8-8 CHAPTER 8: OPERATION

ALPHA 552

5. OPERATION PARAMETERS

Please read the safety instructions provided at the beginning of this manual before

handling the following devices.

The operation parameters are most frequently changed parameters for controlling the barfeeder when it’s

in AUTOMATIC mode. All the operation parameters could be changed according to the machining

requirement. To achieve the best performance, the operator is strongly recommended to read this chapter

before proceeding to any modification.

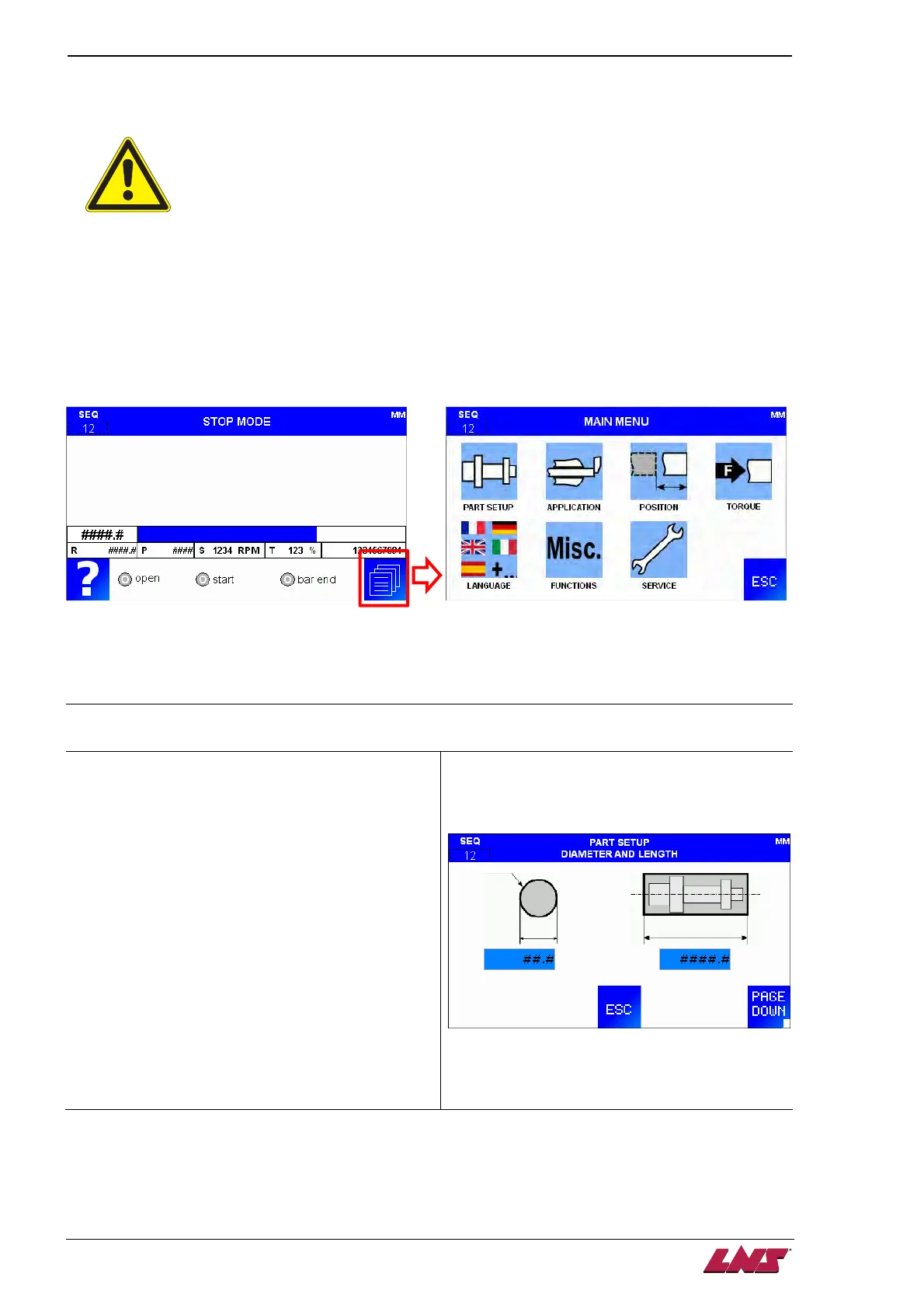

5.1. Accessing and editing parameters

After selecting the operation parameters the following screen will be displayed:

