2. The front panel TRIG button will trigger the instrument

regardless of the selected trigger mode, unless LLO is in ef-

fect.

3. Serial polling usually addresses the instrument to talk. This

talk command will trigger the instrument in the TO and Tl

modes.

HP-85 Programming Example-Place the instrument in

the one-shot on talk mode with the following statements:

REMOTE 727 (END LINE)

OUTPUT 727:“TlX” (END LINE)

One reading can now be triggered and the resulting data ob-

tained with the following statements:

ENTER 727;A!$ (END LINE)

DISP A$ (END LINE)

In this example, the ENTER statement addresses the Model

617 to talk, at which point a single reading is triggered. When

the reading has been processed (360msec later), it is sent out

over to the bus to the computer, which then displays the

result.

Model 8573 Programming Example--Place the instru-

ment in the Tl mode with the following statements:

V%=l:CALL IBSRE(BRDO%,V%) (return)

CMD$=“TlX”:CALL IBWRT(M617%,CMD$) (return)

The instrument can now be addressed to talk to trigger a con-

version, and the resulting data displayed with the following

statements:

RD$=SPACE$(20):CALL IBRD(M617%,RD$) (return)

PRINT RD$ (return)

Each time the IBRD function is called, the instrument is ad-

dressed to talk, at which time it is triggered. When the con-

version is complete (360msec later), the reading is sent out

over the bus to the computer, which then displays the result-

ing data.

3.10.15 SRQ Mask IM) and Status Byte Format

The SRQ command controls which of a number of conditions

within the Model 617 will cause the instrument to request ser-

vice from the controller by asserting SRQ. Once an SRQ is

generated, the status byte can be checked to determine if the

Model 617 was the instrument that asserted SRQ, and, if so,

what conditions caused it to do so. Note that additional data

and error conditions can be checked by using the Ul and U2

commands, as described in paragraph 3.10.18.

3.28

The Model 617 can be programmed to generate an SRQ

under one or more of the following conditions:

1. If an overrange condition occurs.

2. When the data store memory is full (100 readings).

3. If a reading is completed.

4. When the instrument is ready to accept bus commands.

5. If an error occurs. The nature of the error can then be

determined with the Ul command, as described in

paragraph 3.10.18 (use Ul to restore SRQ after an error

occlm )

Upon power up, or after a DCL or SDC command is re-

ceived, SRQ is disabled.

SRQ Mask-The Model 617 uses an internal mask to deter-

mine which conditions will cause an SRQ to be generated.

Figure 3-10 shows the general format of this mask, which is

made up of eight bits. The SRQ has the same general format

as the status byte (described below) except for the fact that bit

6 is not used in the SRQ mask.

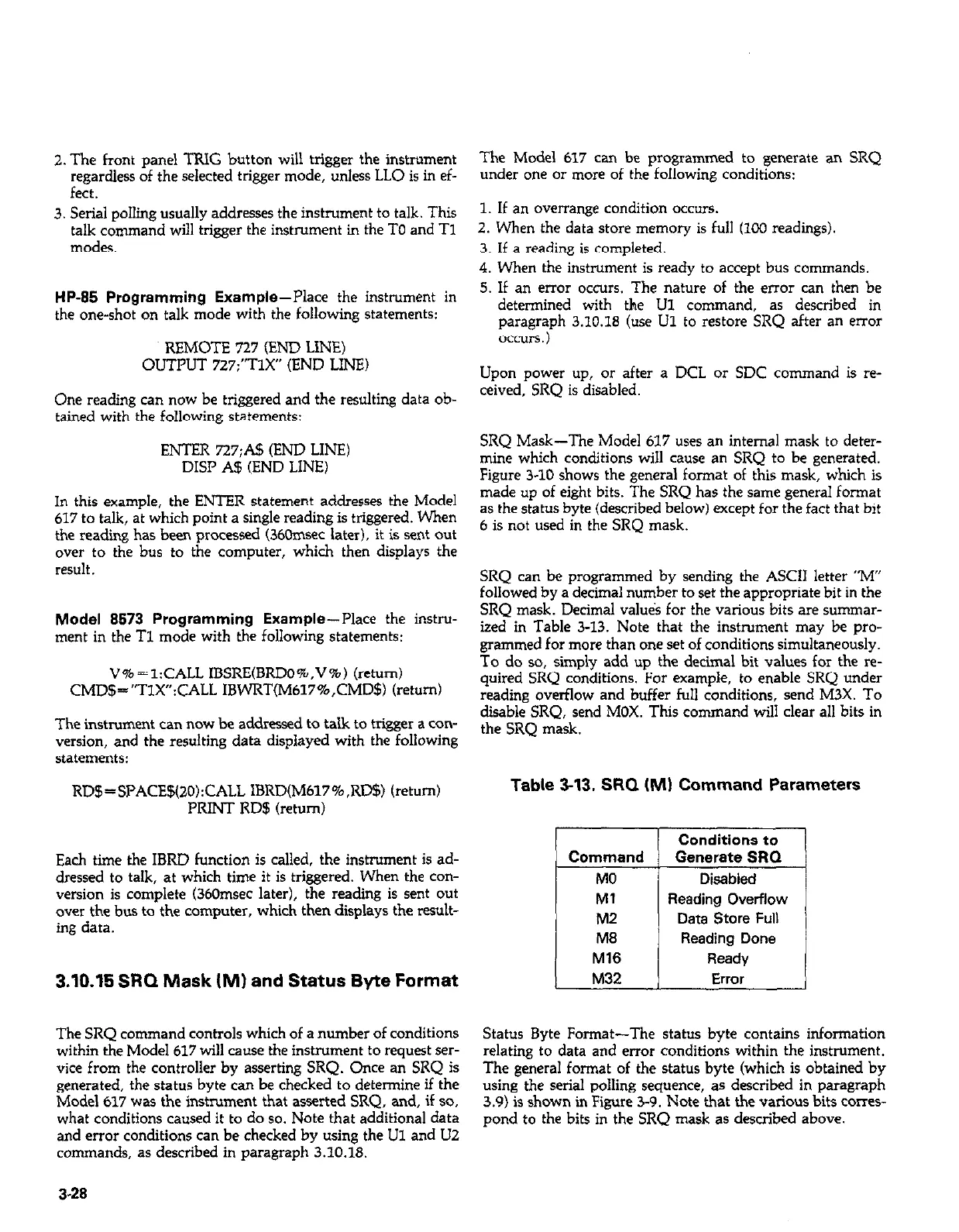

SRQ can be programmed by sending the ASCII letter “M”

followed by a decimal number to set the appropriate bit in the

SRQ mask. Decimal valu&s for the various bits are sununar-

ized in Table 3-13. Note that the instrument may be pro-

grammed for more than one set of conditions simultaneously.

To do so, simply add up the decimal bit values for the re-

quired SRQ conditions. For example, to enable SRQ under

reading overflow and buffer full conditions, send M3X. To

disable SRQ, send MOX. This command will clear all bits in

the SRQ mask.

Table 3-13. SRQ (MI Command Parameters

T

Reading Overflow

Data Store Full

Status Byte Format-The status byte contains information

relating to data and error conditions within the instrument.

The general format of the status byte (which is obtained by

using the serial polling sequence, as described in paragraph

3.9) is shown in Figure 3-9. Note that the various bits cor~es-

pond to the bits in the SRQ mask as described above.

Loading...

Loading...