3.2.2 Instructions for Electrical Installation

1. Remove the DC power supply from the converter.

2. Remove the interface connector on the connector box (see Figure 16).

3. Attach the necessary wires (AWG 14-26) according to the pin specifications in Table 9, Table 10 or Table 11.

Strip the sheath approximately 3mm from the wires end. Insert the core into the connector up to the end and

tighten the screw. Confirm that the wires are securely fixed by pulling it by hand.

4. Note: The Field Ground (FG) represents an additional ground potential, which is connected internally to the

signal ports of the converter via varistors. Depending on the specific setup, it might be advantageous from an

EMC perspective to connect the FG to the PE (protective earth). However, in case the FG is connected to PE

the entire grounding concept of the field installation has to be considered in order to avoid stray and

compensating currents triggered by electrical potential differences. If compensating currents between PE and

Ground may occur, the FG should not be connected.

5. For usage of a fuse at the power input slow-blow type with a current rating of the converters (see Table 5) and

25% additional margin is recommended. Consider the inrush current of the converters (see Table 5) during

power start-up, when choosing the fuse type and the AC/DC power supply.

6. Mount the bus connector to the converter and tighten the 2 connector screws.

7. Before powering on, check again all wiring connections. Confirm that the terminals are securely fastened and

that there is no possibility of short circuit.

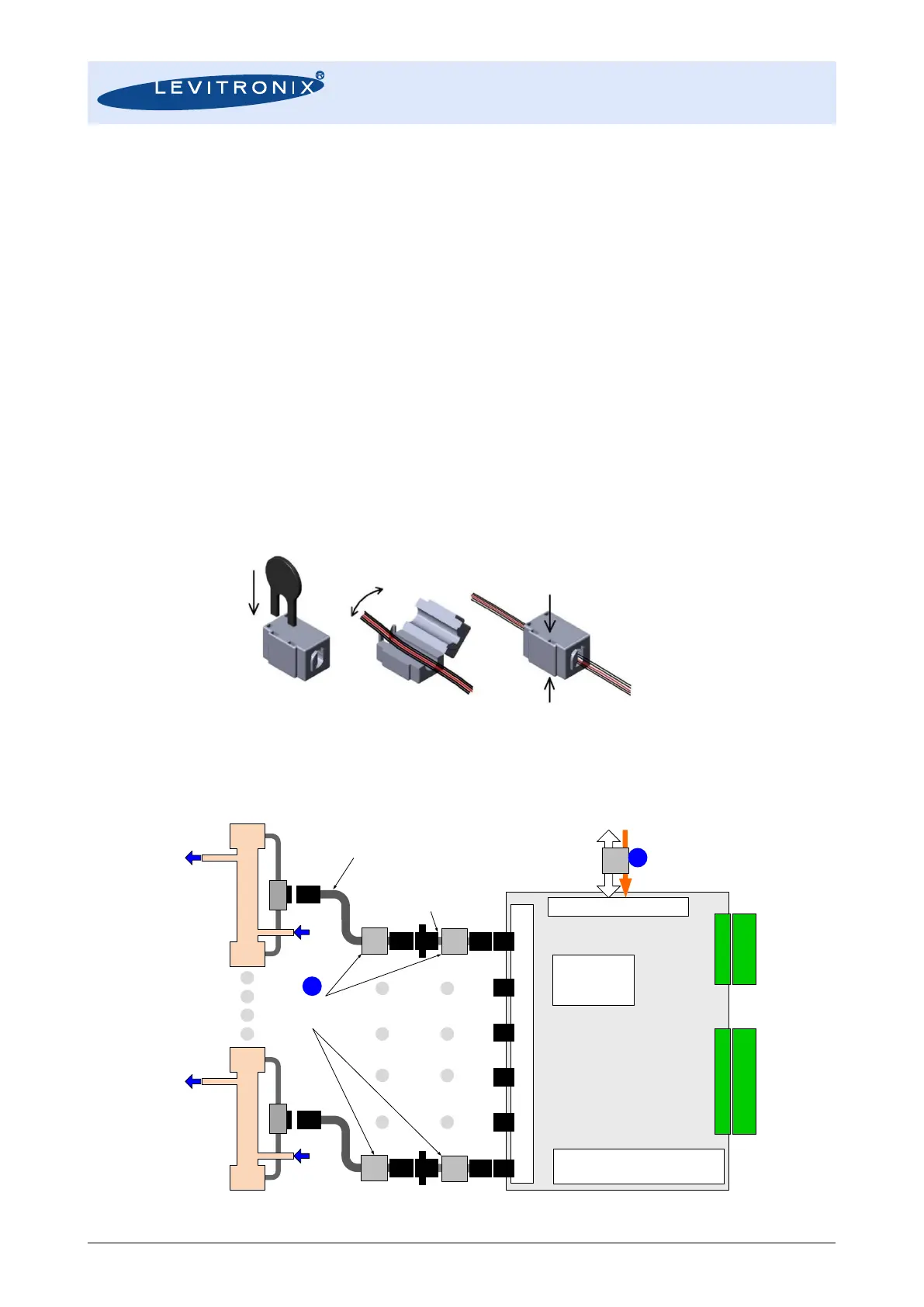

8. For proper EMI behavior of the LFC-6CIO-PC a ferrite is needed. This can be ordered according to Table 3

and assembled according to Figure 17. All bus wires shall be covered and the ferrite shall be placed at a

distance not longer than 15 cm from the connector box of the converter (see also Figure 10).

