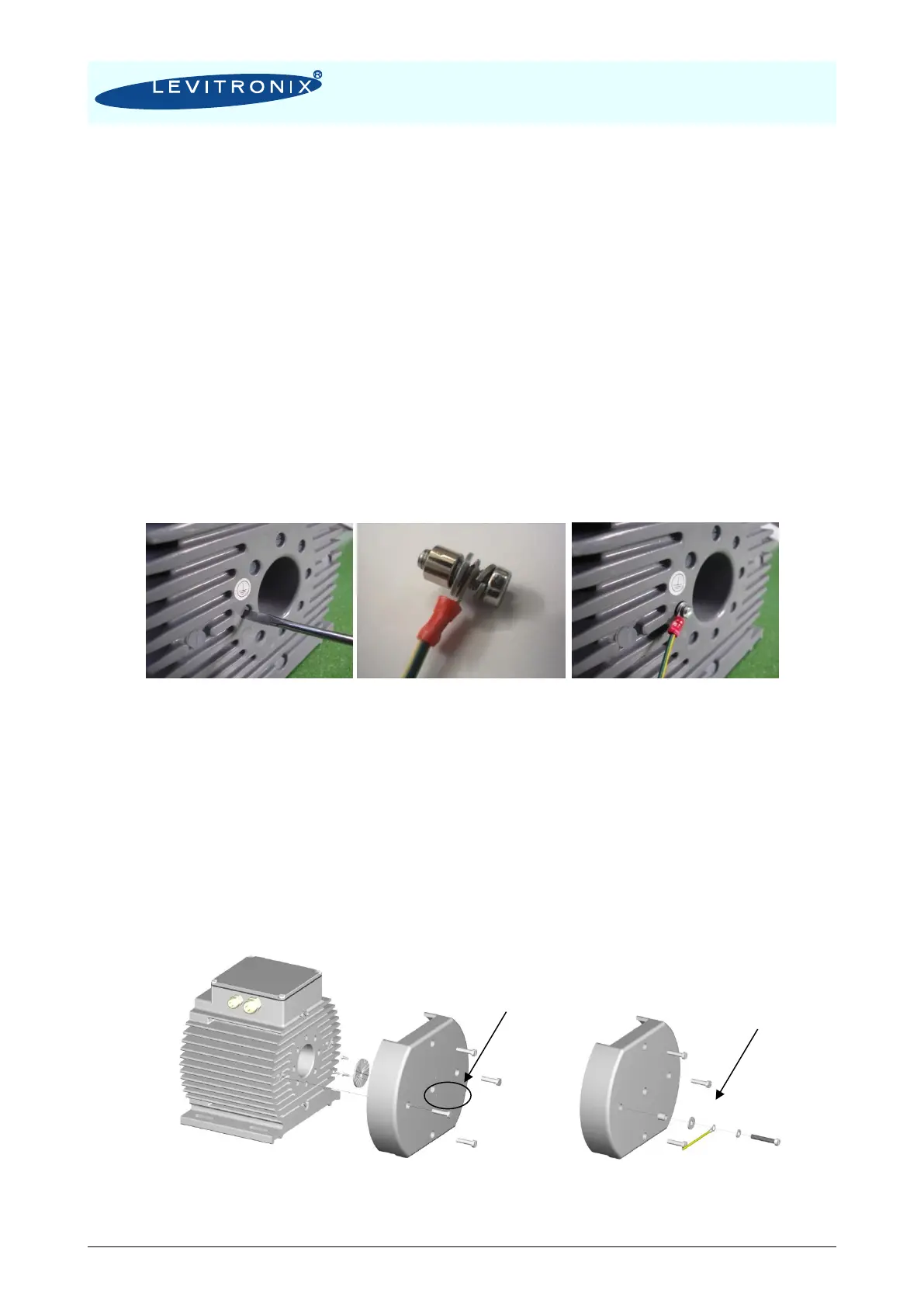

An Ex conform solution is needed for the motor cable to leave the Ex area (see Figure 5). One option is an

Ex certified cable sealing system as listed in Table 4 (see Pos. 8) and shown in Figure 2.

A protective earth wire (minimum Wire Gauge AWG14, copper diameter 1.63 mm, cross section 2.08 mm

2

)

shall be attached to the Ex specific motors by following the instructions outlined below.

