11. PARAMETERS TABLES

All parameters tables with database entered via access key are shown below. Depending on flue draught, the

parameters in red must be checked and eventually modified upon Commissioning.

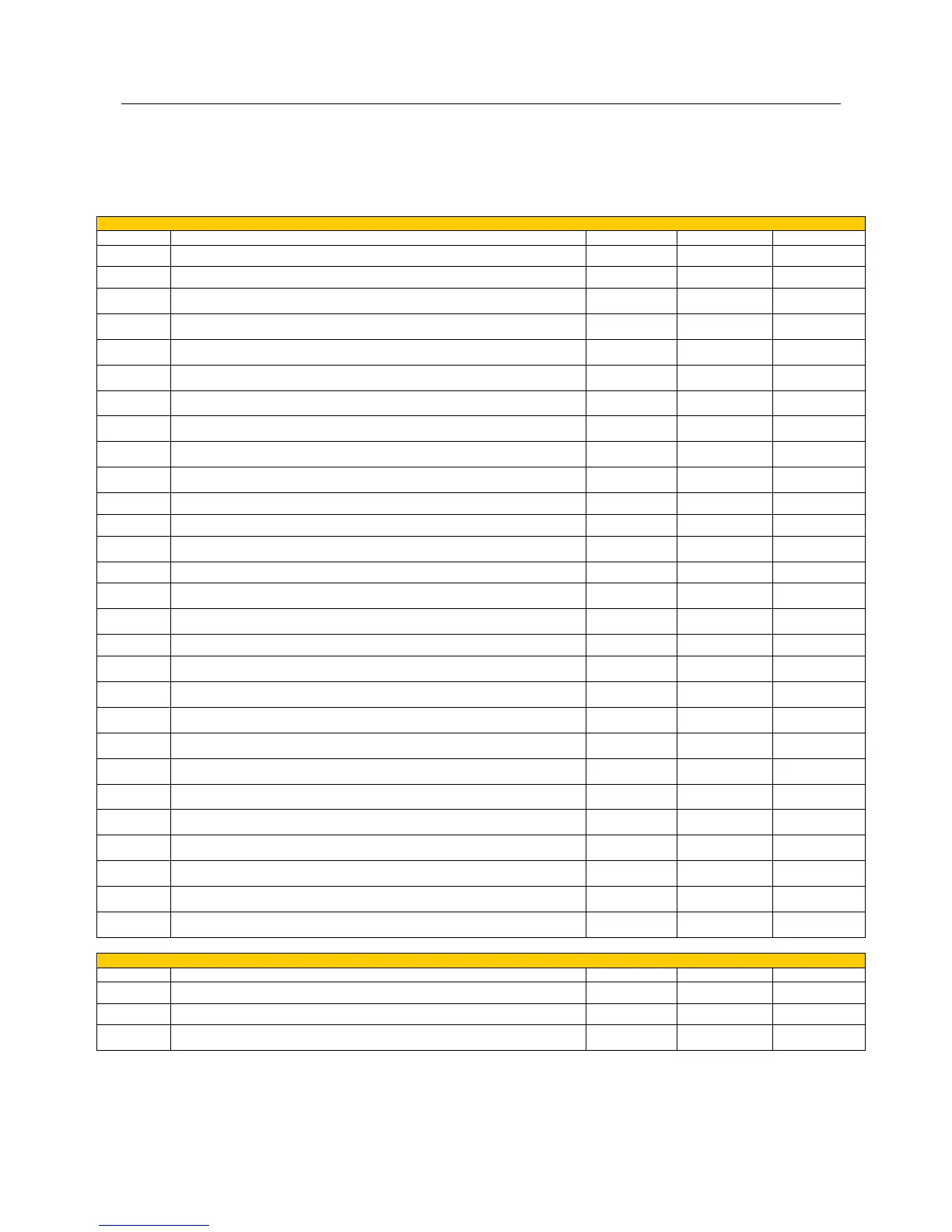

DIVA FIRMWARE (DV130710_3.ENC) GENERAL PARAMETERS ACCESS KEY A9

Ignition cycle maximum time “LOAD PELL”

Time interval between the two brazier cleaning operations

Screw feed motor reducer ON time in ignition phase “LOAD PELL”

Screw feed motor reducer ON time in start phase “FIRE ON”

Screw feed motor reducer ON time in power 1 work phase

Screw feed motor reducer ON time in power 2 work phase

Screw feed motor reducer ON time in power 3 work phase

Screw feed motor reducer ON time in power 4 work phase

Screw feed motor reducer ON time in power 5 work phase

Temperature differential on “SET H2O” for switch-off/on

Flue gas minimum temperature to consider equipment on

Flue gas maximum temperature accepted “ECO FUMI”

