FS-9120DN/9520DN

1-5-13

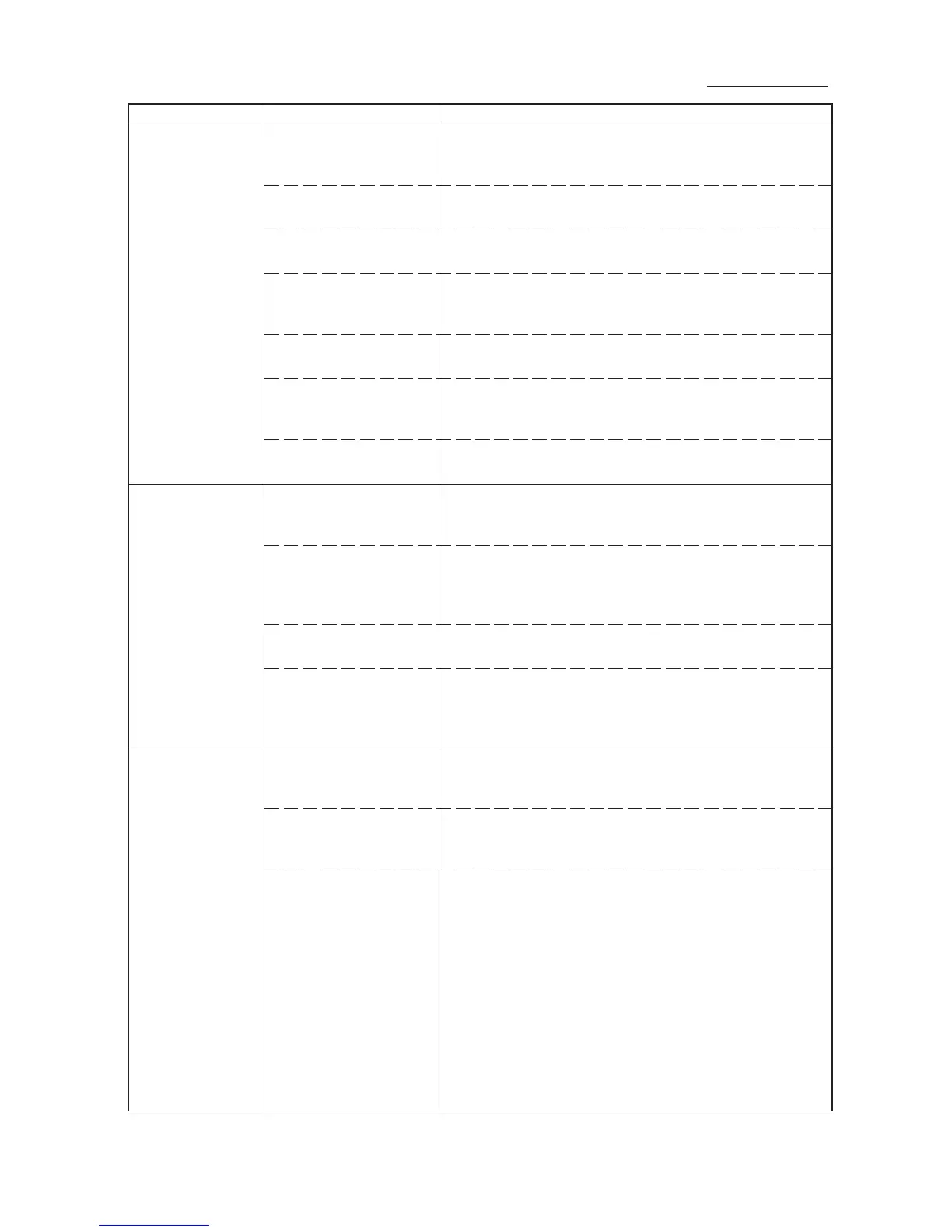

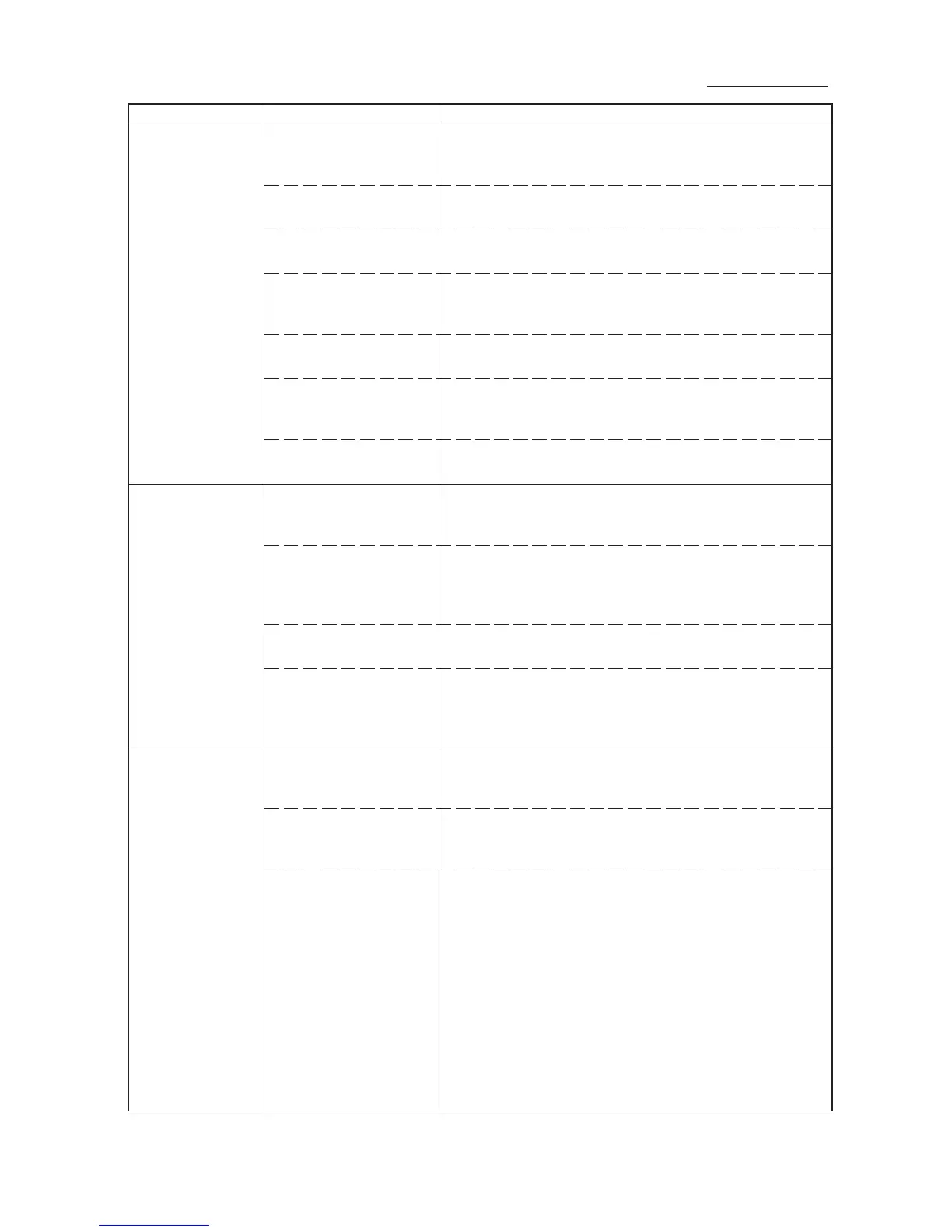

Problem Causes/check procedures Corrective measures

(21)

A paper jam in the

feedshift section is

indicated during

printing (jam in

feedshift section).

Jam code 52

(22)

A paper jam in the

switchback section

is indicated during

printing (jam in

switchback unit*).

Jam code 53

(23)

A paper jam in the

duplex section is

indicated during

printing (jam in du-

plex paper convey-

ing section 1).

Jam code 60

Check if the feedshift sole-

noid malfunctions.

Electrical problem with the

feedshift solenoid.

Broken feedshift switch

actuator.

Defective feedshift switch

or registration switch.

Defective engine controller

PWB.

Check if the registration

clutch malfunctions.

Electrical problem with the

registration clutch.

Broken feedshift switch

actuator, or switchback

eject switch actuator.

Defective feedshift switch.

Defective engine controller

PWB.

Defective switchback eject

switch.

Broken feedshift switch

actuator or duplex paper

conveying switch actuator.

Defective feedshift switch

or duplex paper conveying

switch.

Defective engine controller

PWB.

Run maintenance item U033 and select the feedshift solenoid on

the operation panel to be turned on and off. Check the status

and remedy if necessary.

Check (see page 1-5-38).

Check visually and replace the feedshift switch if its actuator is

broken.

