Installation

37

300554859_002_C0 - 11/2016 - © Leybold

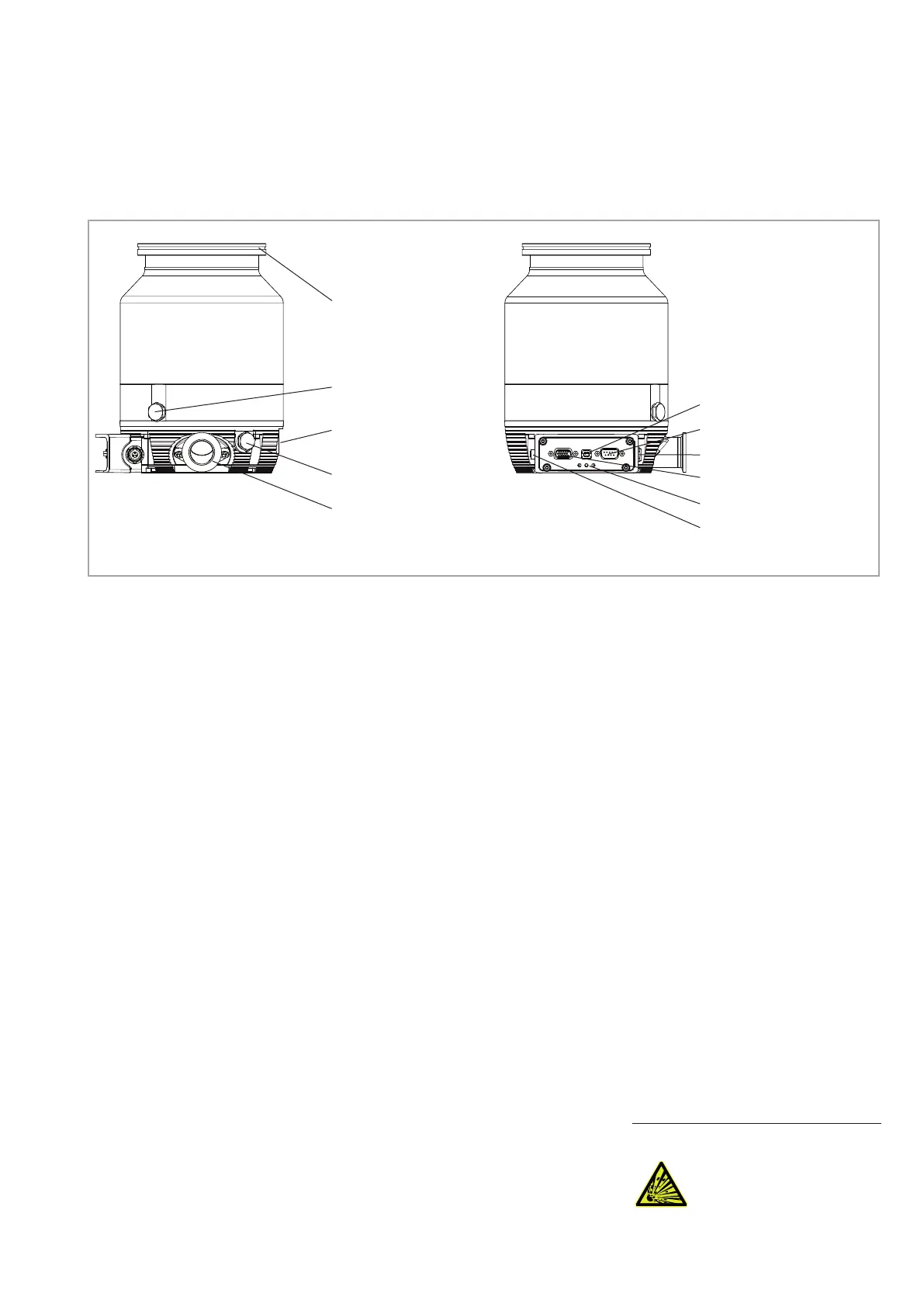

Fig. 3.11 Connections at the TURBOVAC 350/450 i

High-vacuum flange

Venting connection

G1/8“

Mounting surface for

water cooling

Purge gas connection

G1/8“

Forevacuum connection

(is connected)

USB interface X106

RS 485 interface X104

DC input DC IN X10

REMOTE interface X1

LEDs

Accessory connection

DC OUT (M8) X201

3.8 Connect a Power Failure Venting Valve or a Venting Valve

The power failure venting valve (normally open) or venting valve (normally

closed, vents at stop command) vents the pump and the forevacuum line

when the pump is switched off and thus keeps oil vapor from diffusing back

from the forevacuum line. A choke nozzle in the vent port ensures that the

pump is not vented too fast.

The max. permissible pressure in the pump must not exceed 1.4 bar (abs.).

Unscrew and remove the locking screw and the gasket from the venting con-

nection of the TURBOVAC.

Screw in the venting valve and the gasket into the vent connection, then plug

in the corresponding control cable into the X203 accessories connection on

the TURBOLAB. The accessory connection is pre-configured for the vent

valve operation. The vent valve will be triggered depending on the frequency

of the TURBOVAC by default. If you have connected are power failure vent-

ing valve (normally open) you must change the operation output of X203;

Menu → Accessory → Vent → change the operation to Power failure vent

(via the TPU interface); If the pump station losses power then the vent valve

will open.

For an overview of the connections, see fig. 3.14 and 3.15.

If applicable connect the venting gas supply at the valve’s inlet (G1/8“).

To change the venting valve function code go to Menu → Accessory → Vent

(via the TPU interface).

The pressure in the pump must not exceed atmospheric pressure.

Observe Safety Information 0.1.2 to 0.1.5.

WARNING

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Loading...

Loading...