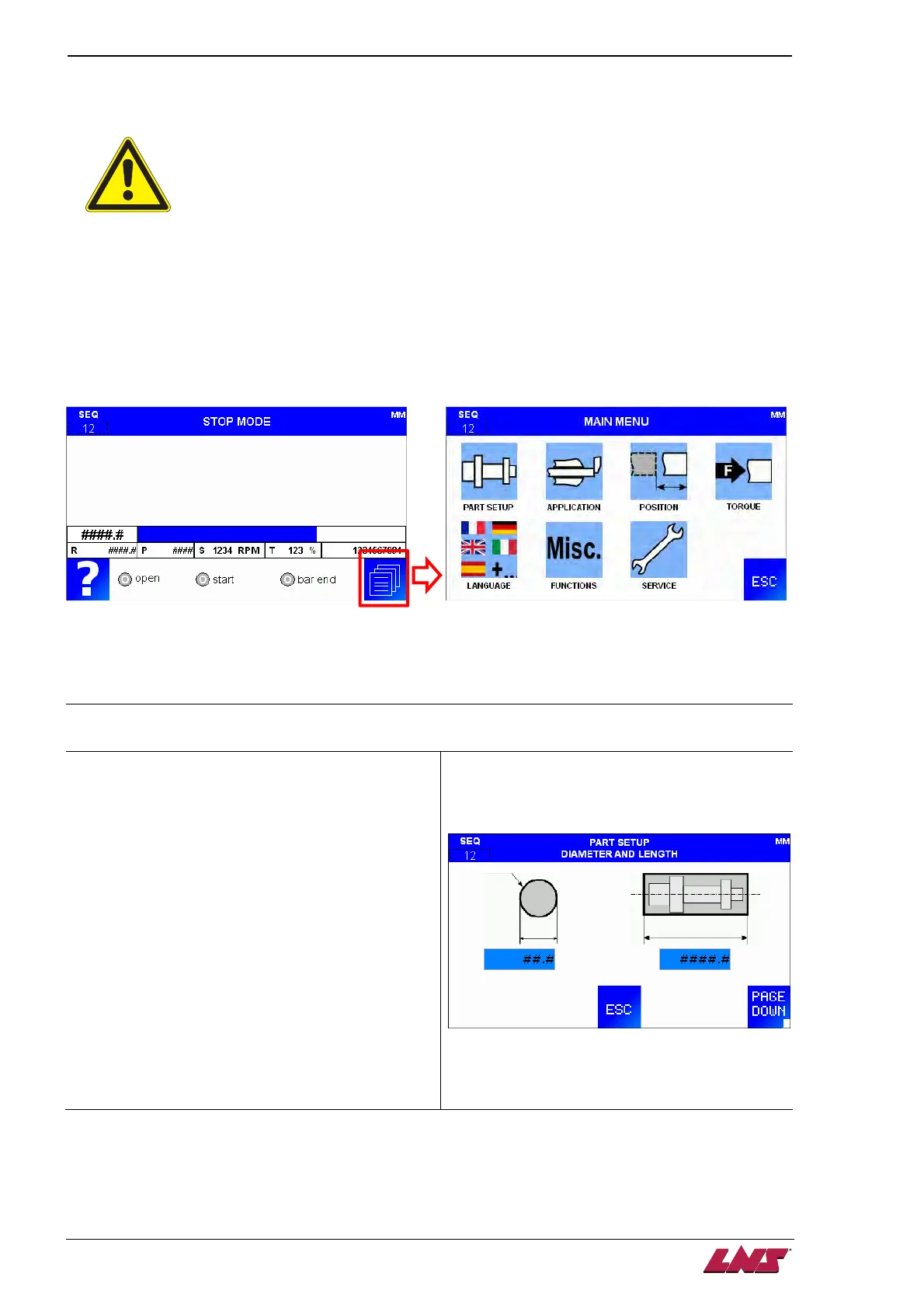

5.2. Part setup parameters

Part setup: Diameter & Length

Bar diameter

This parameter decides the basic pushing force.

Enter the bar stock diameter currently loaded inside

the channel.

.

Part length

Overall feeding length needed for making a part.

Part length plus cut off tool width.

This value is for calculation of BAR END position

and timing of sending CYCLE START signal. The

barfeeder will not stop at this distance during

feeding. The lathe must place a stopper inside the

lathe for positioning.

Example: If the part is 100mm and the cut off tool

width is 3mm. The value entered here

is 100+3=103.

Loading...

Loading...