12-4 Check D

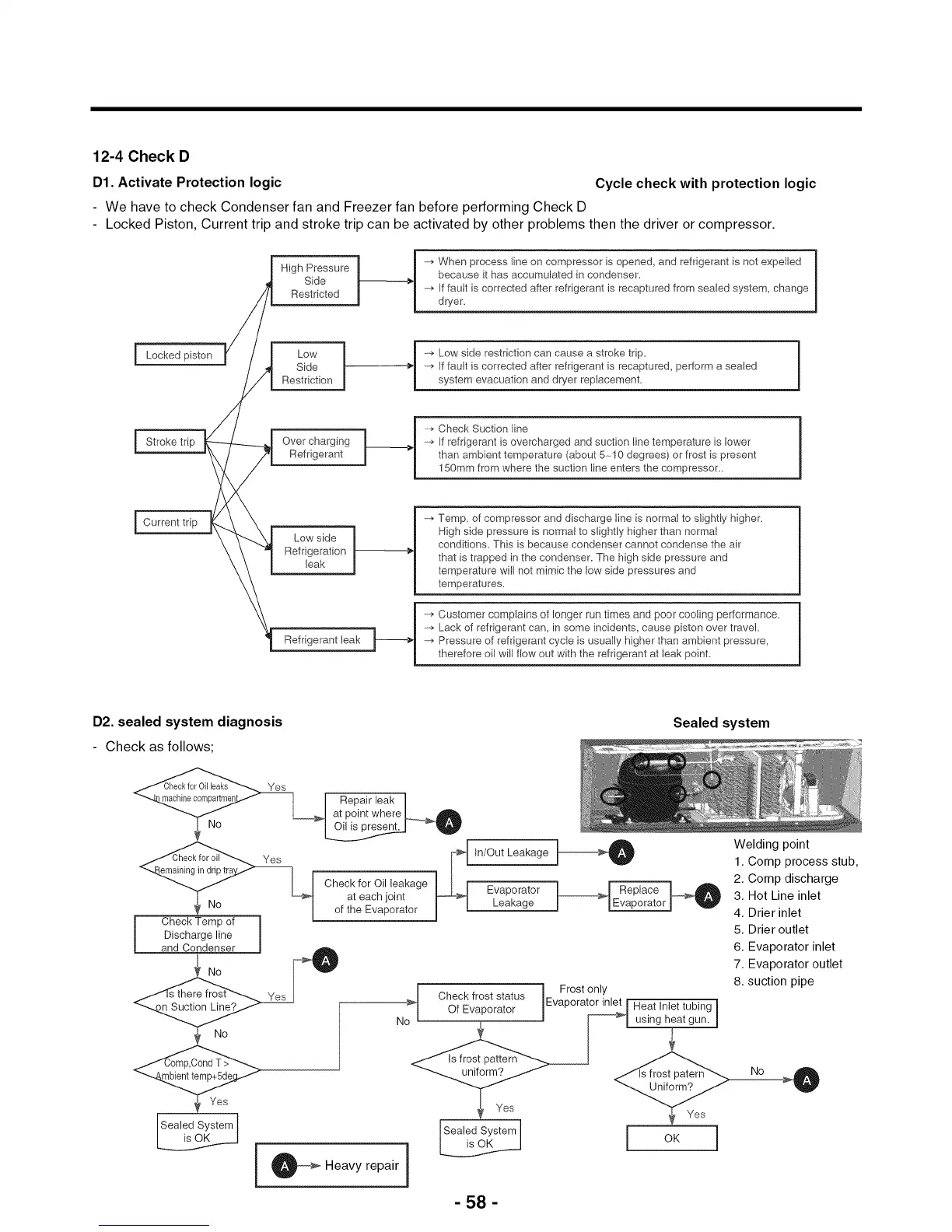

DI. Activate Protection logic Cycle check with protection logic

- We have to check Condenser fan and Freezer fan before performing Check D

- Locked Piston, Current trip and stroke trip can be activated by other problems then the driver or compressor.

High Pressure

Side

Restricted

_-_When process tine on compressor is opened, and refrigerant is not expetled

because it has accumulated in condenser.

_-_ If fauk is corrected after refrigerant is recaptured from sealed system, change

dryer.

I Locked piston

I Stroke trip

I Current trip

Low

Side

Restriction

Over charging ]_I

Refrigerant

Low side ]_

Refrigeration

leak

Refrigerant leak _

_-_Low side restriction can cause a stroke trip.

_-_ If fault is corrected after refrigerant is recaptured, perform a sealed

system evacuation and dryer replacement.

--_ Check Suction Line

---* If refrigerant is overcharged and suction line temperature is lower

than ambient temperature (about 5-10 degrees) or frost is present

150mm from where the suction line enters the compressor..

Temp. of compressor and discharge line is normal to stightly higher.