Pump activation threshold

Flue gas intake device speed during ignition phase “LOAD PELL”

Flue gas intake device speed during start phase “FIRE ON”

Flue gas intake speed in power 1 work phase

Flue gas intake speed in power 2 work phase

Flue gas intake speed in power 3 work phase

Flue gas intake speed in power 4 work phase

Flue gas intake speed in power 5 work phase

Time after which equipment switches off if it remains in “ECO H2O”

Brazier cleaning duration

Flue gas intake device switch-off threshold (in stand-by switch-off phase)

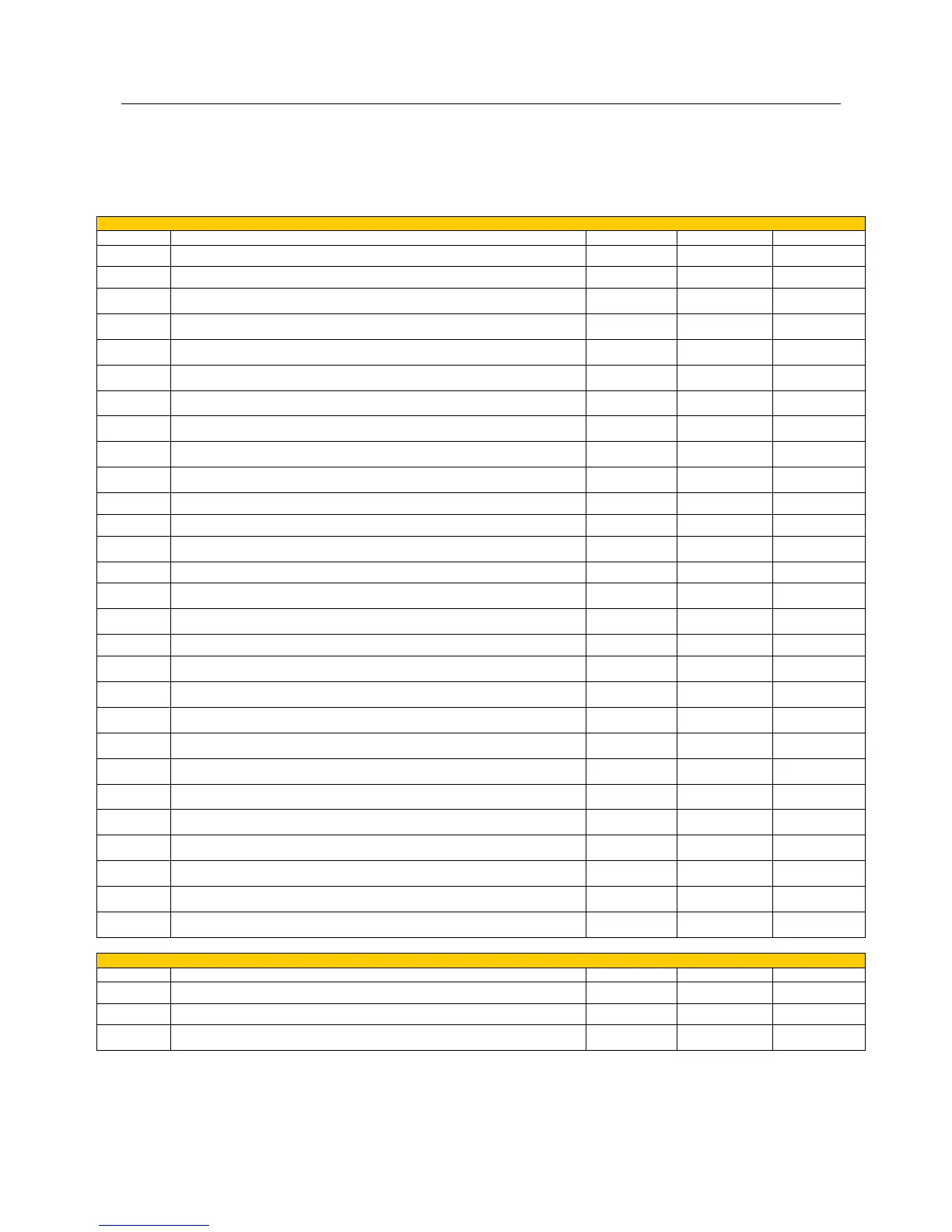

DIVA FIRMWARE (DV130710_3.ENC) PRE-LOAD PARAMETERS ACCESS KEY B9

Screw feed motor reducer ON time in pre-load phase

Stand-by time after pre-load phase

Flue gas intake device speed in pre-load phase

Loading...

Loading...