Fabric Intermediate Screens - Partial Depth

for Use with Tops with Hinged Access

Pattern Numbers Represented:

Fabric Intermediate Screens, YPSI__F

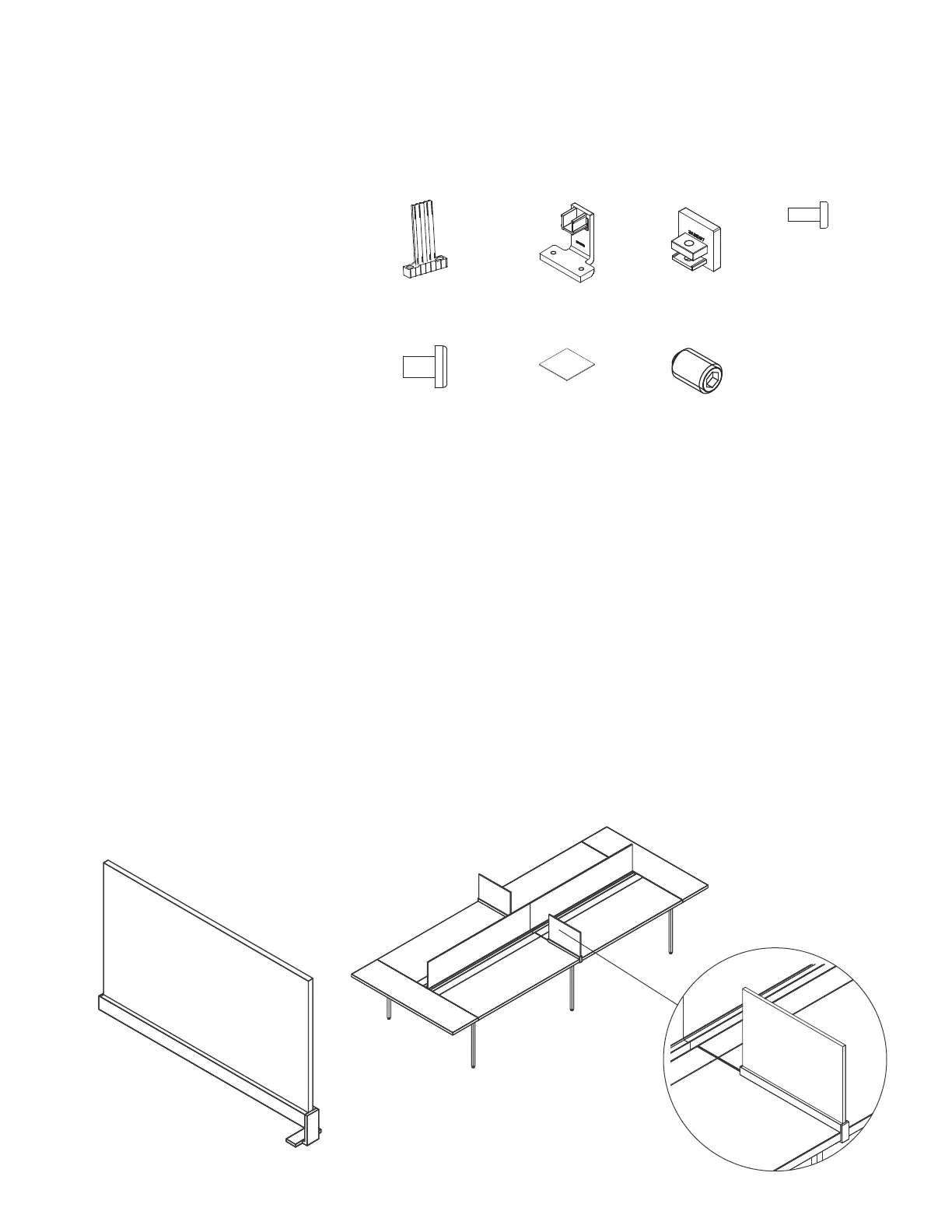

Parts List:

Bayonet Mount Bracket (A)

Upholstered Intermediate Screen Rail Clamp (B)

Upholstered Intermediate Screen Rail End Cap (C)

5

/

16

-18 x ¾" Machine Screw (D)

¼ - 20 x

3

/

8

" Black Oxide Machine Screw (E)

Non-Skid Pad (F)

¼ - 20 x

3

/

8

" Set Screw (G)

Screen Bottom Extrusion

Screen

Tools Needed:

Drill

Phillips #2 and #3 bits

1

/

8

" Allen Key

STEPS

1. Insert (2) bayonet mount brackets (A) into

the top of the screen bottom extrusion so

that the holes in the brackets align with

the two sets of holes in the extrusion.

2. Insert (4)

5

/

16

-18 x ¾" machine screws (D)

beneath the extrusion and firmly attach the (2)

bayonet mount brackets (A) to the extrusion.

3. Insert (1) upholstered intermediate

screen rail end cap (C) into one end

of the bottom screen extrusion.

4. Insert (1) hex head set screw (G) into the end cap

(C) and secure it to the bottom screen extrusion.

5. Peel the protective paper from one side

of the non-skid pad (F) to expose one

of the adhesive sides.

6. Affix the non-skid pad (F) to the underside

of the bottom screen extrusion close to the

end cap (C) that has just been attached.

NOTE: DO NOT REMOVE THE OTHER SIDE

OF THE PROTECTIVE PAPER AT THIS POINT.

7. Determine the desired screen position along

the width of the table, and position the screen

extrusion on the worksurface accordingly.

