9. Supply Air Delivery

Page 41

PRODIGYT M2 UNIT CONTROLLER

B Start system. Analog output value will be at the ManRS value (%).

C Monitor system. System should be stable. If system is not stable at this point check for other problems. Adjusting the PID

parameters will not solve this problem.

D If system is stable, gradually increase the P" parameter until system starts oscillating (moving above and below

setpoint, continuously).

E Reduce the P" parameter to 40−70% of the value set in step 6.

F Gradually start adding some I" by setting the I" ECTO parameter to 127 and reduce setting until the steady state

error (offset) is reduced to an acceptable level.

G If necessary, increase the D" parameter to reduce overshoot. Use of D" can increase settling time and/or lead to

instability.

H NOTE − In most cases, it’s best to not use any D" parameter.

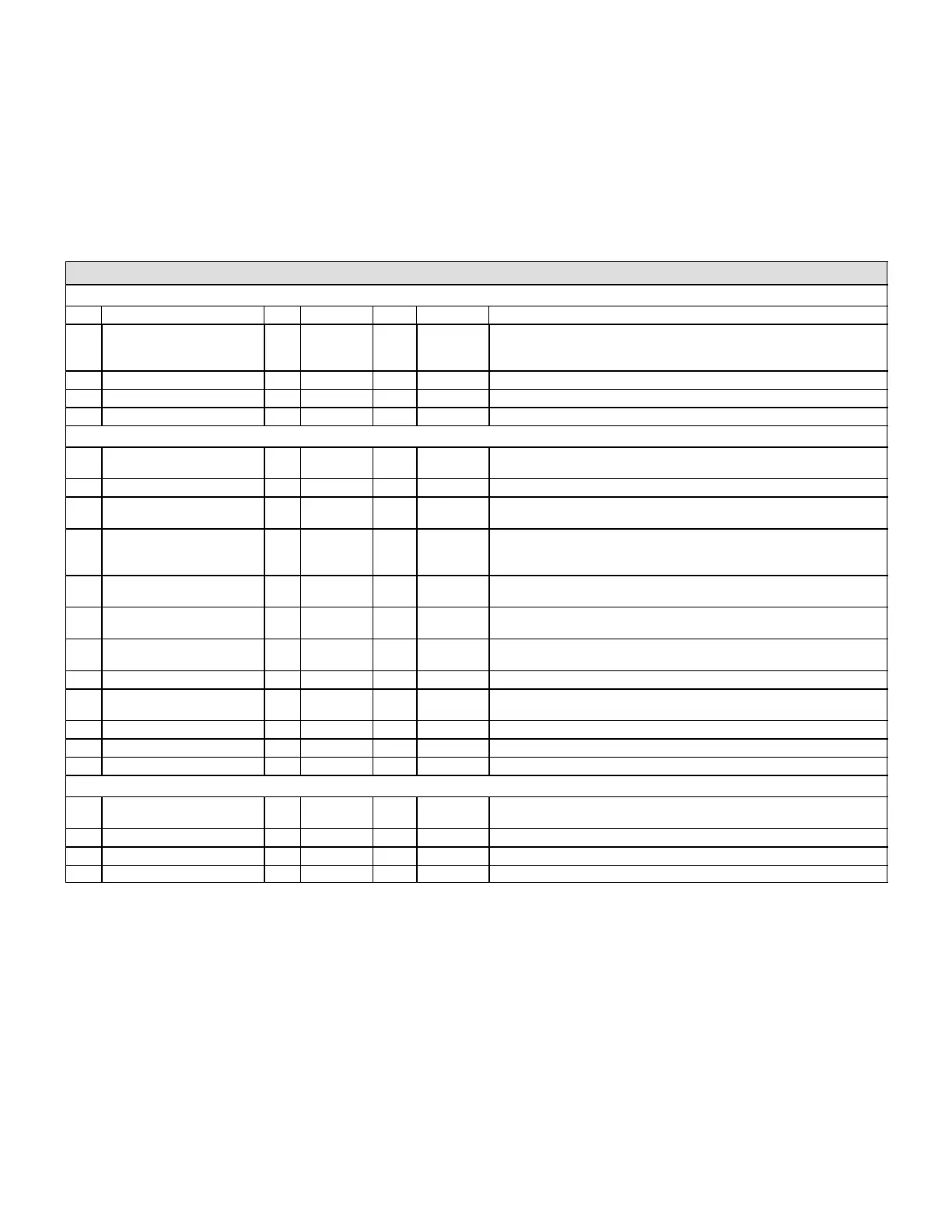

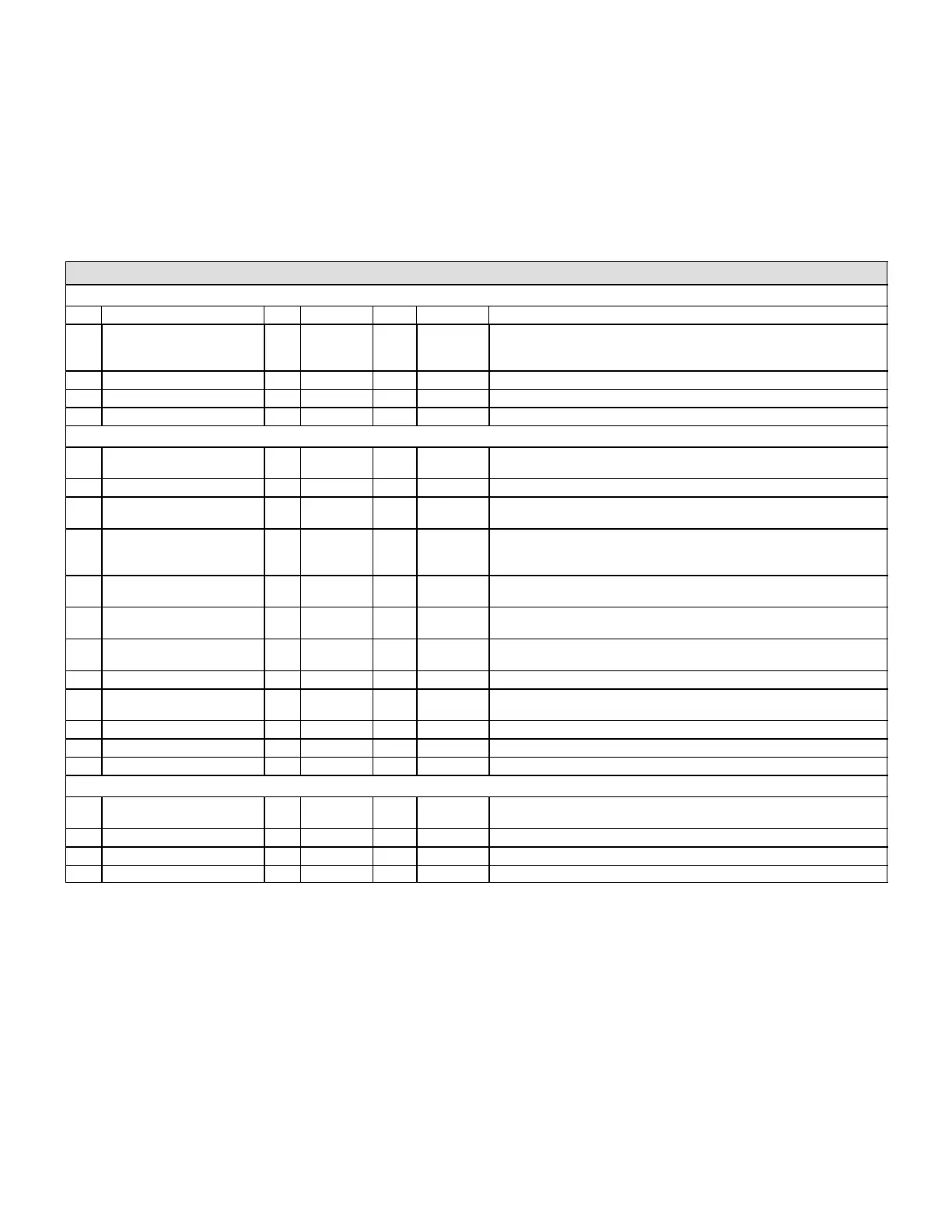

Table 30. Summary of PID Constants ECTO Parameters

Variable Air Delivery PID Constants

No. Name Min Default Max

Units Description

0.09 VAV_PID_ManRS

0

0

60

60

100

100

Counts

P:%

VAV supply PID manual reset value. If minimum output, ECTO 0.06 or

0.07 is greater, a computed ManRS value is used. See ECTO 0.06 and

0.07.

0.10 PID_P_Constant 0 17 127 Counts VAV or CAVB supply PID Proportional constant.

0.11 PID_I_Constant 0 12 127 Counts VAV or CAVB supply PID Integral constant.

0.12 PID_D_Constant 0 0 127 Counts VAV or CAVB supply PID derivative constant.

VAV Exhaust Fan PID Control Constants

8.22 Exh_Fan_ManRS

0

0

50

50

100

100

Counts

P: %