Run maintenance item U031 and turn switch on and off manu-

ally. If "1" is not displayed when the switch is on or "0" is not dis-

played when the switch is off, replace switch.

When if feedshift switch and registration switch (above) are nor-

mal, replace engine controller PWB (see page 1-6-24).

Run maintenance item U032 and select the registration clutch

on the operation panel to be turned on and off. Check the status

and remedy if necessary.

Check (see page 1-5-38).

Check visually and replace the switch if its actuator is broken.

Run maintenance item U031 and turn the feedshift switch on

and off manually. If "1" is not displayed when the switch is on or

"0" is not displayed when the switch is off, replace feedshift

switch.

When if feedshift switch (above) is normal, replace engine con-

troller PWB (see page 1-6-24).

With 5 V DC present at CN5-2 on the switchback unit main

board, check if CN5-4 on the switchback unit main board re-

mains low when the switchback eject switch is turned on and off.

If it does, replace the switchback eject switch.

Check visually and replace the switch if its actuator is broken.

Run maintenance item U031 and turn switch on and off manu-

ally. If "1" is not displayed when the switch is on or "0" is not dis-

played when the switch is off, replace switch.

When if the feedshift switch and duplex paper conveying switch

(above) are normal, replace engine controller PWB (see page 1-

6-24).

*Optional.

Loading...

Loading...