High side pressure is normal to slightly higher than normal

conditions. This is because condenser cannot condense the air

that is trapped in the condenser. The high side pressure and

temperature will not mimic the low side pressures and

temperatures.

-_ Customer complains of longer run times and poor cooling performance.

--_ Lack of refrigerant can, in some incidents, cause piston over travet.

--_ Pressure of refrigerant cycle is usually higher than ambient pressure,

therefore oit will flow out with the refrigerant at teak point.

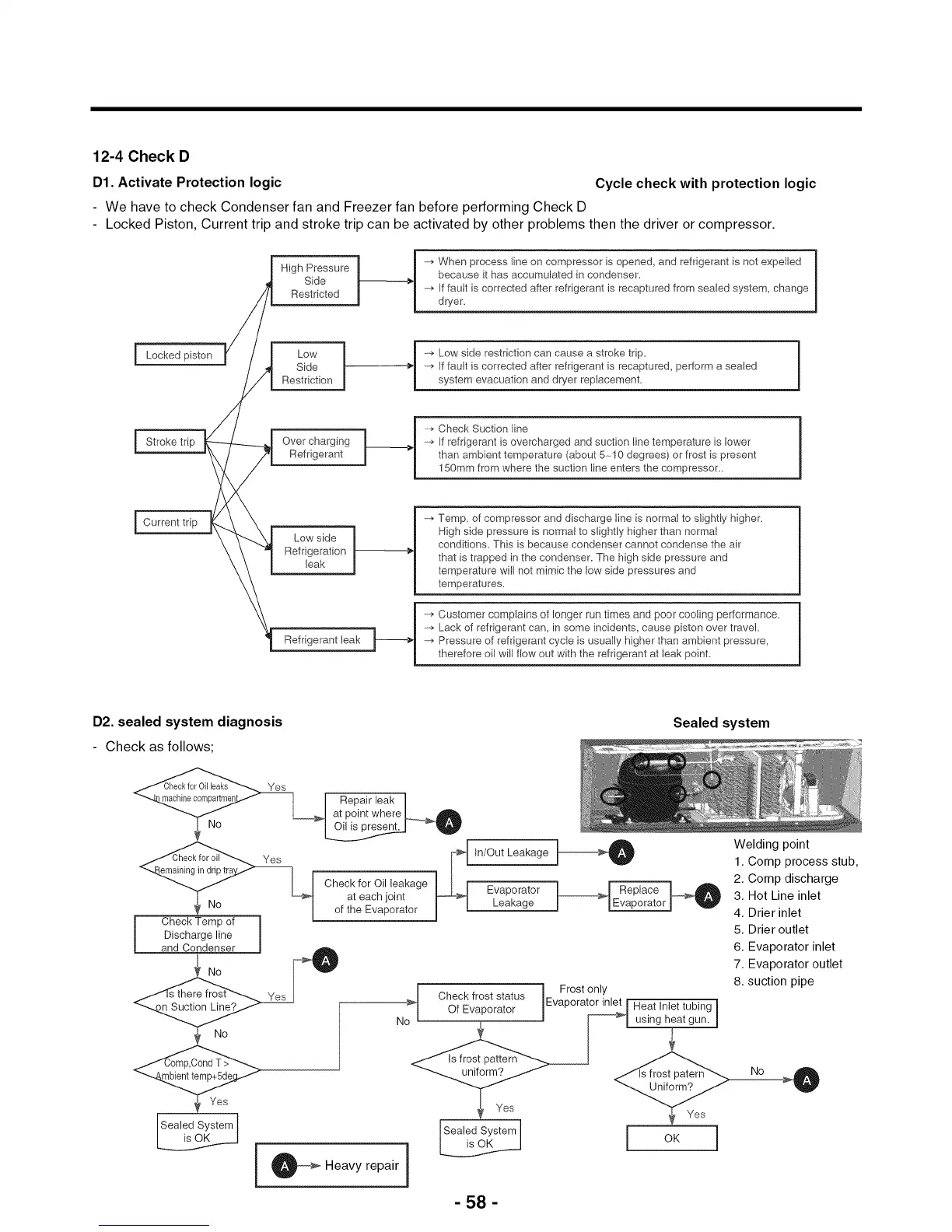

D2. sealed system diagnosis

- Check as follows;

Sealed system

Repair leak

at point where _____

i Check Temp of

Discharge line I

and Condenser I

/

) No

I Sealed System t

i

In/Out Leakage

Evaporator !--_

Leakage

o_ Frost onl_ 1

Check frost status Evaporat

Of Evaporator Heat Inlet tubing

N using heat gun.

IsealedSystemI

_ Heaw repair i

- 58 -

Welding point

1. Comp process stub,

2. Comp discharge

3. Hot Line inlet

4. Drier inlet

5. Drier outlet

6. Evaporator inlet

7. Evaporator outlet

8. suction pipe

Loading...

Loading...