GENERAL CARE AND MAINTENANCE

© 2003-2018 Ken Cook Co.

SECTION

10

Bass l

10 - 7

SACRIFICIAL ANODES

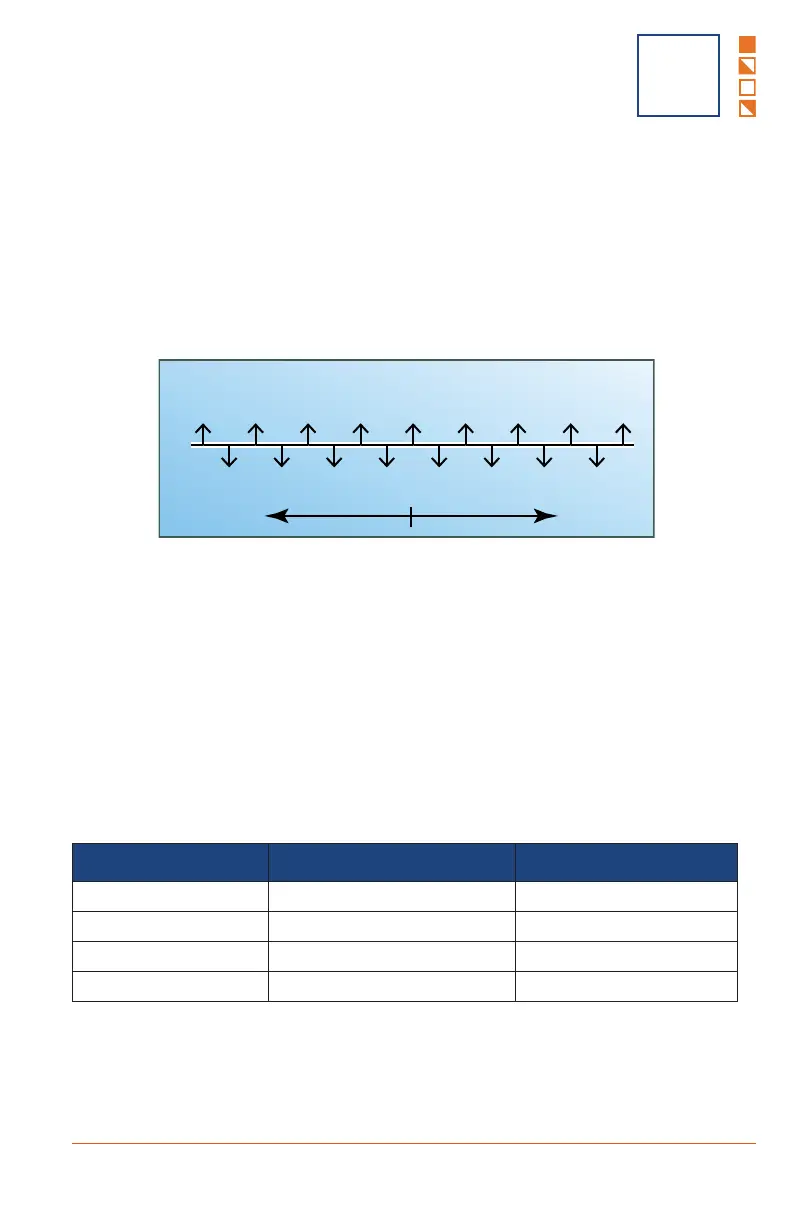

Anodes (sometimes called “zincs”) are used to protect hardware exposed to the

water. Since galvanic corrosion attacks the least “noble” metals first, less noble

metal anodes are used to purposefully “sacrifice” themselves, thereby protecting

the more noble metals of the drives, propeller, tabs, boarding platform and other

metal items below the waterline (such as underwater gear).

Anodes may be installed on the boat transom and/or bottom at the factory.

Additional anodes may be installed on the underwater gear as well as any metal

components exposed to raw water, such as heat exchangers and water cooling

jackets. Anodes are made in three different metals which must be matched to the

water type and local conditions. Most boats are equipped from the factory with zinc

anodes on the recommendation from engine and drive manufacturers. The anodes

that are installed on the trim tabs are typically zinc and are isolated from the boat

bonding system.

Selection, monitoring and replacement of the anodes on the transom, drives, trim

tabs, boarding platform supports and other underwater gear is the customer’s

maintenance responsibility. Any damage done because of lack of maintenance will

not be covered under warranty.

WATER TYPE ANODE MATERIAL REPLACE AT

Salt water Zinc 40% decomposition

Brackish water Aluminum 50% decomposition

Fresh water (clean) Aluminum/magnesium alloy 50% decomposition

Fresh water (polluted) Magnesium 40% decomposition

Least Active

Order of Activity of Metals:

(Most Noble)

Most Active

(Least Noble)

Aluminum/

Indium Alloy

Galvanized

Iron

Mild Steel Tin Naval Brass

(60% Copper

30% Zinc)

Brass

(60/40 Alloy)

Titanium Platinum

GoldSilverCopperZincMagnesium Aluminum

Passive

Stainless/Steel

Manganese

Bronze

Active

Stainless Steel

KC-6009

Loading...

Loading...