Operation - Section 32 OM3223

Page 32-14 Operator Cab and Controls

Engine Cold Weather Start-

ing Aid (Optional)

Engine starting aid switch (8) is

spring-loaded to the OFF posi-

tion. Use only when the ambi-

ent temperature is below 10° C

(50° F). When the switch is

held in the ON position, ether is injected into the

engine intake manifold to aid engine starting in cold

weather. Move the engine starting aid switch to the

ON position while cranking engine, for three seconds

maximum, and then release engine starting aid. If the

engine does not start, wait at least fifteen seconds

before repeating the procedure. Refer to Operating

Instructions, for more specific operating details.

Rotating Beacon Light Switch

(Optional)

If the truck is equipped with the

optional rotating beacon light (9),

it will be activated by this rocker-

type switch when it is pressed

toward the ON position.

Heated Mirror Switch

(Optional)

If the truck is equipped with the

optional heated mirror (10), it will

be activated by this rocker-type

switch when it is pressed toward

the ON position.

Leakage Test Switch (Trolley Option Only)

Leakage current test switch (11) provides a means

for testing the current leakage relay circuitry of the

trolley system. This circuitry is designed to react to

short circuits between the trolley assist propulsion

system and the truck chassis.

This test must be performed before operating the

truck. Starting with the master control switch in the

DIESEL position, this leakage current test switch

must be held in the ON position for four seconds. If

the system is operating correctly, the trolley fault indi-

cator lamp (D7, Figure 3-7) will turn on. If the light

does not turn on, notify maintenance personnel. The

truck can still be operated in the diesel mode.

To reset, after the trolley fault indicator lamp turns on,

move the master control switch to the trolley position

for a minimum of one second, and then back to the

DIESEL position.

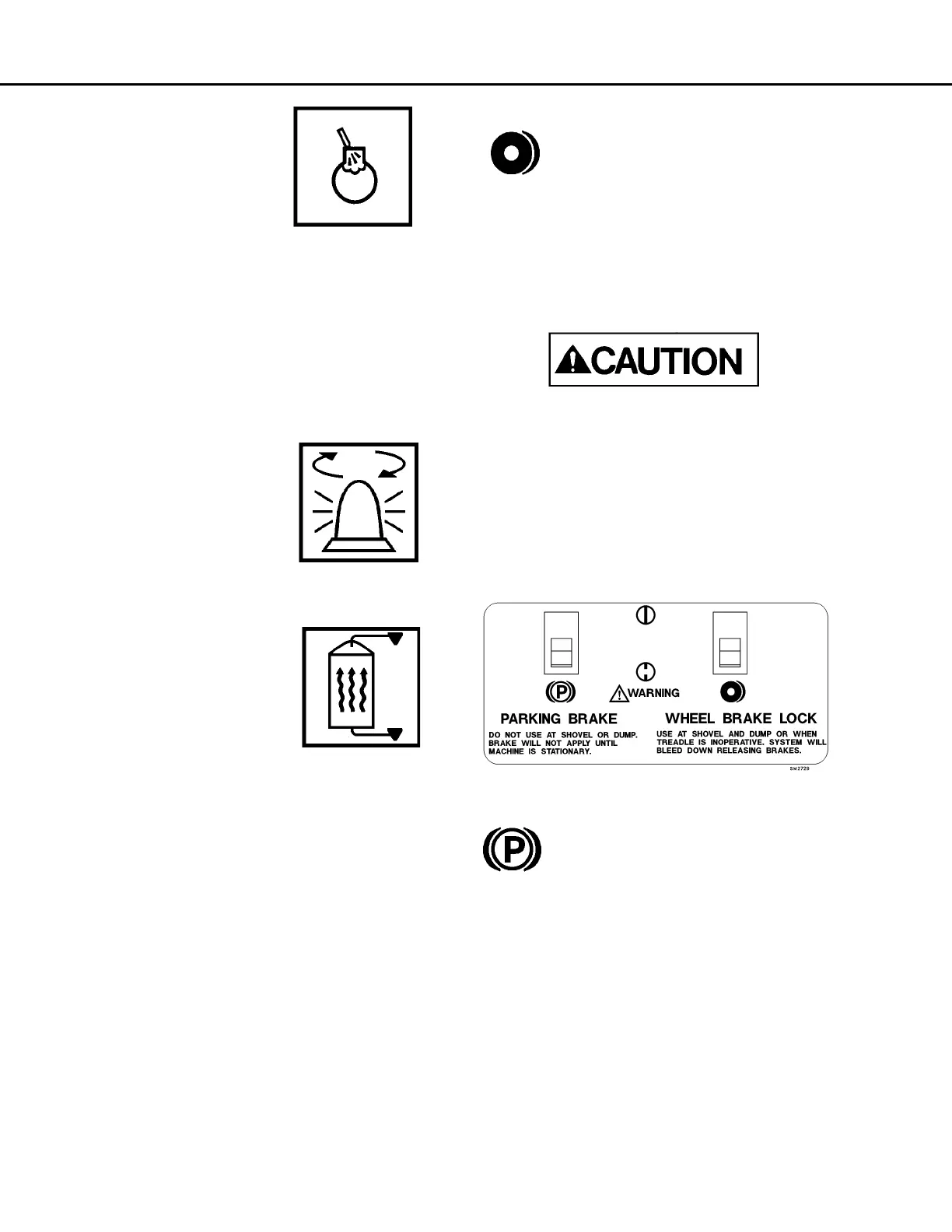

Wheel Brake Lock Control

Wheel brake lock (12) is to be used with

the engine on for dumping and loading

operations only. The brake lock switch

actuates the hydraulic brake system

which locks the rear wheel service brakes only.

When pulling into the shovel or dump area, stop the

truck using the foot-operated service brake pedal.

When the truck is completely stopped and in loading

position, apply the brake lock by pressing the rocker

switch toward the on symbol. To release, press the

rocker switch toward the off symbol.

Use at the shovel and dump only to hold the

truck in position.

Do not use this switch to stop the truck, unless

the service brake pedal is inoperative. Use of this

switch applies rear service brakes at full, unmod-

ulated pressure!

Do not use the brake lock for parking. With the

engine stopped, hydraulic pressure will bleed

down, allowing the brakes to release!

Parking Brake Control

The parking brake (13) is spring applied

and hydraulically released. It is designed

to hold a stationary truck when the

engine is turned off and key switch is

turned OFF. The truck must be completely stopped

before applying the parking brake, or damage may

occur to the parking brake. To apply the parking

brake, press the rocker switch toward the on symbol.

To release the parking brake, move parking brake

control (13) toward the off symbol. When the key

switch is ON and the parking brake switch is applied,

the parking brake indicator light (A3, Overhead

Panel) will be illuminated.

NOTE: Do not use the parking brake at the shovel or

dump. With the key switch ON and the engine on,

sudden shock caused by loading or dumping could

cause the system's motion sensor to release the park

brake.

Loading...

Loading...