7

KHF - SERIES A FAN COIL UNITS

INSTALLATION, OPERATION, AND MAINTENANCE MANUAL

If the valve package connection at the coil is made with a

union, the coil side of the union must be prevented from

twisting (“backed up”) during tightening to prevent damage

to the coil tubing. Over-tightening must be avoided to prevent

distorting the union seal surface and destroying the union.

Due to the diversity of valve packages for this product, install

the valve packages with no leaks or interference between

components during operation and maintenance. In the case

of field installed valves and piping, the chilled water valve

cluster (or metering device on DX units) should be installed in

such a way that any dripping or sweating is contained in the

auxiliary drain pan or other device. Valves and TXV’s should

be secured or supported to avoid damage to coil headers or

distributor tubes. All valves, pipes, and components must

be sufficiently supported to ensure structural integrity and

proper operation of the unit.

After the connections are completed, the system should

then be tested for leaks. Since some components are not

designed to hold pressure with a gas, hydronic systems

should be tested with water.

All water coils must be protected from freezing

after initial filling with water. Even if the system is

drained, unit coils may still hold enough water to

cause damage when exposed to temperatures

below freezing.

Refrigerant systems should be tested with dry nitrogen

rather than air to prevent the introduction of moisture

into the system. In the event that leaking or defective

components are discovered, the Sales Representative must

be notified BEFORE any repairs are attempted. All leaks

should be repaired before proceeding with the installation.

!

Caution

COOLING/HEATING MEDIUM CONNECTIONS

Toxic residues and loose particles resulting from

manufacturing and field piping techniques such

as joint compounds, soldering flux, and metal

shavings may be present in the unit and the piping

system. Not for use with domestic or potable water

systems.

Submittals and Product Catalogs detailing unit operation,

controls, and connections should be thoroughly reviewed

BEFORE beginning the connection of the various cooling

and/or heating mediums to the unit.

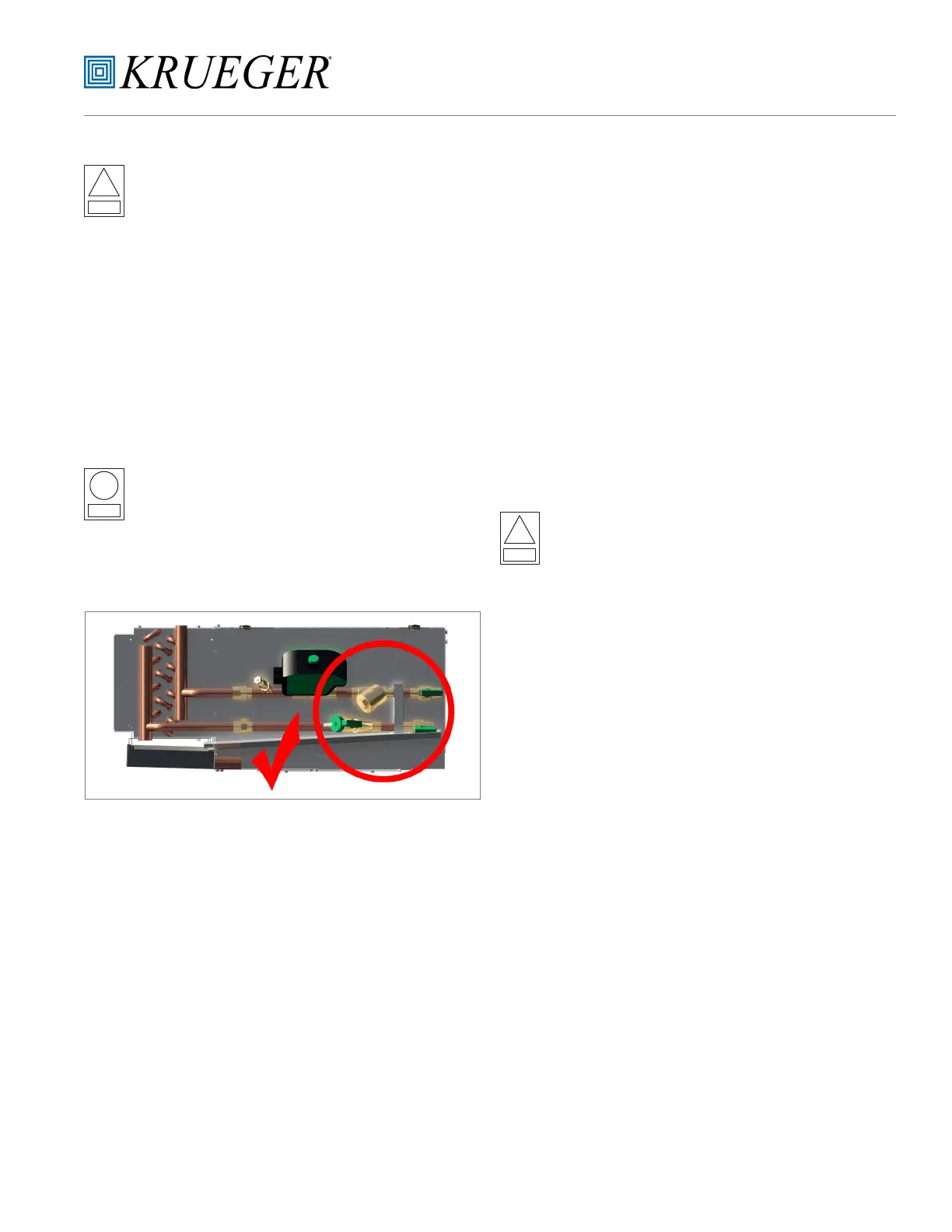

All accessory valve packages should be installed as required,

and all service valves should be checked for proper

operation. To prevent condensation accumulation and

runoff, chilled water valve packages must be insulated, or

preferably, utilize a factory-provided auxiliary drip tray.

Before brazing or sweating valve packages and their

components into place, it is critical to pre-check all

valve package clearances in relation to the auxiliary

drain pan. If the auxiliary drain pan cannot be

properly affixed to the auxiliary drain pan support

bracket, adjust valve package component angles

until proper clearance is achieved.

!

Caution

!

Note

If coil and valve package connections are to be made with

“sweat” or solder joint, care should be taken to assure that

no components in the valve package are subjected to a high

temperature which may damage seals or other materials.

Many two-position electric control valves, depending on

valve operation, are provided with a manual-opening lever.

This lever should be placed in the “open” position during

all soldering or brazing operations. Valve bodies should be

wrapped with a wet rag to help dissipate heat encountered

during brazing.

Loading...

Loading...