Wall Mounted Cabinets

The Graham Collection

®

Overview

Wall Hung

Components

Credenzas &

Extender Tops

Desktop Towers &

Bridge Overheads

Hinged Modesty

& Support Corners Desks

Bridges &

ReturnsPeninsulasAccessories

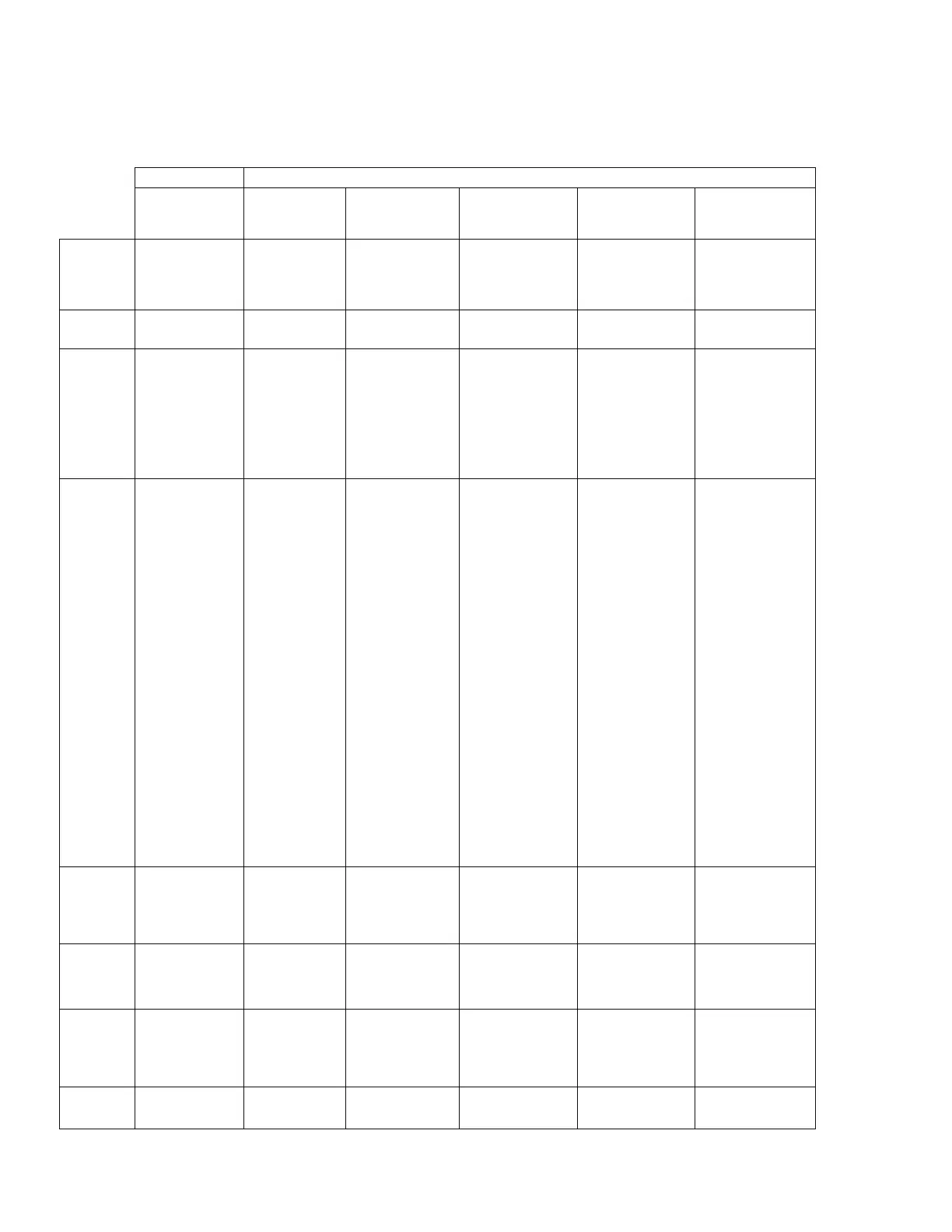

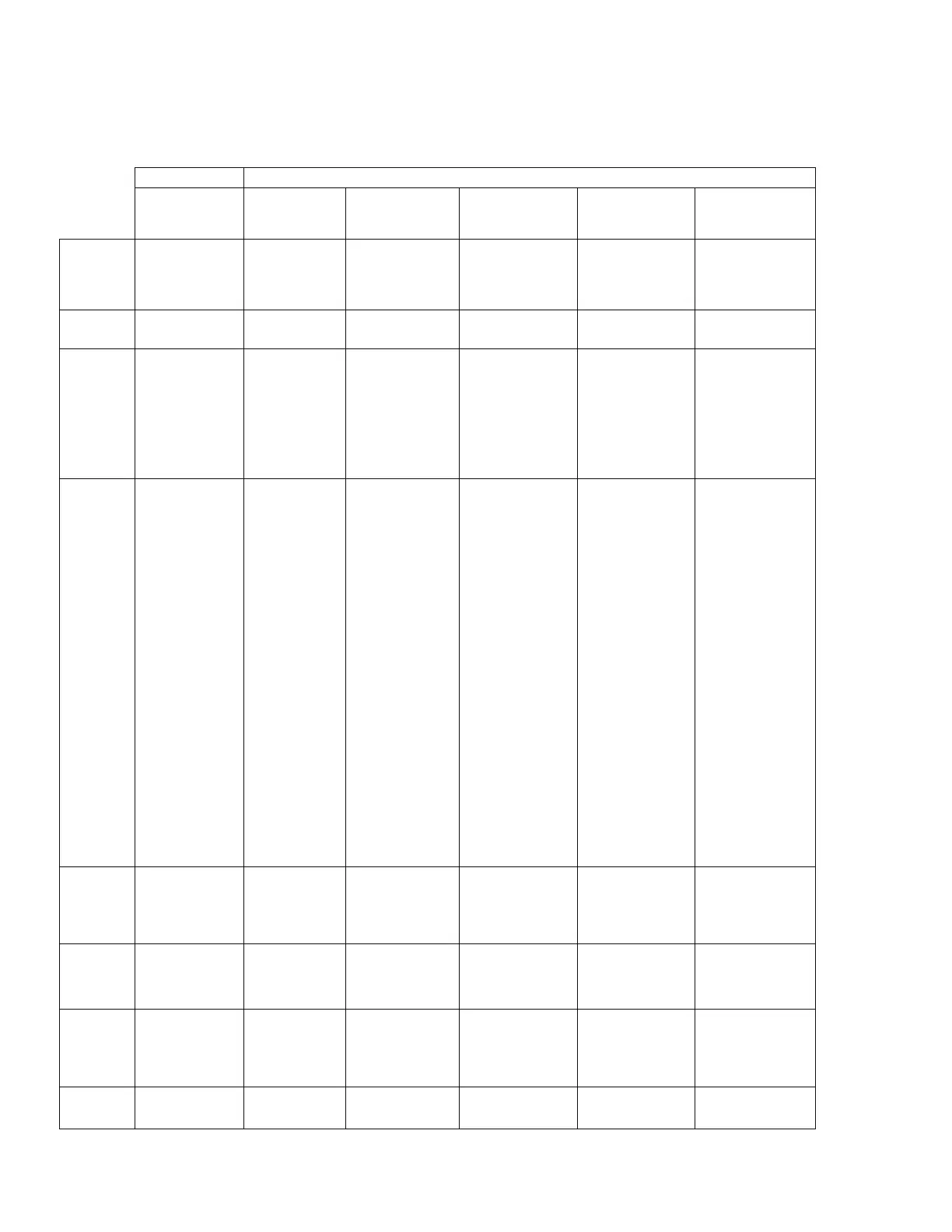

NEW

CONSTRUCTION

Cinder Block or

Poured Concrete

Masonry Wall

Wood Stud Wall, the

studs being

FULL HEIGHT to the

roof/floor above

Wood Stud Wall,

the studs being only

Ceiling Height

Steel Stud Wall,

the studs being

FULL HEIGHT to the

roof/floor above

Steel Stud Wall,

the studs being only

Ceiling Height

Stud

Specification

Wood studs, grade

#2 or better, 3 1/2"

