37

KHF - SERIES A FAN COIL UNITS

INSTALLATION, OPERATION, AND MAINTENANCE MANUAL

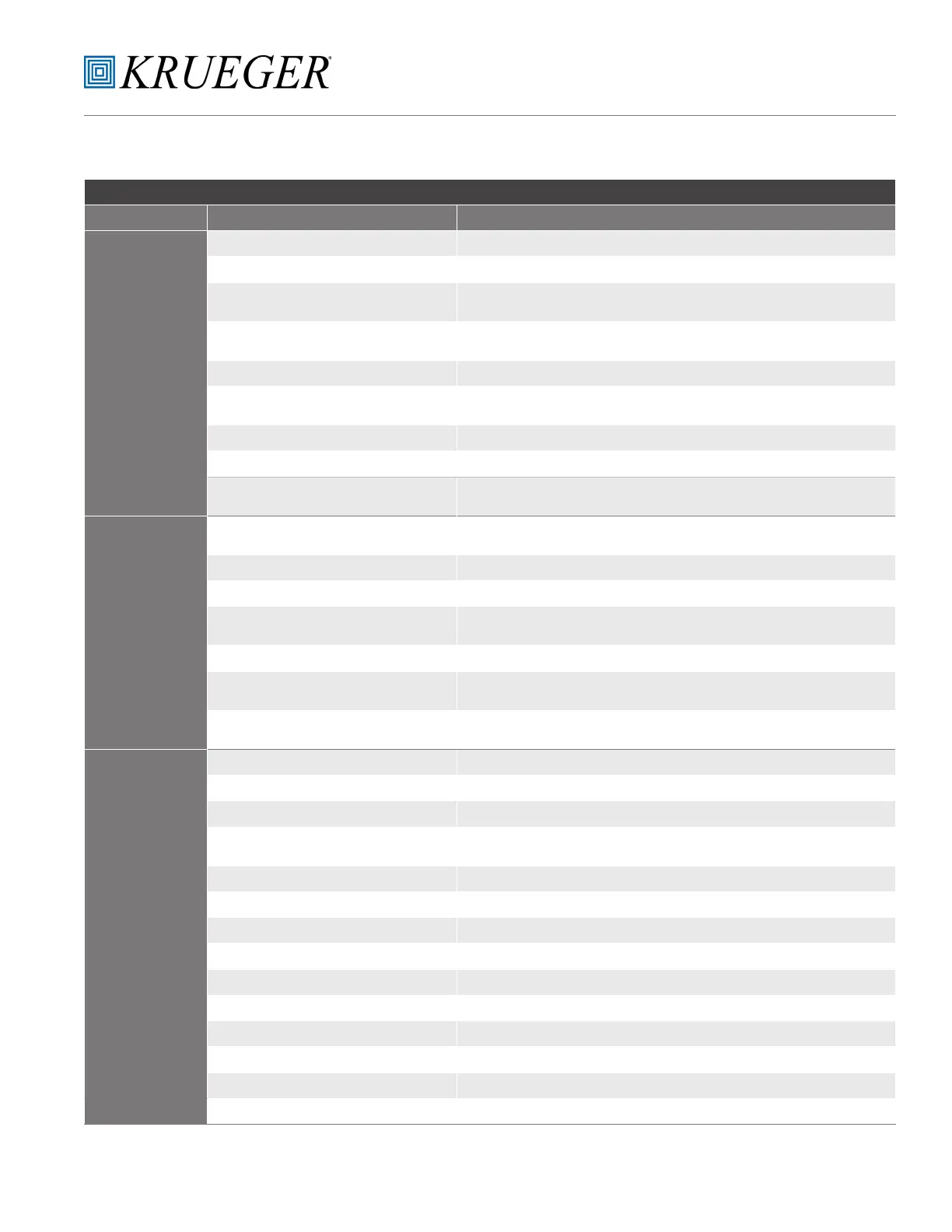

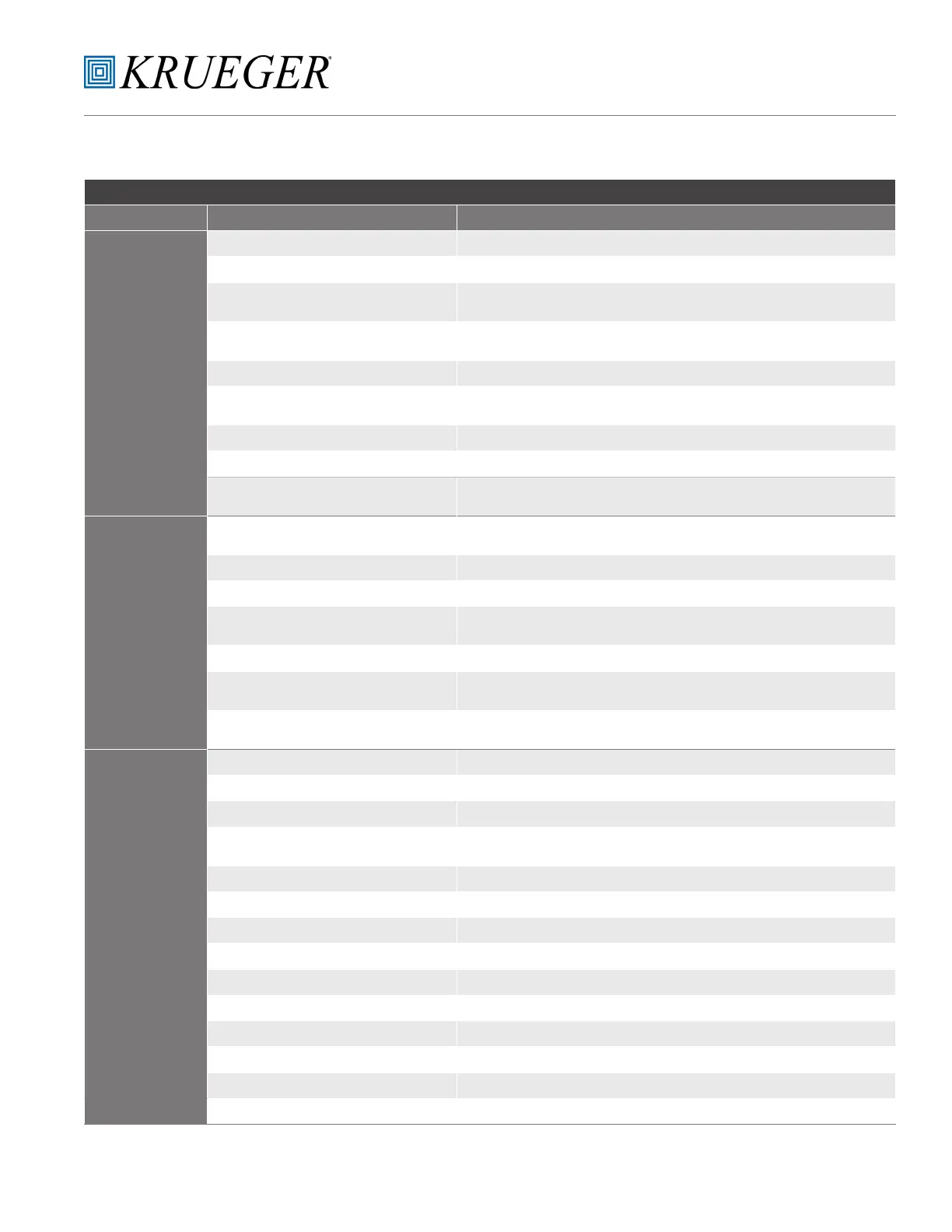

TROUBLESHOOTING (CONTINUED)

PSC MOTOR (CONTINUED)

PROBLEM POSSIBLE CAUSE CORRECTIVE ACTION

FAN MOTOR STARTS

BUT STOPS.

[PSC MOTOR]

Voltage or ground loss at motor Verify proper voltage and ground at motor.

Blower blocked Clear blockage. Verify blower rotates freely with motor disconnected.

Loss of fan speed command

Verify operation of thermostat or controller. If 24v unit, verify fan speed command at relay board.

Refer to fan relay board troubleshooting guide.

Motor overloaded

Use amp meter to verify motor amps. Disconnect power to unit.

Verify motor rotates freely by hand with blower disconnected. If not, replace motor.

Open ductwork Verify ducts sealed properly.

Motor overheated due to lack

of airow

Verify dampers, if present, are not closed. Verify there are no obstructions in the discharge ductwork and/or at

the plenum opening. Verify lter is not dirty and does not obstruct airow.

Voltage or ground loss at motor Verify proper voltage and ground at motor power terminals.

Motor fault or end of life Replace motor.

Faulty motor harness

Reseat connector and verify operation. Disconnect motor harnesses and verify continuity.

Replace motor harness.

FAN SPEED

FLUCTUATES

[PSC MOTOR]

Fan speed adjustment outside operating range

If fan speed controller present, adjust fan speed control screw to full clockwise position.

Verify that motor speed stabilizes. Reduce adjustment.

Loose motor wiring Reseat motor connector. Tighten all motor connections.

Loose control wiring Verify and/or tighten all control connections.

Intermittent control device