8. Hook (1) upholstered intermediate screen rail

clamp (B) to the front edge of the worksurface

so that the clamp’s u-channel is above the

worksurface and the two screw holes are below

the worksurface. Slide the open end of the

bottom screen extrusion onto the u-channel

portion to temporarily support the bracket.

9. Lifting the free end of the screen assembly

slightly, carefully peel the protective paper

from the other side of the non-skid pad

(F), then firmly press the screen assembly

downward to adhere the free end of the

bottom screen extrusion to the worksurface.

10. Insert (2) ¼ - 20 x

3

/

8

" black oxide machine

screws (E) into the holes under the rail clamp

(B). Hold the U-channel portion of the rail

clamp (B) firmly against the side of the screen

bottom extrusion and tighten the screws

against the bottom of the worksurface.

NOTE:The ¼ - 20 x

3

/

8

" black oxide machine

screws (E) are to be treated as set screws and

will create the tight connection between the

screen bottom extrusion and the worksurface.

The rail clamp (B) must be seated firmly within

the side of the bottom extrusion, but should not

be pressed tight against the bottom of the

worksurface. A space will remain between the

rail clamp and the bottom of the worksurface.

11. Position the openings in the underside

of the screen over the bayonet mount

brackets (A) and push the screen down

until the screen is firmly seated.

(A) 3AB408200 (B) 3AB1206* (C) 3AB1207* (D) 7060440

(E) 7019440 (F) 3AB419700 (G) 4A2200740

Intermediate Screens

Planning and Specification Guidelines

Antenna Workspaces

142

Intermediate Screens

Planning and Specification Guidelines

Antenna Workspaces

142

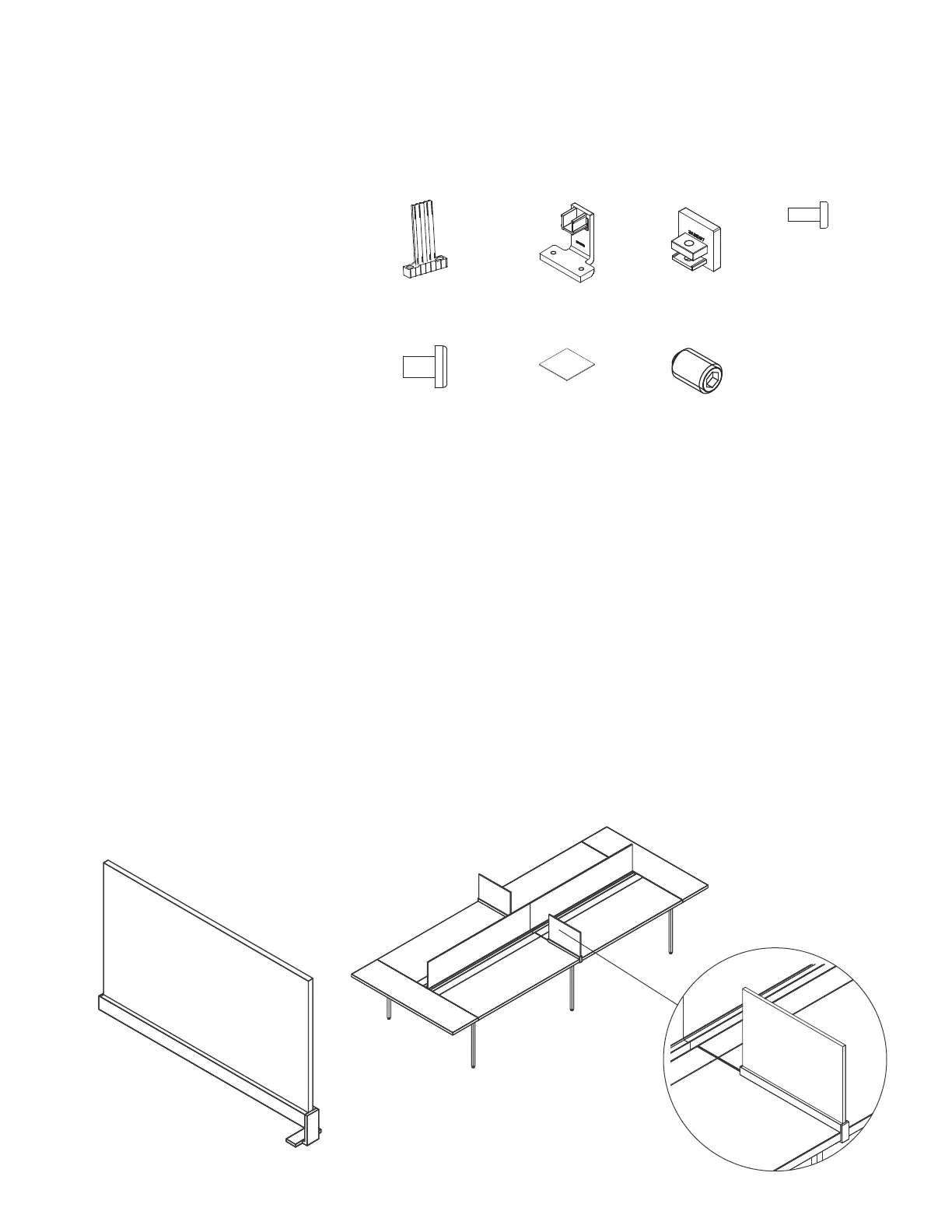

Partial Depth Intermediate Screen

for Use with Hinged Access Tops

Big Table with Hinged Access Tops and

Partial Depth Intermediate Screens

Loading...

Loading...