Integral T process thermostats

21/01/2019 / YAWE 0026 Maintenance 89

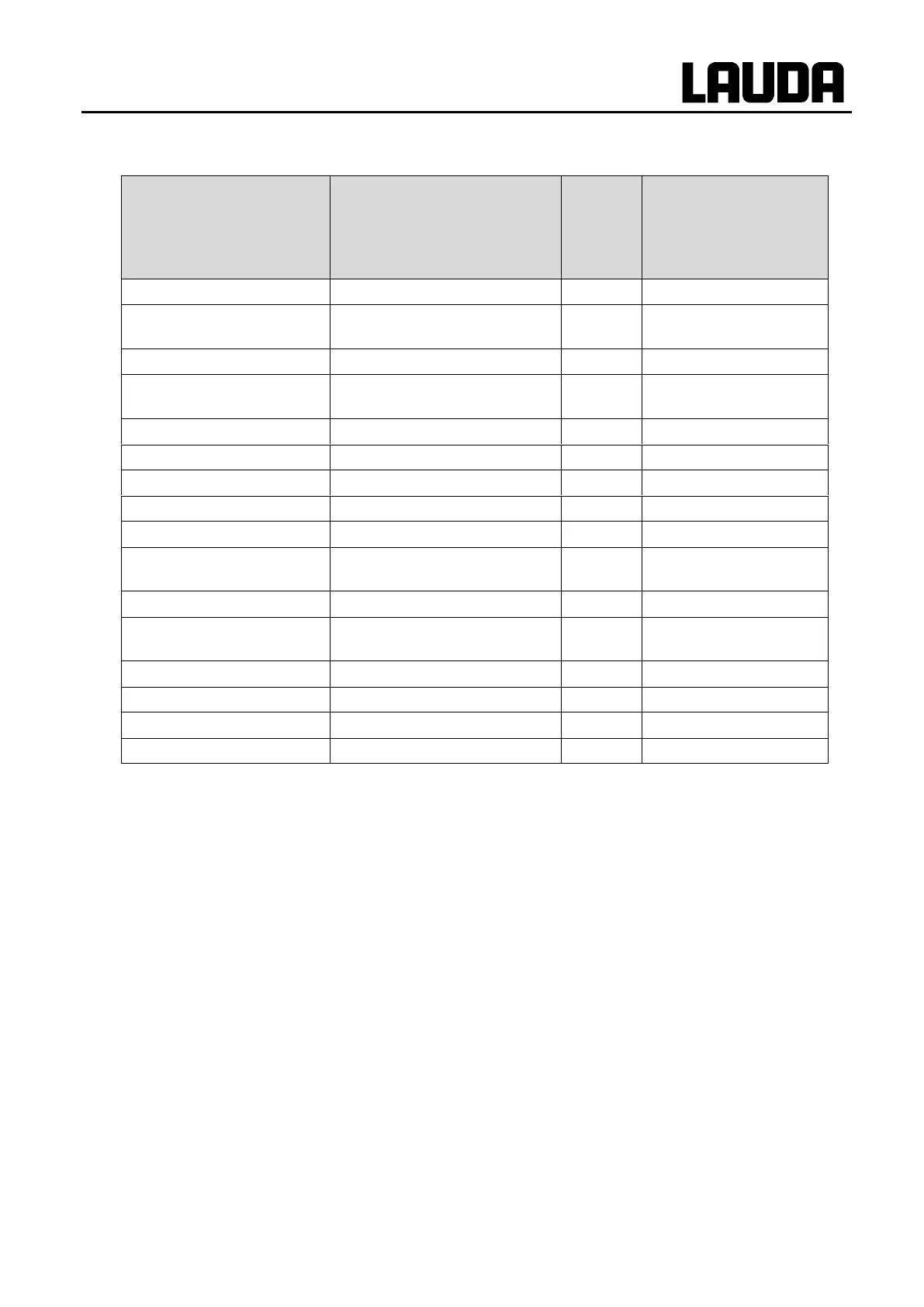

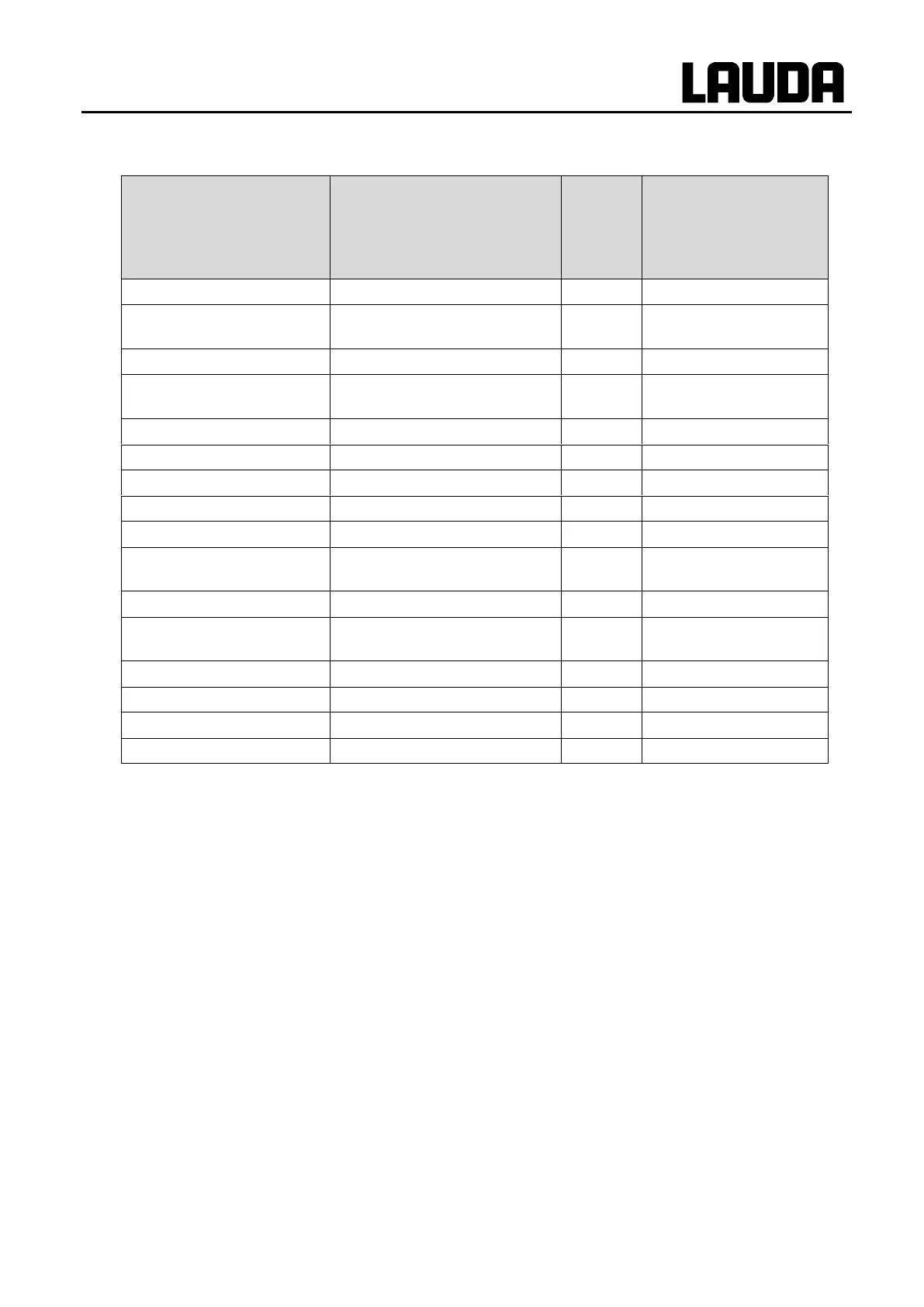

8.3 Servicing intervals

Mandatory for initial

operation and before any

longer unsupervised

operation, then with

recommended frequency

External condition of the

device

Analysis of heat transfer

liquid

Half-yearly (and as required)

External visual inspection

External visual inspection

Cleaning of air-cooled

condenser

Decalcifying the water

cooling circuit

Overtemperature protection

Low level alarm / warning

8.4 Inspecting the heat transfer liquid

If the heat transfer liquid becomes contaminated or degenerated, it should be renewed.

If required, the heat transfer liquid should be checked for fitness for use (e.g. when changing the

method of operation), or at least half-yearly. Further use of the heat transfer liquid is only permissible

if the inspection indicates this.

The test of the heat transfer liquid takes place according to DIN 51529; ("Testing and assessment of used heat

carrier media"). Source: VDI 3033; DIN 51529.

8.5 Protective cut-outs and fuses

Single-phase units are protected against excessive current by an over current cut-out built into the

mains switch. This switches off the power in case of a fault. Resetting as for switching on. If it cuts

out repeatedly, contact the service organisation.

3-phase units are fitted internally with overload cut-outs. These are accessible after removing the

side panels and possibly the cover.

Warning: Only by a qualified electrician!

If it cuts out repeatedly after reset, contact the service organisation ( Section 8.8).

Loading...

Loading...