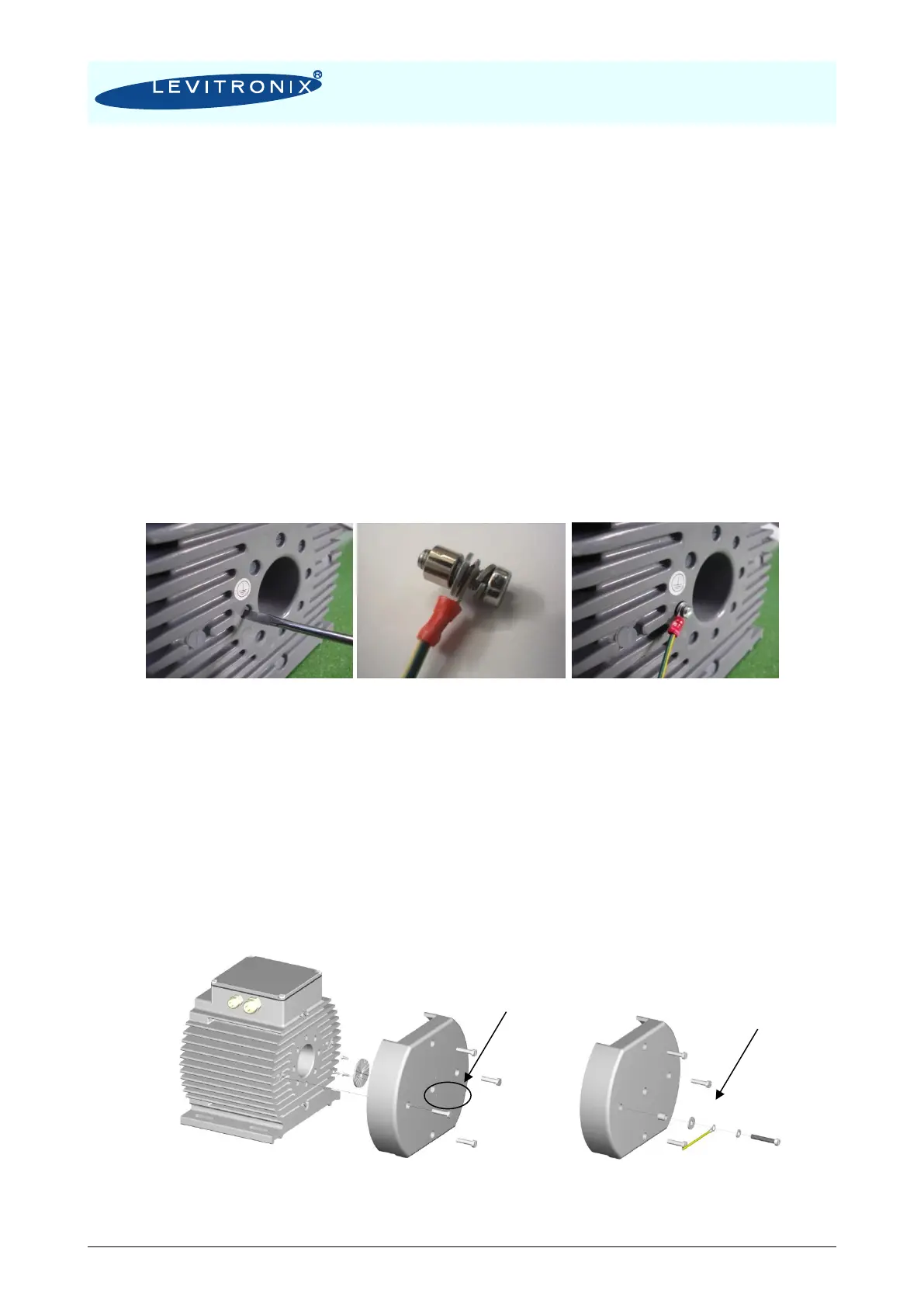

1) Motors used without cooling module ACM-4000.3

A Protective earth wire shall be attached to the Ex specific motor housing by using one of the eight

M8 threads on the backside of the motor.

• Remove one of the eight M8 screws on the backside of the motor

• Use a crimp-type end together with a spacer sleeve to connect an earth wire

• Attach the grounding wire with a M8 stainless steel screw to the motor according to Figure

30. Prevent the screw attachment from self-loosening and from twisting e.g. by fixation of the

earth cable.

Figure 30: Attachment of a protective earth wire to the backside of the motor

2) Motors used with cooling module ACM-4000.3

A Protective earth wire shall be attached to the Ex specific motor housing by using one of the four

M8 threads on the backside of the motor.

• Mount the cooling module ACM-4000.3 to the motor according to (Figure 11)

• Remove one of the four M8 screws on the mounted cooling module

• Use a crimp cable lug to connect the earth wire

• Attach the crimp cable lug with a M8x40 mm stainless steel screw, a washer disc and a

spring lock washer to the motor through the cooling module (Figure 31)

Figure 31: Attachment of a protective earth wire to the backside of the motor through ACM-4000.3

Loading...

Loading...