Exhaust fan PID loop manual reset value.

Stg_1_Off_Delay 0 100 200 A:Sec. Stage 1 off−delay. (Only used for 2 stage operation)

8.23

Exh_Fan_PID_P_

Constant

0 20 255 Counts

Exhaust fan PID loop proportional constant. The P constant must be

limited to 127. Recommended setting = 17.

Stg_2_SP

0

0

−0.5

.78

20

−.42

10.0

100

0.5

R:Volts

P:%

M:"w.c.

Staged 2 setpoint.

8.24

Exh_Fan_PID_I_

Constant

0 64 255 Counts

Exhaust fan PID loop integral constant. The I constant must be limited

to 127. Recommended setting = 12.

Stg_2_DB

0

0

64

0.25

100

1.0

P:%

L:"w.c.

Staged 2 deadband.

8.25

Exh_Fan_PID_D_

Constant

0 0 127 Counts Exhaust fan PID loop derivative constant.

Stg_2_On_Delay 0 0 254 A: Sec. Staged 2 on−delay.

9.08 AO1_PID_ManRS

0

0

50

50

100

100

Counts

P:%

Analog output channel 1 PID loop manual reset value.

9.09 AO1_PID_P_Constant 0 0 127 Counts Analog output channel 1 PID loop proportional constant.

9.10 AO1_PID_I_Constant 0 0 127 Counts Analog output channel 1 PID loop integral constant.

9.11 AO1_PID_D_Constant 0 0 127 Counts Analog output channel 1 PID loop derivative constant.

General Purpose PID Control Constants for GP Analog Output 2 (TB22−12)

9.19 AO2_PID_ ManRS

0

0

50

50

100

100

Counts

P:%

Analog output channel 2 PID loop manual reset value.

9.20 AO2_PID_P_Constant 0 0 127 Counts Analog output channel 2 PID loop proportional constant.

9.21 AO2_PID_I_Constant 0 0 127 Counts Analog output channel 2 PID loop integral constant.

9.22 AO2_PID_D_Constant 0 0 127 Counts Analog output channel 2 PID loop derivative constant.

Loading...

Loading...