9. Supply Air Delivery

Page 38

506457−01 05/10

9.2.6. Local Thermostat Mode, VAV staged units

ECTO 6.01 option 0 (default) or 12;

Staged Speed

.

ECTO 0.01 option 3 (MSAV)

Operation

(1)

Default ECTO

This configuration is a special case application

Cooling compressor 1 51% 0.05

where the blower speed is staged by the factory

installed VFD for fixed speeds for different op

Cooling compressor 2 51% 0.14

installed VFD for fixed speeds for different op-

eration There are seven different speed stages

Cooling compressor 3 51% 0.15

era

on.

ere are seven

eren

spee

s

ages,

one for each cooling compressor stage (4), one

Cooling compressor 4 51% 0.16

,

for ventilation

one for heatin

and one for o

era-

Ventilation or economizer free cooling 51% 0.03

,

tion during smoke alarm modes. The blower is

Smoke Alarm Modes 51% 0.02

enabled by a G demand. This table shows the

Heating 51% 0.04

default staged speeds. (1)

Staged % speed must be adjusted for each operation.

9.2.7. L Connection Network, VAV units

ECTO 6.01 option 4, 5, 6, or 7;

ECTO 0.01 option 63

This configuration is used for L Connection VAV zoning systems. There are four different setpoints: one for cooling, one for

ventilation, one for operation during smoke alarm modes, and one for heating. Network commands energize the blower.

Blower will cycle with demand unless ECTO 6.17 is set to 1. In that case the blower will operate continuously during occupied

periods and will cycle during unoccupied periods. Network commands controls occupied/unoccupied periods.

All delays as described in Local Tstat Mode still apply. Blower speed is controlled by the factory installed VFD between a

minimum and maximum speed to maintain duct static pressure setpoints. There are three different setpoints, one for cool-

ing, one for ventilation and one for operation during smoke alarm modes. The M2 controls the duct static pressure by reading

the duct pressure and varying the blower speed on units with VFDs

The min/max. speed and static pressure setpoints are listed below:

