10.13

Section 10

Reassembly

10

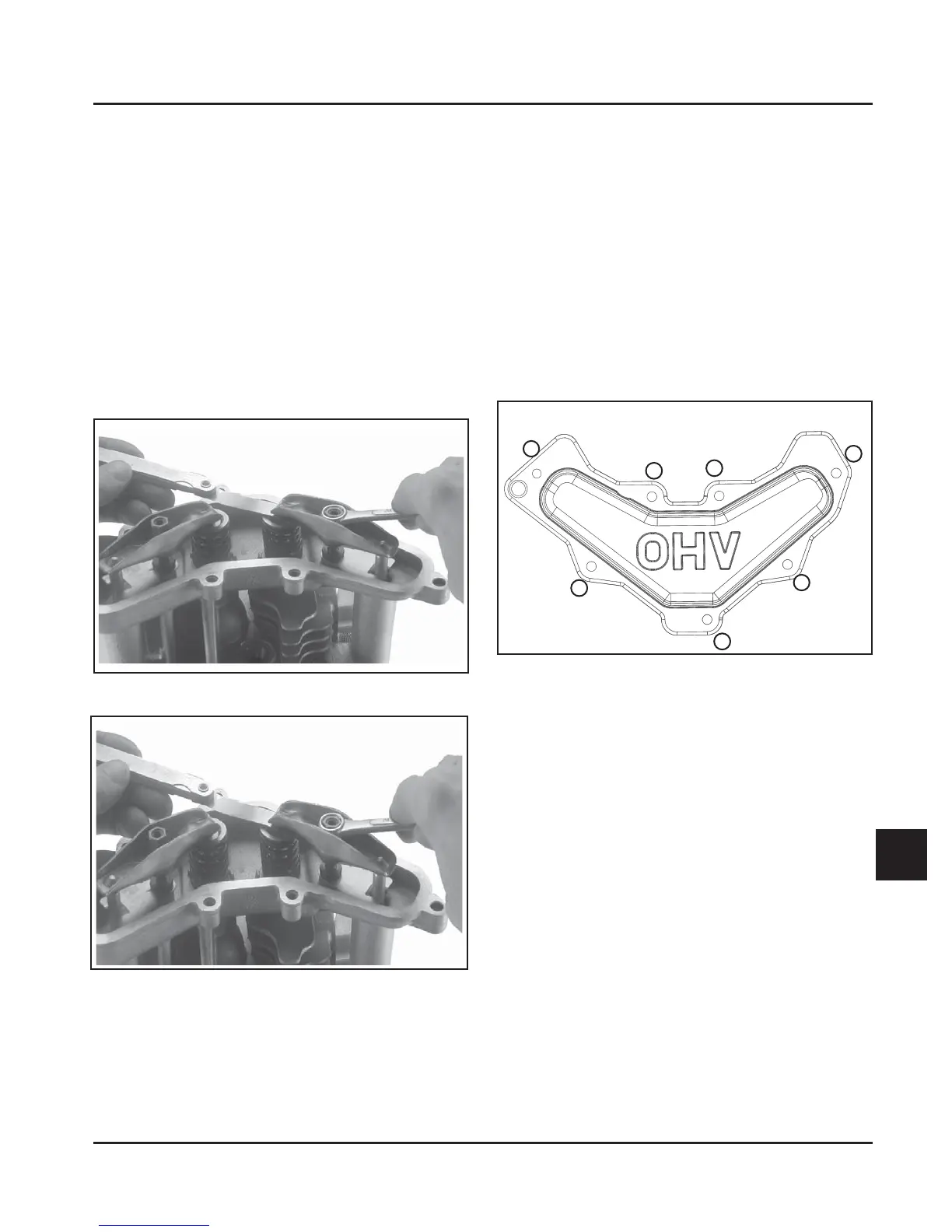

4. With the engine at TDC of the compression

stroke, insert the correct size flat feeler gauge

(see below) between the appropriate valve stem

and rocker arm. Tighten the adjustment nut

with a wrench until a slight drag is felt on the

feeler gauge. Hold the nut in that position and

torque the set screw (T15 Torx drive) to 5.5 N·m

(50 in. lb.). To prevent damage to the nut, torque

the Torx screw only. Perform the adjustment

procedure on the other valve. See Figures 10-44

and 10-45.

Valve Clearance Specifications:

Intake Valve 0.127 mm (0.005 in.)

Exhaust Valve 0.178 mm (0.007 in.)

