33

KHF - SERIES A FAN COIL UNITS

INSTALLATION, OPERATION, AND MAINTENANCE MANUAL

TABLE F.5 – REPLACEMENT FUSE

TRANSFORMER FUSE

PART

NUMBER

MANUFACTURER

PART

NUMBER

30VA 2A PE-06-0000

Littelfuse 0235002.MXP

Bussmann BK/GMA-2-R

50VA 3A PE-06-0016

Littelfuse 0235003.MXP

Bussmann BK/GMA-3-R

TABLE F.6 – FIELD INSTALLED COMPONENT DESCRIPTIONS

NAME DESCRIPTION

Field-Provided

Float Switch

To install a oat switch, wire the oat switch leads into S1 and C on the crew

terminals. After wiring the oat switch, remove jumper JP2. The JP2 jumper

must be removed for the oat switch to operate correctly.

Note: If a oat switch was installed in the factory, the oat switch may be

connected through a factory-provided harnesses instead of wired to the

screw terminal.

Start/Stop

for the Fan

To start or stop the fan from an external controller, wire the leads for the

switch contacts that will be made or broken to R and G on the screw termi-

nals. After wiring the switch, remove jumper JP3.

Remote

3-Speed Switch

To add a remote 3-speed switch, wire the leads for the switch to G, H, M and L

on the screw terminals. After wiring the switch, remove jumper JP1.

Tools Required for Installation/Troubleshooting:

• Digital multimeter capable of measuring 30 volts AC

• Insulated 1/8” flat bladed screwdriver

• Fuse puller (optional)

• Mini hook test clips for multimeter (optional)

Fuse – A fuse is included on the secondary side of the

transformer to protect the transformer from incorrect

wiring of thermostat, controller, etc. that shorts the 24VAC

and COM. The fuse is a fast-acting glass body cylindrical

fuse (5x20mm). If tripped, replace the fuse by removing the

tripped fuse with fuse pullers and replace using one of the

below listed fuses.

Suggested fuse replacement information:

HEAT Output – The HEAT output connects to an electric heat

contactor or relay. This output represents the command

signal from the thermostat or controller on the W1 input.

The output is interlocked with the fan relays to ensure that

a fan speed is commanded when electric heat is requested.

DAMP Output – The DAMP output connects to a motorized

damper actuator used to control airflow from an external

source. This output provides 24VAC to energize the damper

actuator. This output is interlocked with the fan relays to

ensure that a fan speed is commanded before energizing

the damper actuator.

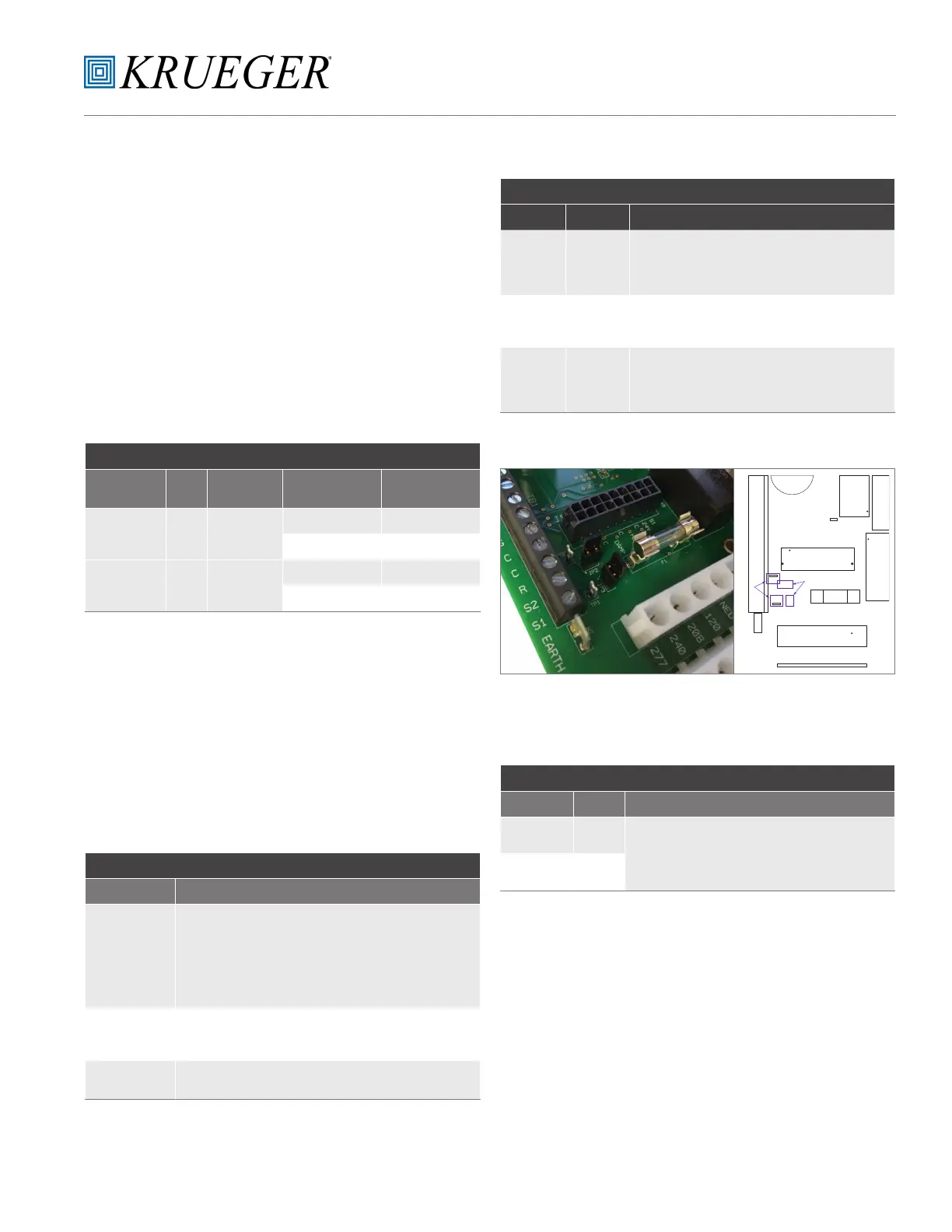

TABLE F.8 – TEST POINT DESCRIPTION

TEST POINT NAME DESCRIPTION

TP1 24VAC

These test points can be used to verify 24 VAC assuming incoming

voltage is within tolerance. They can be connected to with mini-

hook test clips for a digital multimeter. Test point locations for TP1

and TP2 can be seen in Figure F.3.

TP2 COM

TEST POINTS

JP2 and JP3 locations can be seen in Figure F.3.

TABLE F.7 – JUMPER DESCRIPTION

JUMPER NAME DESCRIPTION

JP1

Speed

Select

Jumper

This jumper is installed between 24V and HIGH when no three

speed switch is included (remote or unit mounted). The jumper will

be installed at the end of the harness connected to J1. If a three

speed switch is added later, JP1 must be removed.

JP2

Float

Switch

Jumper

This jumper is installed between S1 and C when a oat switch

is not installed. The jumper is removed when a oat switch is

installed.

JP3

Fan

Enable

Jumper

This jumper is installed between R and G/24V. The jumper is

removed when remote control of the fan motor is desired. In most

instances, JP3 will be installed (unless a thermostat or controller

is remotely controlling of the equipment).

JUMPERS

TP3

J1

F1

J2

TP2

JP2

TP1

JP3

W2

TEST

POINTS

JUMPERS

K1

TB1

Figure F.3: FRBii Jumpers and Test Points

Loading...

Loading...