Description

10

300554859_002_C0 - 11/2016 - © Leybold

1 Description

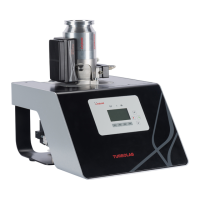

The TURBOLAB pump systems are turnkey vacuum units for pumping vacu-

um vessels to pressures in the high-vacuum range.

1.1 Design

The TURBOLAB pump systems consist of the following components as

standard:

■

Turbomolecular pump TURBOVAC

The TURBOVACs are turbomolecular pumps with lifetime lubricated ceram-

ic ball bearings. A built-in thermal switch switches off the TURBOVAC if the

permissible temperature is exceeded.

■

The frequency converter is integrated into the TURBOVAC and is supplied

with 24 VDC and controlled via RS 485 interface by the TURBOLAB.

■

Backing pump

The TRIVAC is a two-stage rotary vane pump. It is fitted with a gas ballast

valve and an anti-suckback valve. The anti-suckback valve shuts off the

vacuum line to the turbomolecular pump in the event of power failure or

when the unit is switched off.

The SOGEVAC SV 16 D and SV 25 D are single stage, oil-sealed rotary

vane pumps. The anti-suckback valve, gas ballast valve and an exhaust fil-

ter, oil return circuit are integrated functional elements of the SOGEVAC.

The SCROLLVAC pumps are dry compressing scroll pumps.

The DIVAC pumps are two to four-stage, oil-free diaphragm pumps.

Some TURBOLAB pump systems are delivered without backing pump.

■

Vacuum connection between TURBOVAC and backing pump: flexible

stainless-steel line. The connection can be broken, for example to enable

an adsorption trap to be fitted.

■

Frames: Cart with baseplate, mounting column & castors or benchtop

frame with rubber feet.

■

TPU Turbo Pressure Unit

Every TURBOLAB comes standard with the TPU for control, configuration

& monitoring of the turbomolecular pump system.

The backing pump is connected depending on the specific type at X211

(110/230VAC) or at X20 (24VDC) and it starts when the turbomolecular

pump is started.

A safety valve can be connected at X210 (110/230VAC) and this safety

valve is switched in parallel with the backing pump.

The function for the accessory connection is set by default to “Active at

Start Command” and this setting can be changed through Menu →

Accessory → VV Pump.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Loading...

Loading...