!

I= ROS BY 617

-I

lSTAT”S BYTE ONLY)

I= ERROR

IA

I

1 =REAOING

OVERFLOW

1 = DATA STORE

1= READY I= READING DONE

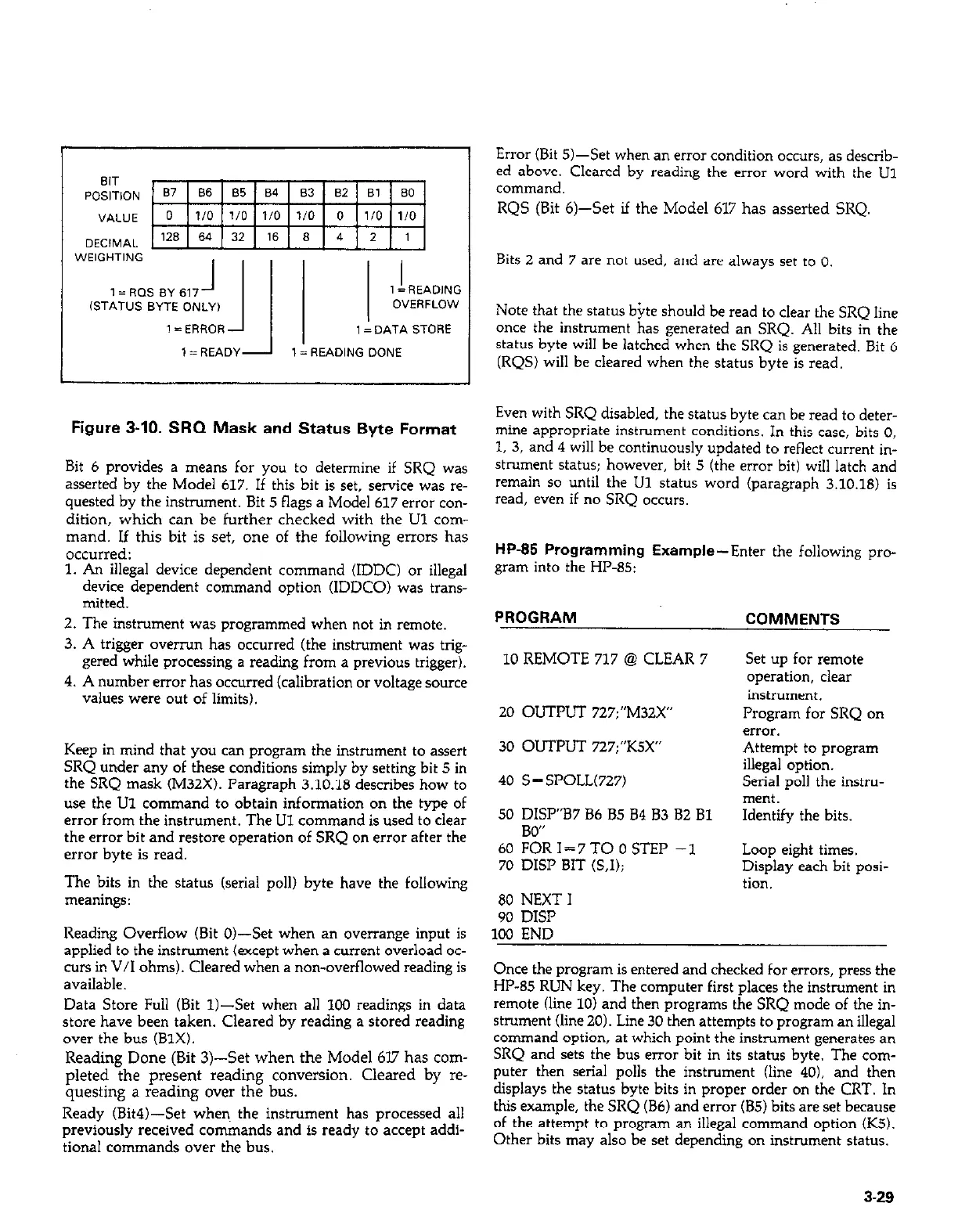

Figure 3-10. SRQ Mask and Status Byte Format

Bit 6 provides a means for you to determine if SRQ was

asserted by the Model 617. If this bit is set, service was re-

quested by the instrument. Bit 5 flags a Model 617 error con-

dition, which can be further checked with the Ul corn-

mand. If this bit is set, one of the following errors has

occurred:

