5-6 CHAPTER 5: PNEUMATICS

ALPHA 552

4. MAINTENANCE

The pneumatic system should be regularly maintained in order to ensure the system is powered by

qualified compressed air. We recommend the user to check the F.R.L. combination as instructed below

every week.

1. Check the condensate collector:

The condensate collector is a measure of quality of the compressed air. A qualified air should not

produce any condensate inside the collector.

The collector has an automatic drain plug. When there is no pressure inside the F.R.L. system, the

drain plug is activated by the spring and the condensate released.

For users which always connect the compressed air, a manual draining is needed. Whenever the

condensate is found inside the collector, drain the condensate by pushing the plug upward and

check the humidity control system.

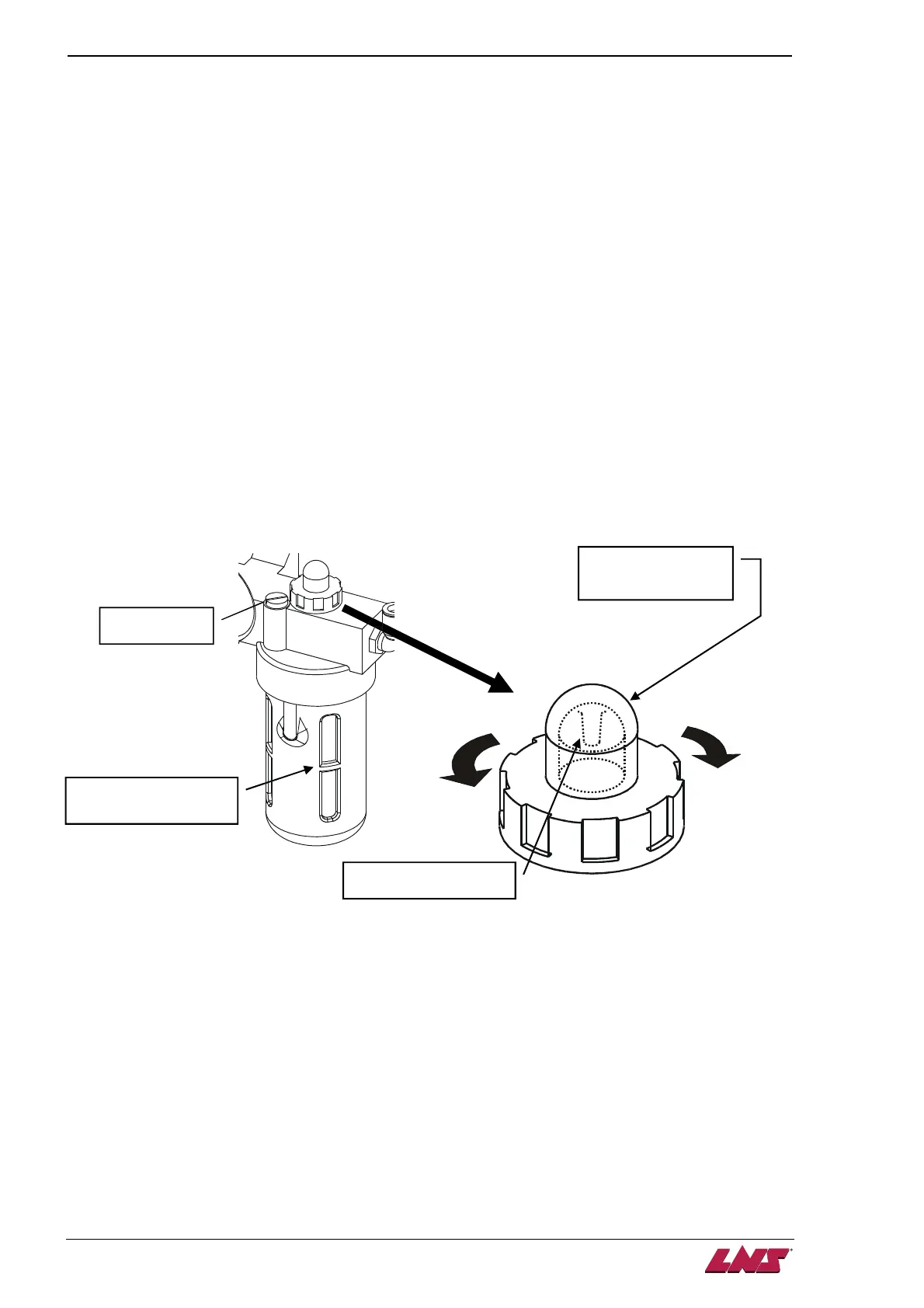

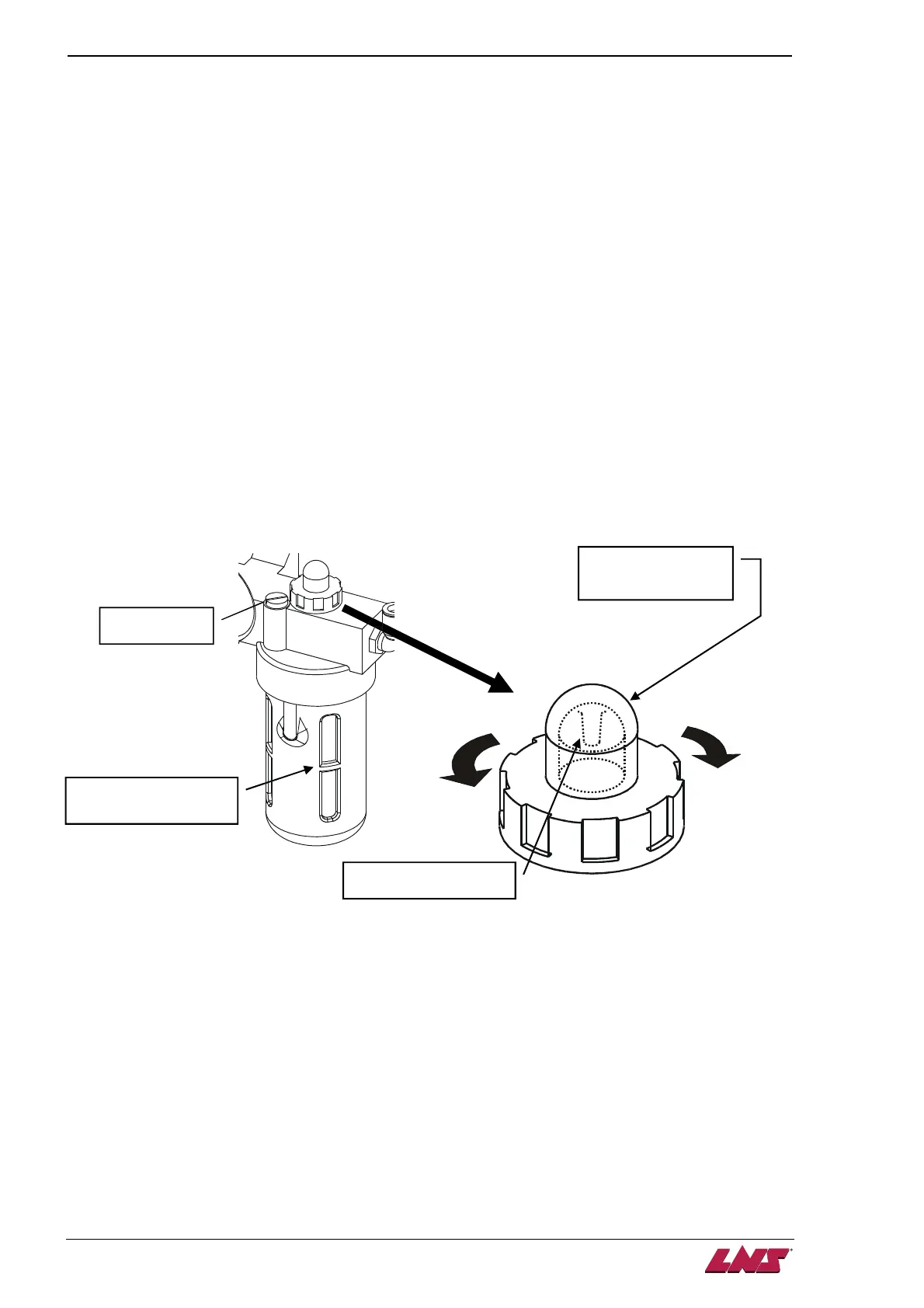

2. Check lubricator:

The oil consumption varies with the bar feed system application of the user. The oil height should

not exceed half height of the cup. When the oil is not enough, follow the procedures below to refill

it. It is recommended to use oil ISO VG 32 only.

• Disconnect the air inlet tube.

• Remove the plug and fill the oil up to the position shown on the figure.

• For the best performance, the oil should drop every cylinder operation. Adjust the fluent with

auxiliary of channel open button. Let the oil drop once after pressing the “channel open”

button for 10 times.

• Connect the air inlet tube and turn air source on.

Oil refill plug

Keep the oil level

Fluent monitoring

window

Oil dribbling nozzle

DECREASING

INCREASING

Loading...

Loading...