BOTTOM CUTTER

Before you open the safety doors on the

planer, ensure that the power is switched

off and that the cutters are not rotating. Use

protective gloves, particularly when you need

to loosen screws that are tightly fastened, or

when you are tightening screws (see warning

instructions). Beware of the planer knives. It is

extremely easy to cut yourself on these, even

with the slightest touch.

The bottom cutter is xed to the planer table on the

planer's infeed side. Two planer knives are moun-

ted in two of the bottom cutter's tooling slots on

delivery (planer knife 410 mm (16") HSS, item no.

7000-002-8410). Another two planer knives, or

molding knives can be mounted in the two empty

tooling slots.

SETTING THE BOTTOM CUTTER'S CUT

The cut of the bottom cutter is set using a lever

(211). Locking is done using a lever (224).

The normal cut on the bottom cutter is 2 mm

(8/100").

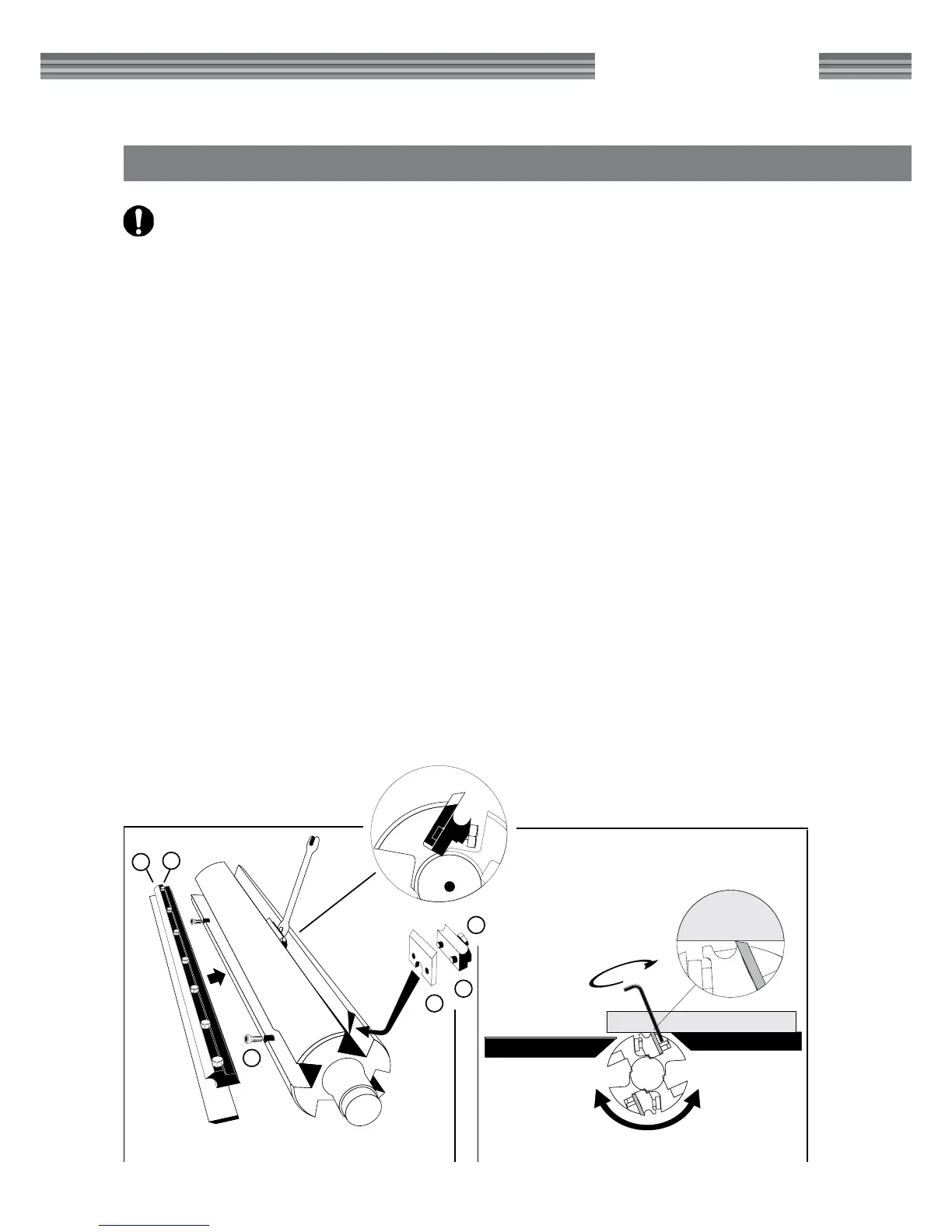

DISASSEMBLING THE PLANER KNIFE

The planing knife is disassembled by loosening the

chip breaker's (A) lock screws (B) and then unscre-

wing the planing knife with adjuster screws (C).