Figure 10-44. Adjusting Valve Clearance (Lash).

Figure 10-45. Locking Adjustment Nut Set Screw.

Install Valve Cover

1. Make sure the sealing surfaces of the valve cover

and cylinder head are clean, and free of any nicks

or burrs.

2. Install a new valve cover gasket, followed by the

valve cover. Position any brackets that mount

on the valve cover and start the seven mounting

screws.

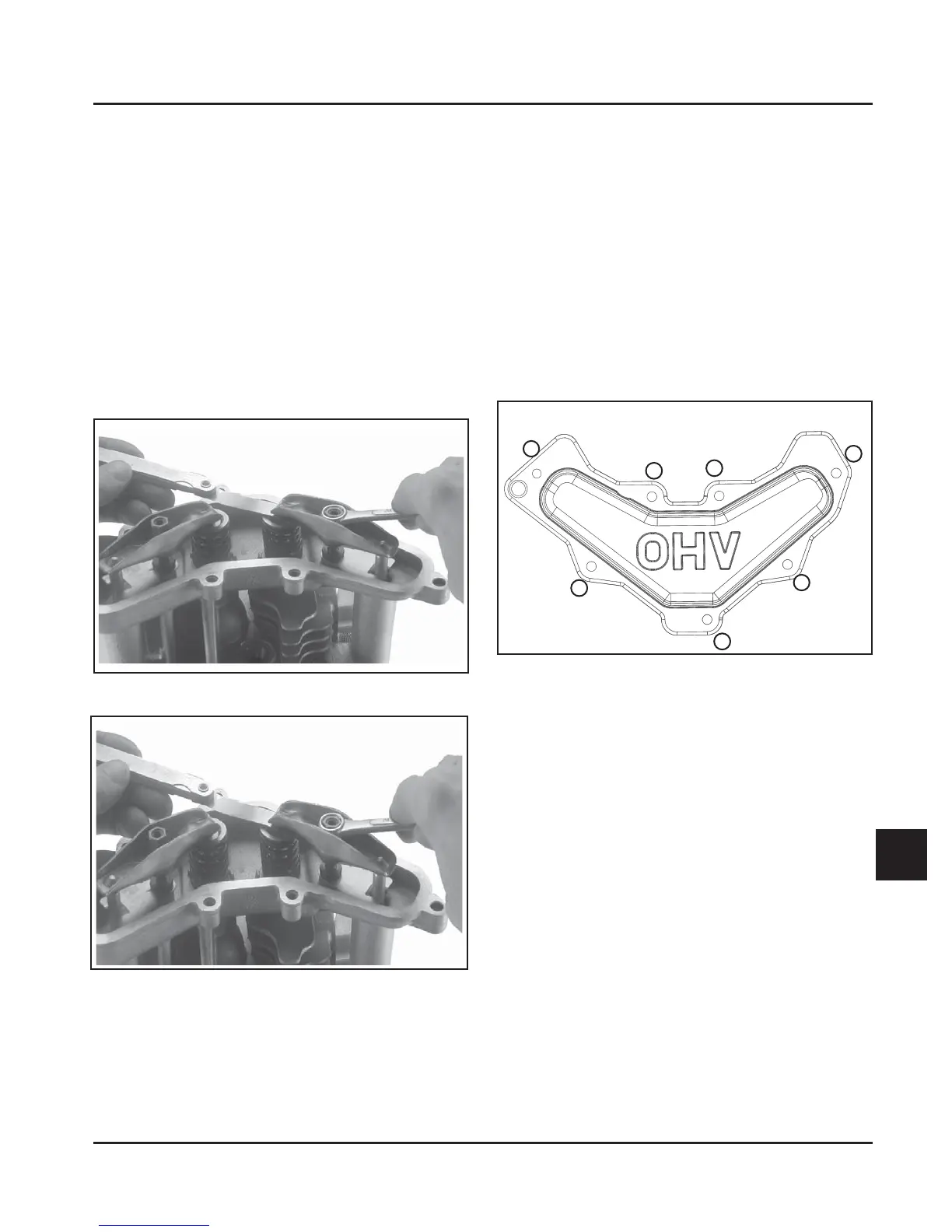

3. Torque the valve cover screws to 11.0 N·m

(95 in. lb.) into new, as-cast holes, or 7.5 N·m

(65 in. lb.) into used holes, using the sequence

shown in Figure 10-46.

7

5

2

3

4

1

6

Figure 10-46. Valve Cover Fastener Torque

Sequence.

Loading...

Loading...