S-93

03-M-E3B, 03-M-DI-E3B, 03-M-E3BG WSM

DIESEL ENGINE

Oil Clearance between Crankshaft Journal and Crankshaft

Bearing 2

1. Put a strip of plastigage on the center of the journal.

2. Install the bearing case and tighten the baring case screws 1 to

the specified torque, and remove the bearing case again.

3. Measure the amount of the flattening with the scale and get the

oil clearance.

4. If the clearance exceeds the allowable limit, replace the

crankshaft bearing 2.

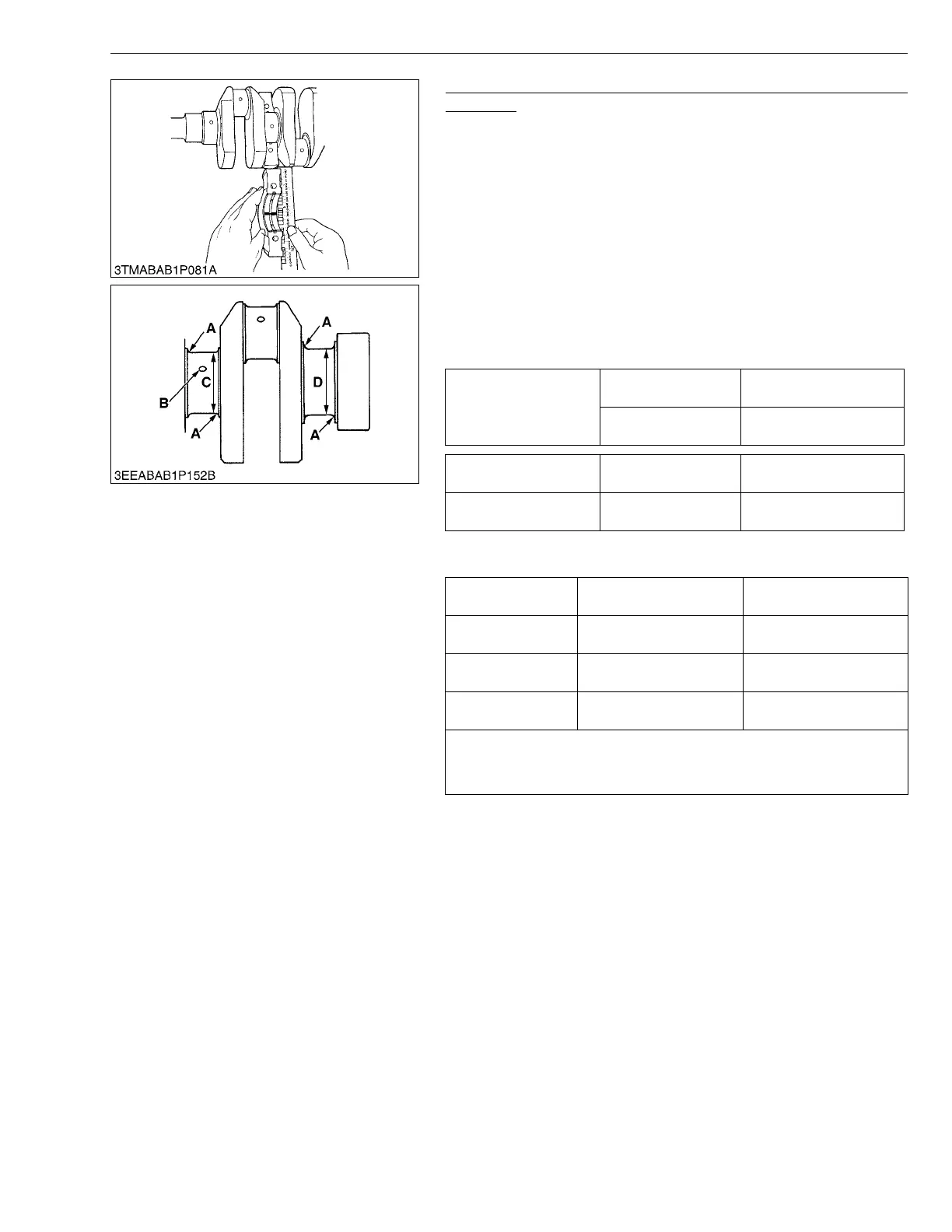

5. If the same size bearing is useless because of the crankshaft

journal wear, replace it with an undersize one referring to the

table and figure.

NOTEQ

• Be sure not to move the crankshaft while the bearing case

screws are tightened.

(Reference)

• Undersize dimensions of crankshaft journal

W1083821

Oil clearance between

crankshaft and

crankshaft bearing 2

Factory spec.

0.0400 to 0.104 mm

0.00158 to 0.00409 in.

Allowable limit

0.20 mm

0.0079 in.

Crankshaft journal O.D. Factory spec.

59.921 to 59.940 mm

2.3591 to 2.3598 in.

Crankshaft bearing 2

I.D.

Factory spec.

59.980 to 60.025 mm

2.3615 to 2.3631 in.

Undersize

0.2 mm

0.008 in.

0.4 mm

0.02 in.

Dimension A

2.8 to 3.2 mm radius

0.11 to 0.12 in. radius

2.8 to 3.2 mm radius

0.11 to 0.12 in. radius

*Dimension B

1.0 to 1.5 mm relief

0.040 to 0.059 in. relief

1.0 to 1.5 mm relief

0.040 to 0.059 in. relief

Dimension C, D

59.721 to 59.740 mm dia.

2.3513 to 2.3519 in. dia.

59.521 to 59.540 mm dia.

2.3434 to 2.3440 in. dia.

(0.4S)

The crankshaft journal must be fine-finished to higher than ∇∇∇∇

*Holes to be de-burred and edges rounded with 1.0 to 1.5 mm

(0.040 to 0.059 in.) relief.

Loading...

Loading...