minimum width, OR

Metal studs, minimum

25 gage thickness, 3

5/8" minimum width

The wall must be a

minimum of 6" thick,

and must be full

height to the roof/

floor structure above

Wood studs must be

Grade #2, or better,

3 1/2" minimum width

Wood studs must be

Grade #2, or better,

3 1/2" minimum width

Metal studs must be

minimum 25 gage

thickness, 3 5/8"

minimum width

Metal studs must be

minimum 25 gage

thickness, 3 5/8"

minimum width

Stud

Centers

Metal and wood studs

must be spaced at

16" c/c maximum

N/A Wood studs must

be spaced at 16" c/c

maximum

Wood studs must be

spaced at 16"" c/c

maximum"

Metal studs must be

spaced at 16" c/c

maximum

Metal studs must be

spaced at 16" c/c

maximum

Stud

Height

Metal and wood studs

must extend upwards,

and be securely

attached to the roof/

floor structure above

Wood studs must be

braced above the ceiling,

and be securely attached

to the roof/floor structure

above

Affix #2 grade 'cap'

across the top of the

studs, then place diagonal

studs from the top cap up

to underside of the roof/

floor structure above

Metal studs must be

braced above the ceiling,

and be securely attached

to the roof/floor structure

above

Affix metal bracing 'cap'

across the top of the

studs, then place diagonal

studs from the top cap up

to underside of the roof /

floor structure above

Mounting

the Knoll

Supplied

Cleat,

Bracket,

Frame, etc*

Insert a 2" X 6" wood

block, #2 grade or

better, [or a Danback

TM

flexible wood backing

system] horizontally

between each of the

studs to accommodate

the full width of the

cabinet, and beyond

to the next stud.

Fasten the wood block

to each stud using

three screws at the

ends of each block.

(Fasten the Danback™

as directed by the

manufacturer)

Fasten the Knoll

supplied wall mounting

cleat, bracket, frame,

etc directly to each

wood block every 6"

For wall mounting

structures that have a

rectangular frame-like

configuration: fasten

the top horizontal

element of the frame

to the wood blocking

every 6", and fasten

the lower horizontal

element to each

wall stud, using one

fastener per stud.

Fasten the Knoll

supplied cabinet

wall mounting cleat,

bracket, frame,

etc. directly to the

masonry wall every 6"

For wall mounting

structures that have a

rectangular frame-like

configuration: fasten

the top horizontal

element of the frame

to the wall every 6",

and fasten the lower

horizontal element to

the wall every 16"

In the desired location

of the cabinet mounting

rail, remove an 8" high

section of drywall the

width of the cabinet,

and beyond to the next

stud.

Insert a 2" X 6" wood

block, #2 grade or

better, horizontally

between each of the

exposed studs.

Fasten the wood block

to each stud using three

screws at the ends of

each block.

Replace the drywall and

repair as desired.

Fasten the Knoll supplied

wall mounting cleat, rail,

frame, etc directly to the

wood block every 6"

For wall mounting

structures that have a

rectangular frame-like

configuration: fasten the

top horizontal element

of the frame to the

wood blocking every

6", and fasten the lower

horizontal element to

each wall stud, using

one fastener per stud.

In the desired location

of the cabinet mounting

rail, remove an 8" high

section of drywall the

width of the cabinet,

and beyond to the next

stud.

Insert a 2" X 6" wood

block, #2 grade or better,

horizontally between

each of the exposed

studs.