Minimum Position Maximum Position Duct Static SP

Operation

Default ECTO Default ECTO Default ECTO

Cooling 50% 0.06 100% 0.08 1.00"w.c. 0.05

Ventilation 50% 0.06 100% 0.08 1.00"w.c. 0.03

Smoke Alarm Modes 50% 0.06 100% 0.08 1.00"w.c. 0.02

Heating

50%

0.07 100% 0.08 1.00"w.c. 0.04

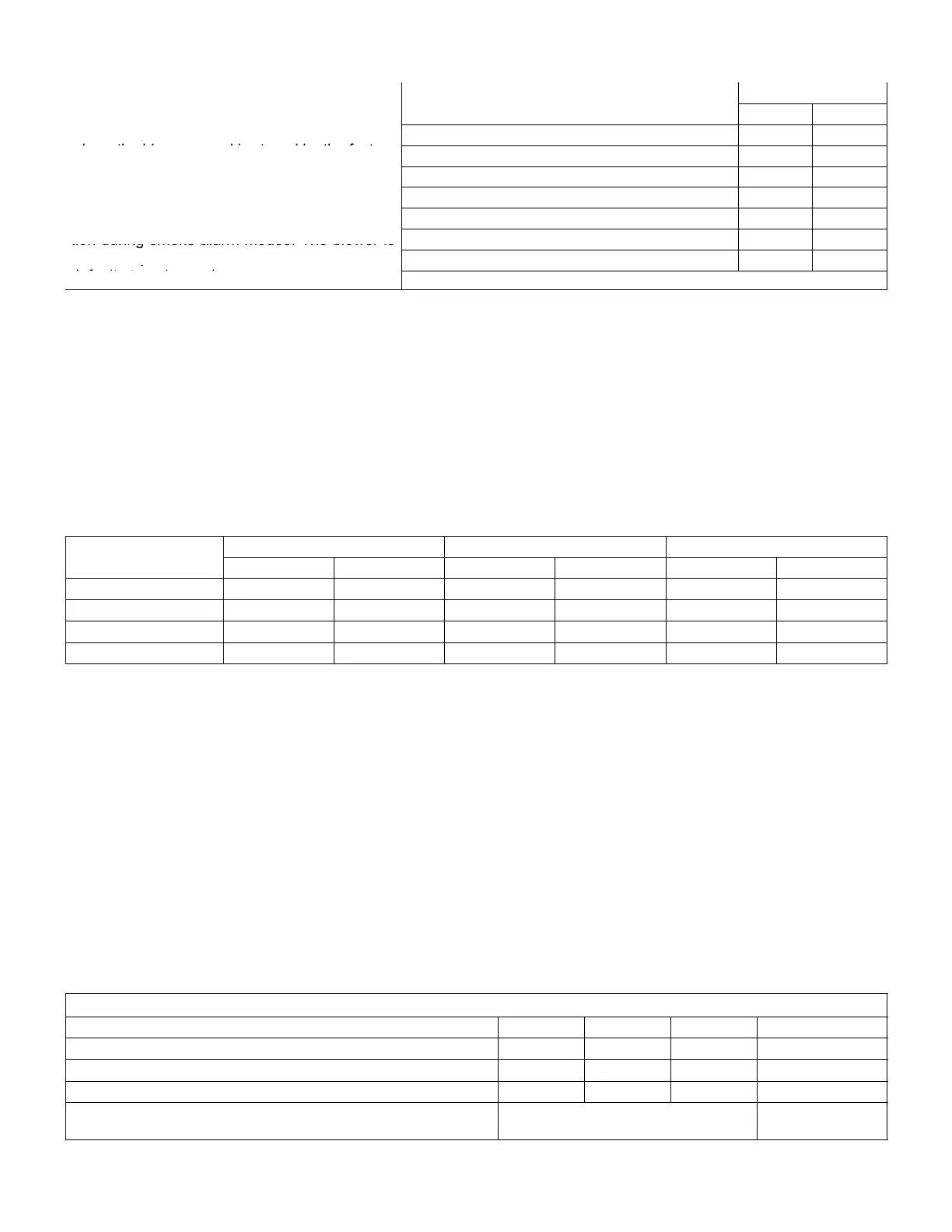

9.2.8. VAV Staged Units: A Box (3− to 5−ton units)

Energence A Box 3− to 5−ton units use a single, 2−step capacity, compressor. These units use a variable output blower that

operates at high or low. (The 6−ton Energence A Box has a single capacity compressor, and a single speed blower,

so it is not an MSAV type of unit, and the following does not apply to it.)

High efficiency Energence A Box units use a direct−drive ECM constant torque motor. The blower runs at a selected high

or low output depending on unit operation. The actual blower speed and CFM delivered will depend on the flow restriction as

well as the percent output. The blower output for each mode of operation has been factory set, but it will need to be adjusted

based on the installed ductwork and the air delivery required for the application. The table shows the default blower output

and the ECTO location where the output value for the each mode is stored. The default blower output selection for smoke

mode operation is the same as high speed, but it can be set to a different value using ECTO 0.02.

Standard efficiency Energence A Box unit use a belt−drive 2−speed motor. The blower runs at low or high speed depend-

ing on unit operation, but the speed is not ECTO−selectable. High speed blower runs during smoke mode operation. The

table also shows, for units equipped with an economizer or motorized outdoor air damper, the damper percent output when

the blower is running and the space is occupied. The default value of 101 for ECTO 5.24 is used to indicate that the min

position potentiometer on the M2 board is used to set the high−blower damper position. Setting ECTO 5.24 to a value in the

range of 0−100 causes this value to be used for the damper minimum position during high blower operation.

High Efficiency Factory Settings (as percent output) − A Box (3− to 5−ton units)

Operation 3− ton 4− ton 5− ton ECTO

Cooling low, Free cooling low, Ventilation low 28 40 36 0.05

Cooling high, Free cooling high, Ventilation high, Heating 55 80 59 0.04

Smoke alarm modes 55 80 59 0.02

Minimum damper during low blower

Minimum damper during high blower

30

101

0.09

5.24

Loading...

Loading...