User Manual for LEVIFLOW

®

LFS-SU Flowmeters

www.levitronix.com

PL-4509-00, Rev09, DCO# 21-230

5 Inspection and Maintenance

The LEVIFLOW

®

ultrasonic flowmeters do not require special maintenance since there are no moving parts

that can be subjected to wear and tear. However, the following periodical checks are recommended to ensure

smooth and reliable operation:

1. Check for excessive mechanical stress onto the flow sensor body for example caused by bended piping.

2. Inspect for loosen connections caused by excessive pipe vibrations.

3. Inspect the sensor visually for any deposits, excessive bubbles or foreign materials in the measuring tube.

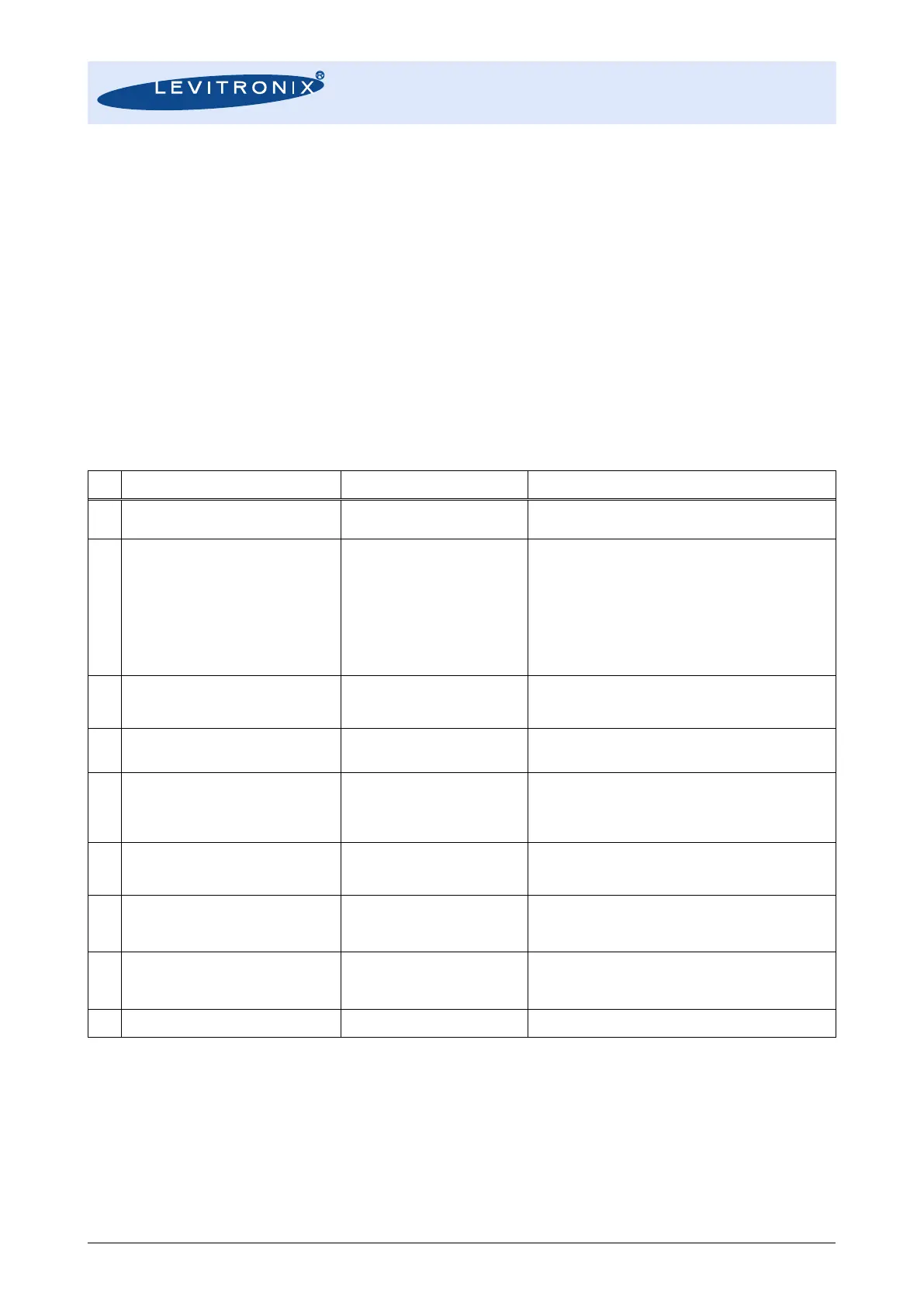

6 Troubleshooting

6.1 Common Troubles

“0-Er” indication on converter display

Zero adjustment is not working

properly.

Check if the circuit is filled with liquid and the flow is actually

zero, and conduct zero adjustment again

“b-Er” indication on converter display

Incorrect signal received from

measurement in the sensor.

- Check if measuring tube is filled with liquid

- Check if there is something in the measuring path

disturbing the ultrasonic wave (bubbles, solid substances

etc)

- Check if excessive noise is generated in the neighborhood

of the sensor (heavy devices like motors, high voltage

cables etc)

- Check if the cables are connected correctly and not

damaged

“c-Er” indication on converter display

Parameter communication to

sensor is not working properly

or corrupt data on sensor.

- Check if sensor is connected.

- Check sensor cabling and connection.

- Disconnect and reconnect sensor.

“SHrT” indicat. on converter display

Short-circuit on flow sensor

transducer.

- Check sensor cabling and connection for damage.

- Disconnect and reconnect sensor.

- If issue is still not solved, replace sensor cable.

Zero flow is indicated even if there is

flow in the hydraulic circuit

Wrong parameter and

mechanical setup of sensor or

zero adjustment performed

under flow conditions.

- Check if the parameters have been set to the optimal

values

- Check if the flow direction is correct

- Redo zeroing at 0 lpm

Zero flow is indicated at flow level

below cut-off value.

Standard cut-off value as

shown in Table 6 is not

adequate for application.

- Adapt lower cut-off value with Levitronix

®

Service Software

The flow indication does not match

the real flow

Wrong parameter settings,

excessive bubbles or solids in

the measurement path.

- Check if the parameters in the converter are set correctly

- Inspect the flow path for stagnating solids

- Inspect the measurement path for excessive bubbles

Above full scale flow is indicated or

the flow signal is unstable

Wrong parameter settings,

excessive bubbles or solids in

the measurement path.

- Check if the parameters in the converter are set correctly

- Inspect the flow path for stagnating solids

- Inspect the measurement path for excessive bubbles

Spikes on flow measurement

Influence from other devices.

- Use the standard EMI ferrites on the sensor cables.

Table 14: Potential troubles and the possible countermeasures

6.2 Troubleshooting with Levitronix

®

Service Software

More detailed error analysis can be done with the Levitronix

®

Service Software. Contact Levitronix

®

for a

sample of the configuration software and the according manual (see reference on title page of this manual).

Loading...

Loading...