Sentinel Plus Press Brake Guarding System Operation Manual LS-CS-M-073

Page 25

Original Language Version: 1.04 Released: 19/07/2017

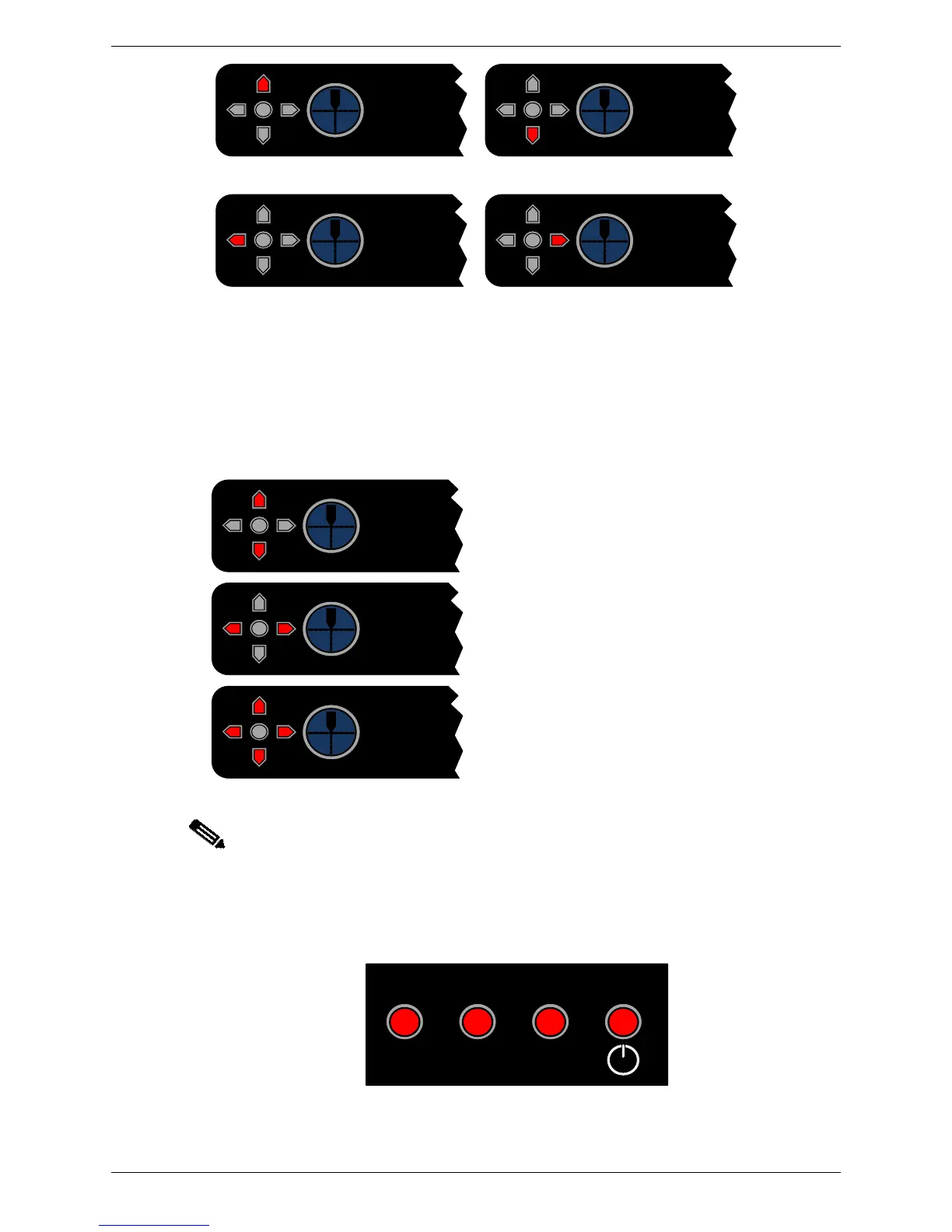

Move the receiver LEFT

(front of machine)

Move the receiver RIGHT

(rear of machine)

Figure 4-4: Receiver Alignment Correction

In some cases (extreme environmental conditions, unusual tool shapes, poor alignment

etc.) the automatic tool alignment may not be able to find the tool tip. Again, the receiver