1. An illegal device dependent command (IDDC) or illegal

device dependent command option (IDDCO) was trans-

mitted.

2. The instrument was programmed when not in remote.

3. A trigger overrun has occurred (the instrument was trig-

gered while processing a reading from a previous trigger).

4. A number error has occurred (calibration or voltage source

values were out of limits).

Keep in mind that you can program the instrument to assert

SRQ under any of these conditions simply by setting bit 5 in

the SRQ mask (M32X). Paragraph 3.10.18 describes how to

use the Ul command to obtain information on the type of

error from the instrument. The LJl command is used to clear

the error bit and restore operation of SRQ on error after the

error byte is read.

The bits in the status (serial poll) byte have the following

meanings:

Reading Overflow (Bit O&Set when an overrange input is

applied to the instrument (except when a current overload oc-

curs in V/I ohms). Cleared when a non-overflowed reading is

available.

Data Store Full (Bit 1)-&t when all 1OO readings in data

store have been taken. Cleared by reading a stored reading

over the bus (B1X).

Reading Done (Bit 3)--S& when the Model 6l7 has com-

pleted the present reading conversion. Cleared by re-

questing a reading over the bus.

Ready (Bit4)-Set when. the instrument has processed all

previously received commands and is ready to accept addi-

tional commands over the bus.

Error (Bit 5)-Set when an error condition occurs, as describ-

ed above. Cleared by reading the error word with the U1

command.

RQS (Bit 6)--S& if the Model 617 has asserted SRQ.

Bits 2 and 7 are not used, and are always set to 0.

Note that the status bite should be read to clear the SRQ line

once the instrument has generated an SRQ. All bits in the

status byte will be latched when the SRQ is generated. Bit 6

(RQS) will be cleared when the status byte is read.

Even with SRQ disabled, the status byte can be read to deter-

mine appropriate instrument conditions. In this case, bits 0,

1, 3, and 4 will be continuously updated to reflect current in-

strument status; however, bit 5 (the error bit) will latch and

remain so until the U1 status word (paragraph 3.10.18) is

read, even if no SRQ occurs.

