1-2 Echo Liquid Handler User Manual

1.1 Acoustic Droplet Ejection

Acoustic droplet ejection (ADE) technology is the process of transferring

nanoliter volumes of liquid using acoustic energy. The Echo liquid handler

uses this technology to transfer fluid droplets from a source microplate to a

receiving surface.

The following is a simplified sequence of ADE events:

1. The Echo liquid handler creates an analog RF (radio frequency) wave.

2. The RF wave is amplified and transmitted to a focused acoustic

transducer, which transforms the RF wave into an acoustic pulse.

3. This acoustic pulse is transmitted into the fluid in the source

microplate well, causing the fluid to form a droplet that travels

upwards.

4. The droplet is captured by the receiving surface, which may be an

inverted destination microplate well or a flat substrate. Surface

tension of the fluid keeps it on the receiving surface.

For more information about Acoustic Droplet Ejection Technology, see

Appendix A

.

1.1.1 How does the Echo system work?

The Echo liquid handler uses the following basic steps to transfer liquid:

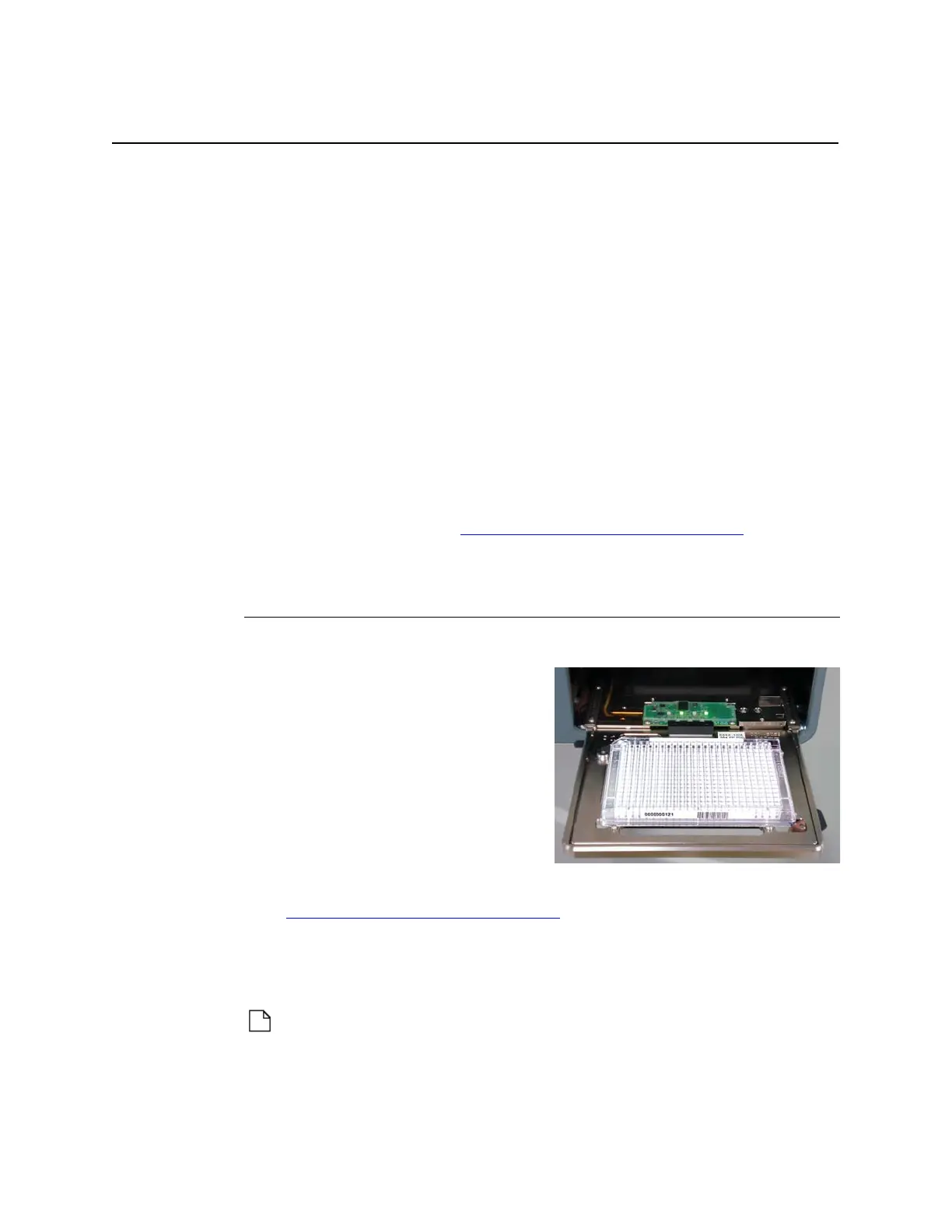

1. The robot (or operator) loads the

source microplate into the Echo

liquid handler. This step can also

be performed by a robot.

The Echo liquid handler retracts

the source microplate, then

surveys and measures the fluid

height in each well.

For aqueous solutions, the

reported value options will vary by fluid type. For more details, see

“

Diagnostic Survey” on page 5-39.

For DMSO-based solutions, the software reports DMSO/water

concentration (Echo 550 and Echo 555 only).

Note:

Loading source microplate

Loading...

Loading...