Fasten the wood block

to each stud using three

screws at the ends of

each block.

Replace the drywall and

repair as desired.

Fasten the Knoll supplied

wall mounting cleat, rail,

frame, etc directly to the

wood block every 6"

For wall mounting

structures that have a

rectangular frame-like

configuration: fasten the

top horizontal element

of the frame to the

wood blocking every

6", and fasten the lower

horizontal element to

each wall stud, using one

fastener per stud.

In the desired location of

the cabinet mounting rail,

remove an 8" high section

of drywall the width of the

cabinet, and beyond to

the next stud.

Insert a 2" X 6" wood

block, #2 grade or better,

[or a Danback™ flexible

wood backing system]

horizontally between each

of the exposed studs.

Fasten the wood block

to each stud using three

screws at the ends of

each block.

Replace the drywall and

repair as desired.

Fasten the Knoll supplied

wall mounting cleat, rail,

frame, etc directly to the

wood block every 6"

For wall mounting

structures that have a

rectangular frame-like

configuration: fasten the

top horizontal element of

the frame to the wood

blocking every 6", and

fasten the lower horizontal

element to each wall

stud, using one fastener

per stud.

In the desired location of

the cabinet mounting rail,

remove an 8" high section

of drywall the width of the

cabinet, and beyond to

the next stud.

Insert a 2" X 6" wood

block, #2 grade or better,

[or a Danback™ flexible

wood backing system]

horizontally between each

of the exposed studs.

Fasten the wood block

to each stud using three

screws at the ends of

each block.

Replace the drywall and

repair as desired.

Fasten the Knoll supplied

wall mounting cleat, rail,

frame, etc directly to the

wood block every 6"

For wall mounting

structures that have a

rectangular frame-like

configuration: fasten the

top horizontal element of

the frame to the wood

blocking every 6", and

fasten the lower horizontal

element to each wall

stud, using one fastener

per stud.

Fasten

the Knoll

supplied wall

cleat with...

#10 x 2 1/2" Grabber

Woodys Screws

or equiv. @ 6" c/c,

screwed directly into

the wood blocking

3/16" x 3 1/2" Ta pcon

Masonry Screws or

equiv. @ 6" c/c with

1-1/4" embedment,

screwed directly into

the masonry wall

#10 x 2 1/2" Grabber

Woodys Screws

or equiv. @ 6" c/c,

screwed directly into the

wood blocking

#10 x 2 1/2" Grabber

Woodys Screws or

equiv. @ 6" c/c, screwed

directly into the wood

blocking

#10 x 2 1/2" Grabber

Woodys Screws or

equiv. @ 6" c/c, screwed

directly into the wood

blocking

#10 x 2 1/2" Grabber

Woodys Screws or equiv.

@ 6" c/c, screwed directly

into the wood blocking

EXISTING CONSTRUCTION

Wall Mounting of Knoll Products

Overview

Additional

Required

Bracing

No No No 2 x 4's across the

top of the studs, with

diagonals attached

to underside of roof /

floor structure above

No Track across the top of

the studs with diagonal

studs attached to

underside of roof /

floor structure above

END

CONDITION

(only if cleat

extends

more than 6"

past stud)

Danback™ flexible

woodbacking system

or equivalent

N/AToggler Snapskru

drywall anchors

with #8 x 2" screw

@ 4-1/2" c/c with

2-1/2" end distance

Toggler Snapskru

drywall anchors

with #8 x 2"screw

@ 4-1/2" c/c with

2-1/2" end distance

Toggler Snapskru

drywall anchors

with #8 x 2" screw

@ 4-1/2" c/c with

2-1/2" end distance

Toggler Snapskru

drywall anchors

with #8 x 2" screw

@ 4-1/2" c/c with

2-1/2" end distance

Additional

Required

Construction

Danback™ flexible

wood backing system

or equivalent

No No No No No

Loading...

Loading...