Figure 17: Mounting of EMI ferrite for bus wires of LFC-6CIO-PC (See Table 3 for order information)

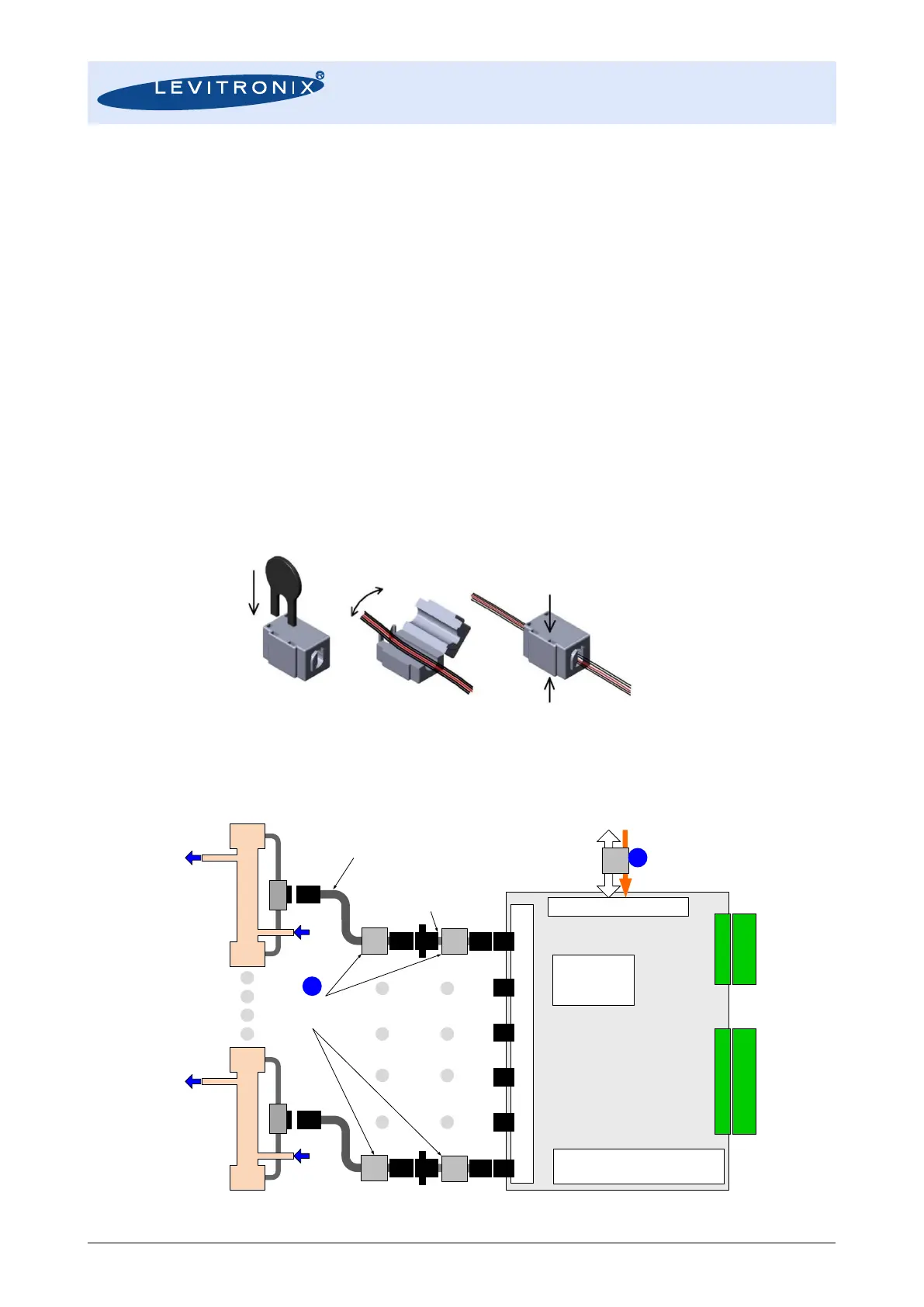

9. If multiple LFC-6CIO-PC are stacked as illustrated in Figure 16, every sensor cable shall be configured with a

ferrite according to Figure 18 (see Table 3 for order information) in order to avoid cross talking of the sensor

signals. The ferrites shall be placed as near as possible to the beginning of the sensor cable (near to the

plastic connector).

Figure 18: EMI ferrites for sensor cables when stacking multiple LFC-6CIO-PC

LEVIFLOW

®

Converter LFC-6CIO-PC

(6-Channel with I/O Signals)

4-Digit Display

Zero Adjustment

Address Setting for RS485

Piezo Transducers In

-/Output

Signal/Power Bus Connector

Power Supply: 24 VDC

RS485 (MODBUS)

- Configuration with PC Software

- Data Reading

Digital

Signal Processor

DSP

Analog Output

Connector

Digital I

/O

Connector

Analog Outputs:

6 Channels

Digital Outputs:

6 Channels

Digital Inputs:

6 Channels

Adaptor/Extension Cable

Wallmountable connector

for cabinet mounting

Interconnect Cable

Various lengths.

Direct connection possible.

Single

-Use Sensor LFS

-xxSU

Single

-Use Sensor LFS

-xxSU

EMI Ferrite for Sensor Cables

For stacking of multiple

converters necessary.

EMI

Ferrite

EMI

Ferrite

EMI

Ferrite

EMI

Ferrite

EMI

Ferrite

Loading...

Loading...