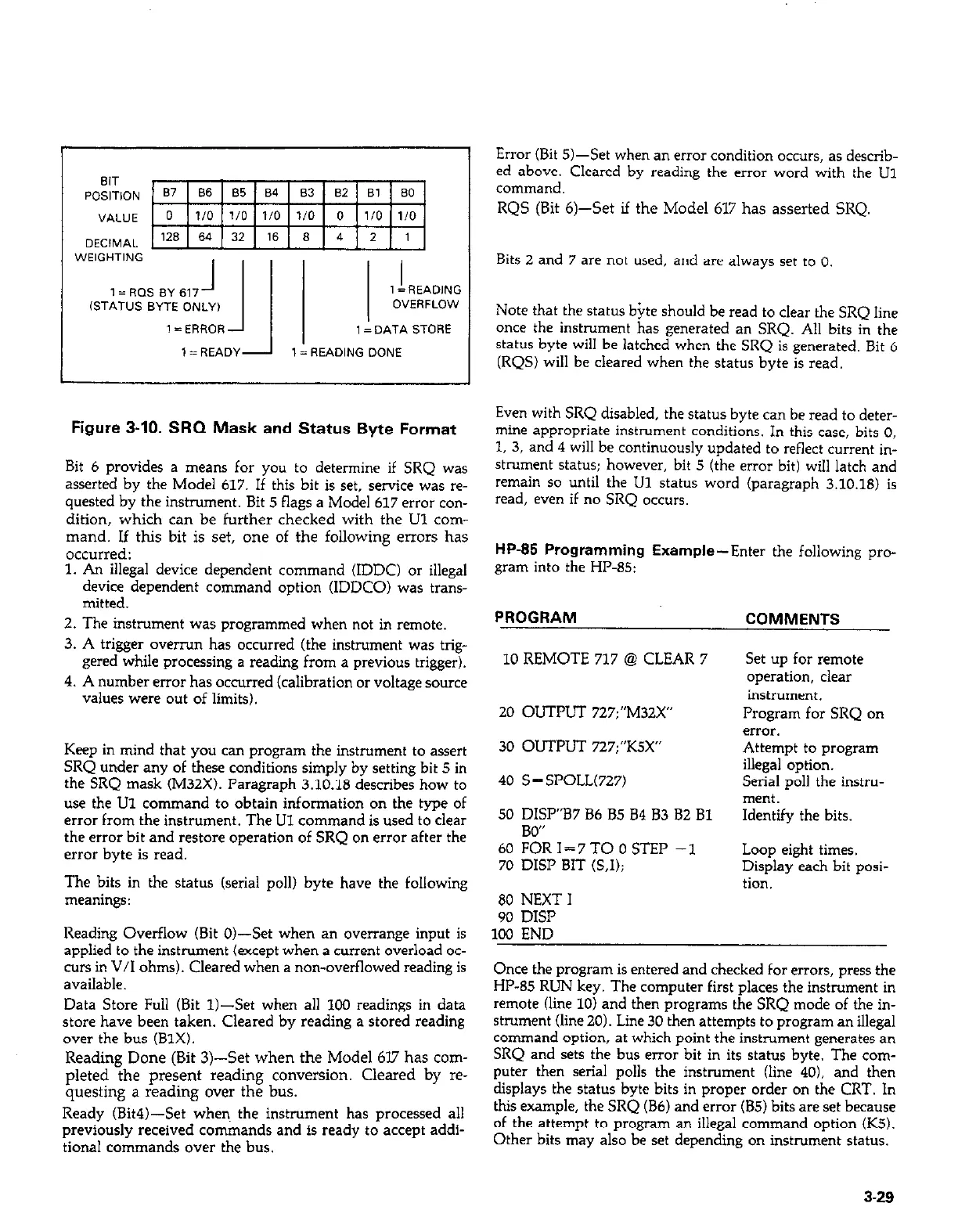

HP-85 Programming Example-Enter the following pro-

gram into the HP-85:

PROGRAM

COMMENTS

10 REMOTE 717 @ CLEAR 7

20 OUTPUT 727;“M32X”

30 OUTPUT 727;“KSX”

set up for remote

operation, clear

instrument.

Program for SRQ on

error.

Attempt to program

40 S = SPOLL(727)

illegal option.

Serial poll the instru-

ment.

50 DISP”B7 B6 85 84 83 B2 Bl

Identify the bits.

RW’

60 %R 1=7TO 0 STEP -1

70 DISP BIT (S.1):

80 NEXT I

90 DISP

100 END

Loop eight times.

Display each bit posi-

tion.

Once the program is entered and checked for errors, press the

HP-85 RUN key. The computer first places the instrument in

remote (line 10) and then programs the SRQ mode of the in-

strument (line 20). Line 30 then attempts to program an illegal

command option, at which point the instrument generates an

SRQ and sets the bus error bit in its status byte. The com-

puter then serial polls the instrument (line 40). and then

displays the status byte bits in proper order on the CRT. In

this example, the SRQ (B6) and error (B5) bits are set because

of the attempt to program an illegal command option (KS).

Other bits may also be set depending on instrument status.

3-29

Loading...

Loading...