GRINDING THE PLANING KNIFE

Always grind the knives in pairs, so they are the

same height, min. 15 mm (.600"), otherwise vibra-

tions could occur in the cutter. The grinding angle

must be 38 degrees. You can order a grinder from

Logosol for sharpening molding and planing knives

(Tormek Grinder, item no. 7010-000-1000, Jig for

planing knives, item no. 7010-000-1005).

ADJUSTING THE BOTTOM CUTTER'S

PLANING KNIFE

The bottom cutter's planing knife must be set so

that it is on the same level as and in line with the

planer table.

• Loosen the chip breaker's lock screws (B) that

are found in the groove between the chip brea-

ker (A) and the cutter using a 10 mm (4/10")

key (supplied). After this the knife can be raised

or lowered using the two adjustable screws

(4 mm socket head) (C) that are recessed by

the cutter's keyway. Use a 4 mm socket head

screw (supplied). The knife must stick out 1 mm

(.040") from the cutter body to align with the

molding knife from Logosol.

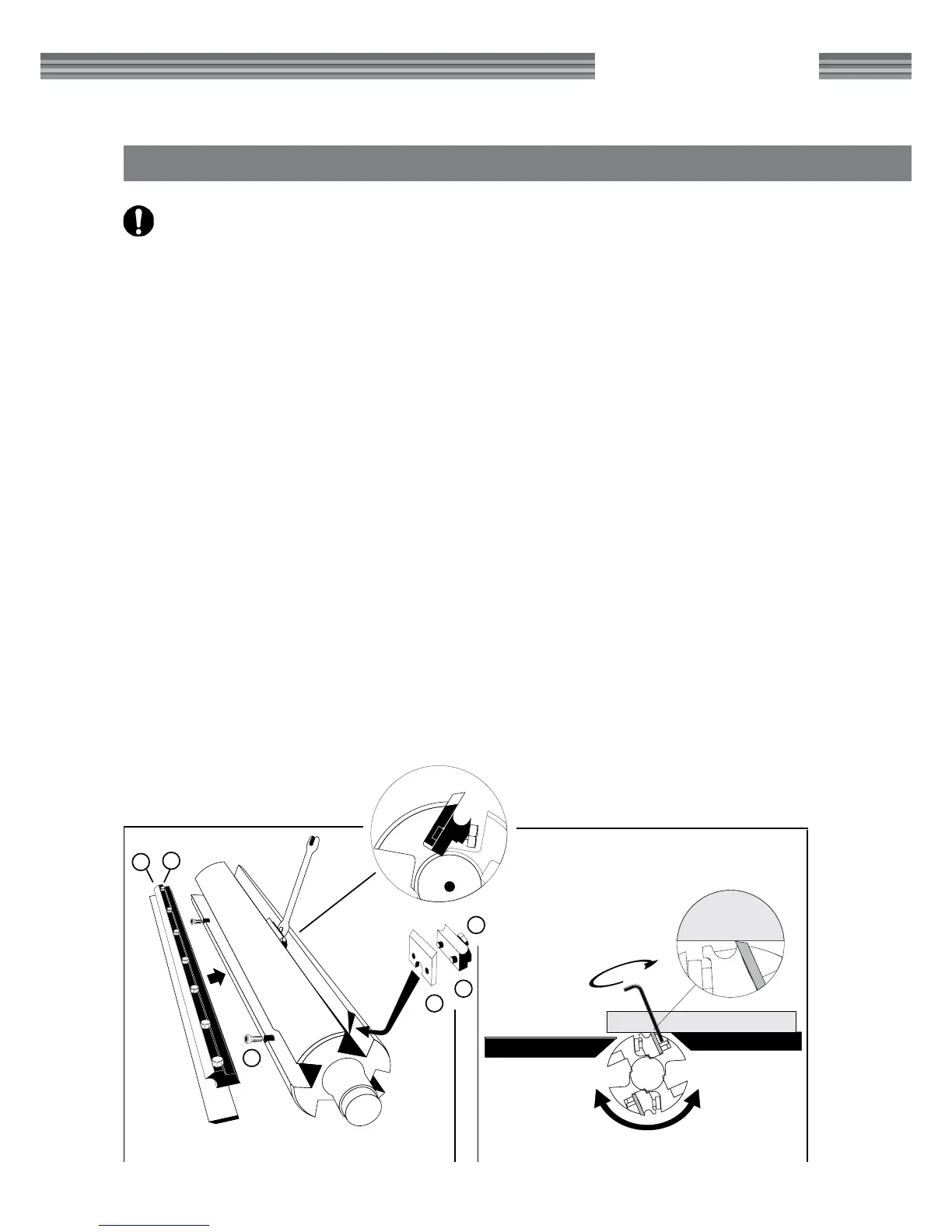

• Check the level of the knife by placing a bit of

planed edging on the planer table behind the

cutter. The cutter's knife should then touch the

edging (see image below). Another method is to

A

B

C

D

E

F

Loading...

Loading...