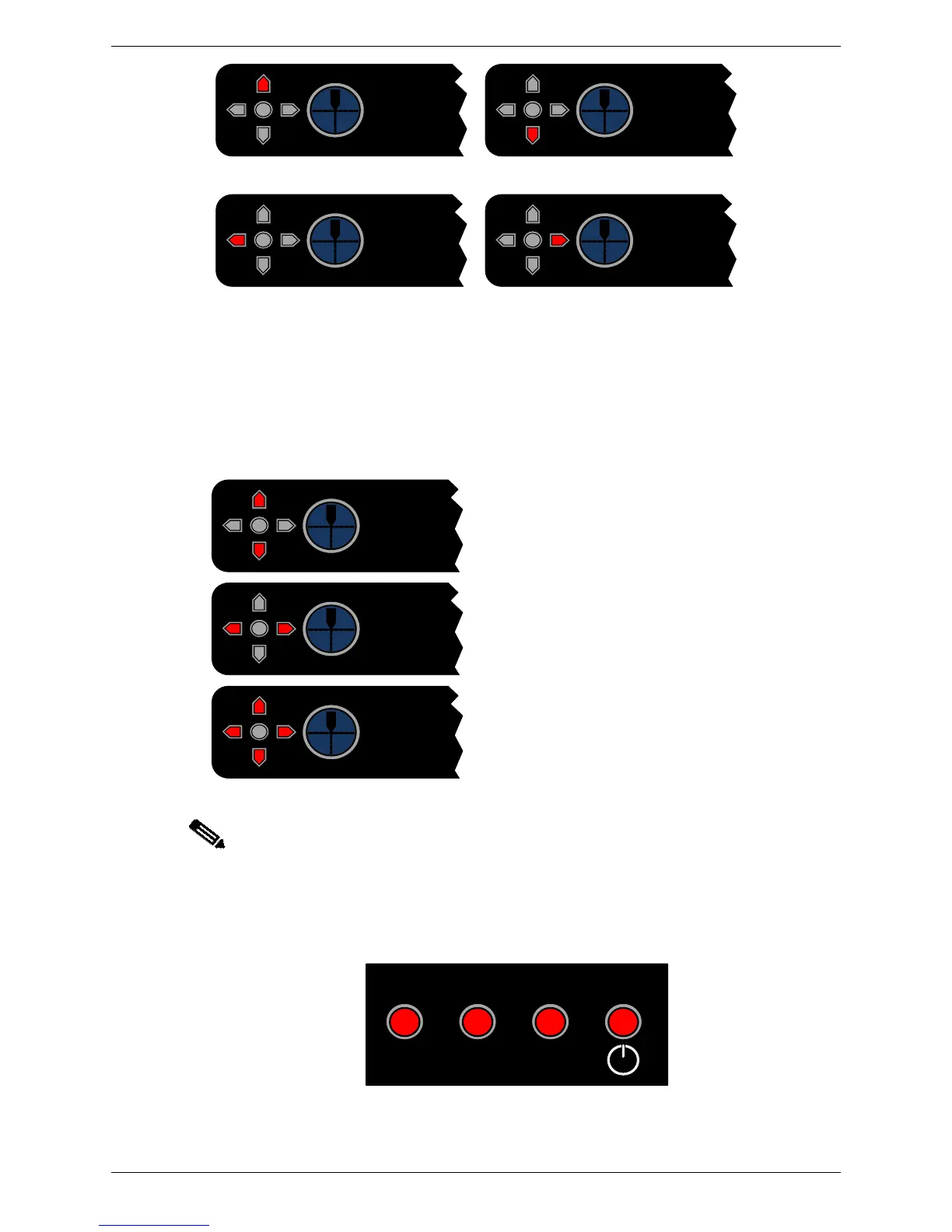

provides diagnostic information using the red LEDs.

The image captured by the receiver is too dark

to locate any tool silhouette. This may be

caused by an obstruction, or by a poor

alignment.

The image captured by the receiver is too light

to locate any tool silhouette. This may be

caused by a poor alignment, or very high

levels of ambient light shining on the receiver.

The tool tip location has been lost. This may

be caused by the power being cycled on the

receiver, the mute point being reset by the

operator, or the tool silhouette being lost.

Note:

It is the responsibility of the machine operator to ensure that the transmitter and

receiver are correctly aligned. Correct alignment is essential to ensure maximum

protection and productivity for the press brake operator.

LEDs on the side of the receiver indicate when an obstruction occurs to a protected region

(the front, middle or rear) as shown in Figure 4-5.

Figure 4-5: Block Laser Obstruction Indicators

Loading...

Loading...