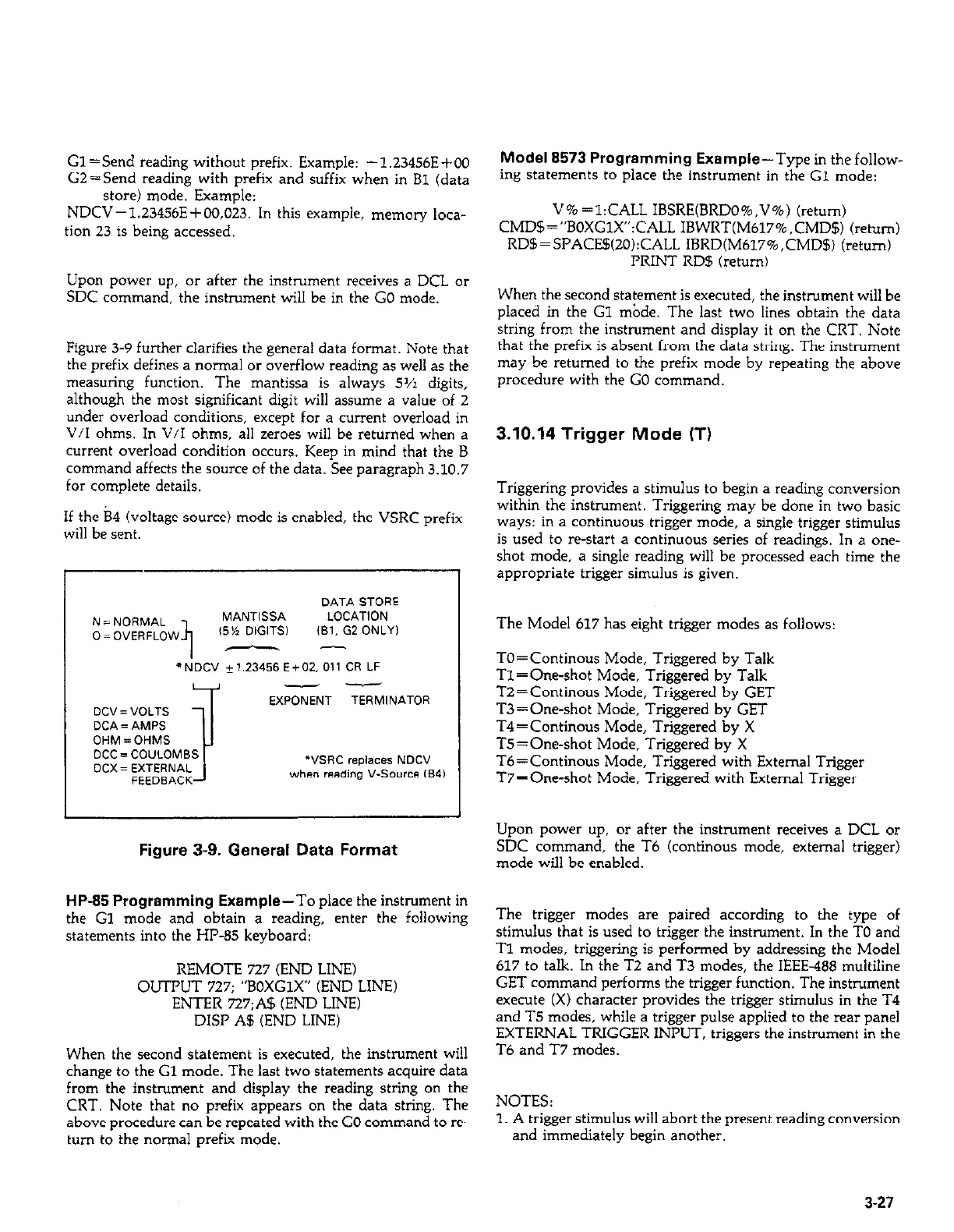

Figure 3-9 further clarifies the general data format. Note that

the prefix defines a normal or overflow reading as well as the

measuring function. The mantissa is always 5~2 digits,

although the most significant digit will assume a value of 2

under overload conditions, except for a current overload in

V/I ohms. In V/I ohms, all zeroes will be returned when a

current overload condition occurs. Keep in mind that the B

command affects the source of the data. See paragraph 3.10.7

for complete details.

If the B4 (voltage source) mode is enabled, the VSRC prefix

will be sent.

DATA STORE

I

N = NCIRMAL

II

MANTISSA

LOCATION

0 = OVERFLOW

(5% DIGITS1

,B,. G2 ONLY,

I

I

--

“NE” *1.23456 E+m. 011 CR LF

4

--

I

EXPONENT TERMlNATOR

DC”= VOLTS

DCA = AMPS

OHM=OHMS

DCC = CO”LOMBS

DCX= EXTERNAL

““SW replaces NDC”

when reading V-Source CB4)

Figure 3-9. General Data Format

HP-85 Programming Example-To place the instrument in

the Gl mode and obtain a reading, enter the following

statements into the HP-85 keyboard:

REMOTE 727 (END LINE)

OUTPUT 727; “BOXGlX” (END LINE)

ENTER 727;A$ (END LINE)

DISP A5 (END LINE)

When the second statement is executed, the instrument will

change to the Cl mode. The last two statements acquire data

from the instrument and display the reading string on the

CRT. Note that no prefix appears on the data string. The

above procedure can be repeated with the GO command to re-

turn to the normal prefix mode.

Model 8573 Programming Example-Type in thefollow-

ing statements to place the instrument in the G1 mode:

V% =l:CALL IBSRE(BRDO%,V%) (return)

CMD$=“BOXGlX”:CALL IBWRT(M617%,CMD$) (return)

RDB=SPACE5(2O):CALL IBRD(M617%,CMD$) (return)

PRINT RD5 (return)

When the second statement is executed, the instrument will be

placed in the Gl &de. The last two lines obtain the data

string from the instrument and display it on the CRT. Note

that the prefix is absent from the data string. The instrument

may be returned to the prefix mode by repeating the above

procedure with the GO command.

3.10.14 Trigger Mode (T)

Triggering provides a stimulus to begin a reading conversion

within the instrument. Triggering may be done in two basic

ways: in a continuous trigger mode, a single trigger stimulus

is used to restart a continuous series of readings. In a one-

shot mode, a single reading will be processed each time the

appropriate trigger simulus is given.

The Model 617 has eight trigger modes as follows:

TO=Continous Mode, Triggered by Talk

Tl =One-shot Mode, Triggered by Talk

T2=Continous Mode, Triggered by GET

T3 = One-shot Mode, Triggered by GET

T4=Continous Mode, Triggered by X

T5=Oreshot Mode, Triggered by X

Tb=Continous Mode, Triggered with External Trigger

Ti’=One-shot Mode, Triggered with External Trigger

Upon power up, or after the instrument receives a DCL or

SDC command, the T6 (continous mode, external trigger)

mode will be enabled.

The trigger modes are paired according to the type of

stimulus that is used to trigger the instrument. In the TO and

Tl modes, triggering is performed by addressing the Model

617 to talk. In the T2 and T3 modes, the IEEE-488 multiline

GET command performs the trigger function. The instrument

execute (X) character provides the trigger stimulus in the T4

and T5 modes, while a trigger pulse applied to the rear panel

EXTERNAL TRIGGER INPUT, triggers the instrument in the

T6 and T7 modes.

NOTES:

1. A trigger stimulus will abort the present reading conversion

and immediately begin another.

3-27

Loading...

Loading...