EN

6. BASIC TROUBLESHOOTING

NOTE! The problems listed and the possible causes are not denitive, but serve to suggest some

standard and typical situations that may present during normal environmental use when using

the MIG/MAG process with KempArc Pulse.

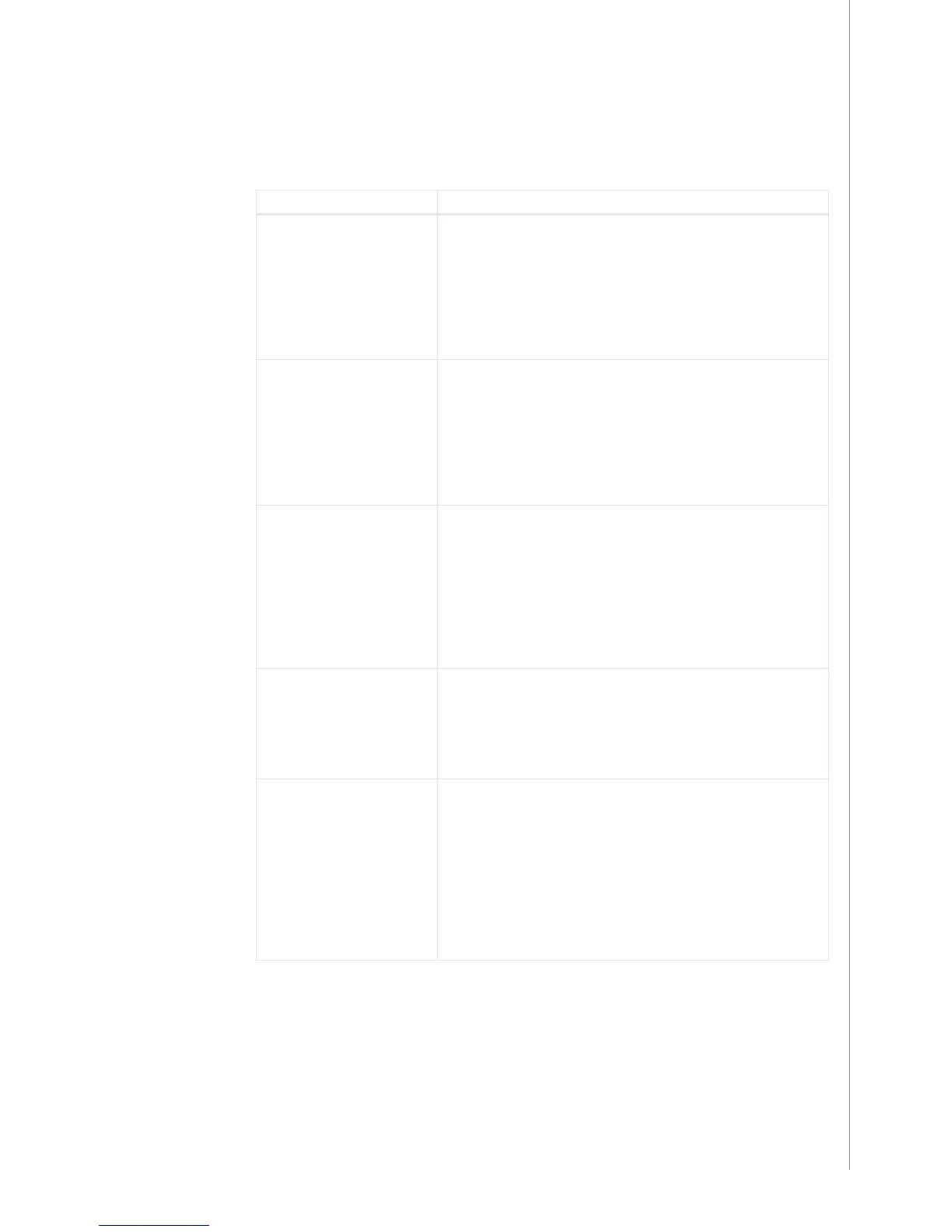

Problem Check the following

Machine won’t work? • Check mains plug is connected

• Check mains power distribution is switched on

• Check the mains fuse and or circuit breaker

• Check power source 0/I switch is ON

• Check interconnection cable set and connectors between the power source and

wire feed unit are correctly fastened. See the manual schematic

• Check earth return lead is connected

• Check function panels are switched on – Orange buttons top left, long press.

Dirty, poor quality weld? • Check shielding gas supply

• Check and set gas ow rate

• Check gas type for application

• Check gun/electrode polarity. Example: Fe solid ller wire: Earth return should be

connected to the – pole, wire feed unit to the + pole connector

• Check correct welding curve selected

• Check correct Channel (job) number selected on KF 62 function panel

• Check power supply – Phase down?

Variable welding performance? • Check wire feed mechanism is correctly adjusted

• Check correct drive rolls are tted

• Check wire spool overrun tension is correctly adjusted

• Check gun liner is not blocked. Replace if necessary

• Check correct gun liner is tted for the ller wire size and type

• Check contact tip for size, type and wear

• Check gun is not over heating in application

• Check cable connections and earth return clamp

• Check welding parametre settings.

Filler wire won’t feed? • Check wire feed mechanism. Pressure arms are closed? Close and adjust

• Check welding gun switch function.

• Check euro gun collar is correctly fastened to euro block

• Check gun liner is not blocked

• Check contact tip, size, type, wear

• Check and try alternative gun.

High spatter volume? • Check welding parametre values

• Check inductance/Dynamics values

• •Checkcablecompensationvalueiflongcablesaretted

• Check gas type and ow

• Check welding polarity – cable connections

• Check ller material selection

• Check correct welding curve selected

• Check correct Channel (job) number selection

• Check ller wire delivery system

• Check power supply – 3 x phase present?

NOTE! Many of these checks may be carried out by the operator. However certain checks relating to

mains power must be completed by an authorised trained electrician.

25

KempArc Pulse 350, 450 / © Kemppi Oy / 1044

Loading...

Loading...