Verify operation of any control device such as drain pan oat switch, freeze stat, thermostat, etc.

When in doubt, jumper out and verify fan operation.

Blower set screw loose Remove power from unit. Tighten screw onto motor shaft.

Improper duct connections

Verify proper ductwork to unit. Verify ductwork is installed per SMACNA and ASHRAE guidelines.

Improper ductwork can cause turbulence at the motor.

ESP (external static pressure) too high

Verify dampers, if present, are not closed. Verify there are no obstructions in the discharge ductwork and/or at

the plenum opening. Verify lter is not dirty and does not obstruct airow.

EXCESSIVE FAN

NOISE

Motor mounting bolts loose Tighten motor mounting bolts.

Motor shaft bent Replace motor.

Motor bearing end of life Disconnect power from unit. Verify motor rotates freely by hand with blower disconnected.

Motor overloaded

Verify static pressure per system design. Use amp meter to verify motor amps. Disconnect power to unit.

Verify motor rotates freely with power disconnected. If not, replace motor.

Motor end of life Use amp meter to verify motor amps. Replace motor.

Dirty lters Verify lters. Replace as needed.

Obstructed airow Verify blower is unobstructed. Verify no duct obstruction. Verify dampers are full open.

Improper duct connections Verify ductwork is installed per SMACNA and ASHRAE guidelines.

Static pressure too low Verify static pressure per system design.

Improperly balanced system Verify airow through connected ductwork

Fan wheel rubbing on fan housing Remover power from unit. Align wheel in housing.

Loose fan wheel Remover power from unit. Align wheel in housing and tighten.

Damaged fan wheel Inspect fan wheel to verify ns are not bent. Replace blower as needed.

Imbalanced fan wheel Inspect fan wheel. Replace as needed.

Loading...

Loading...