PREPARATIONS

Certain parts are not assembled on delivery for

transport and packaging reasons.

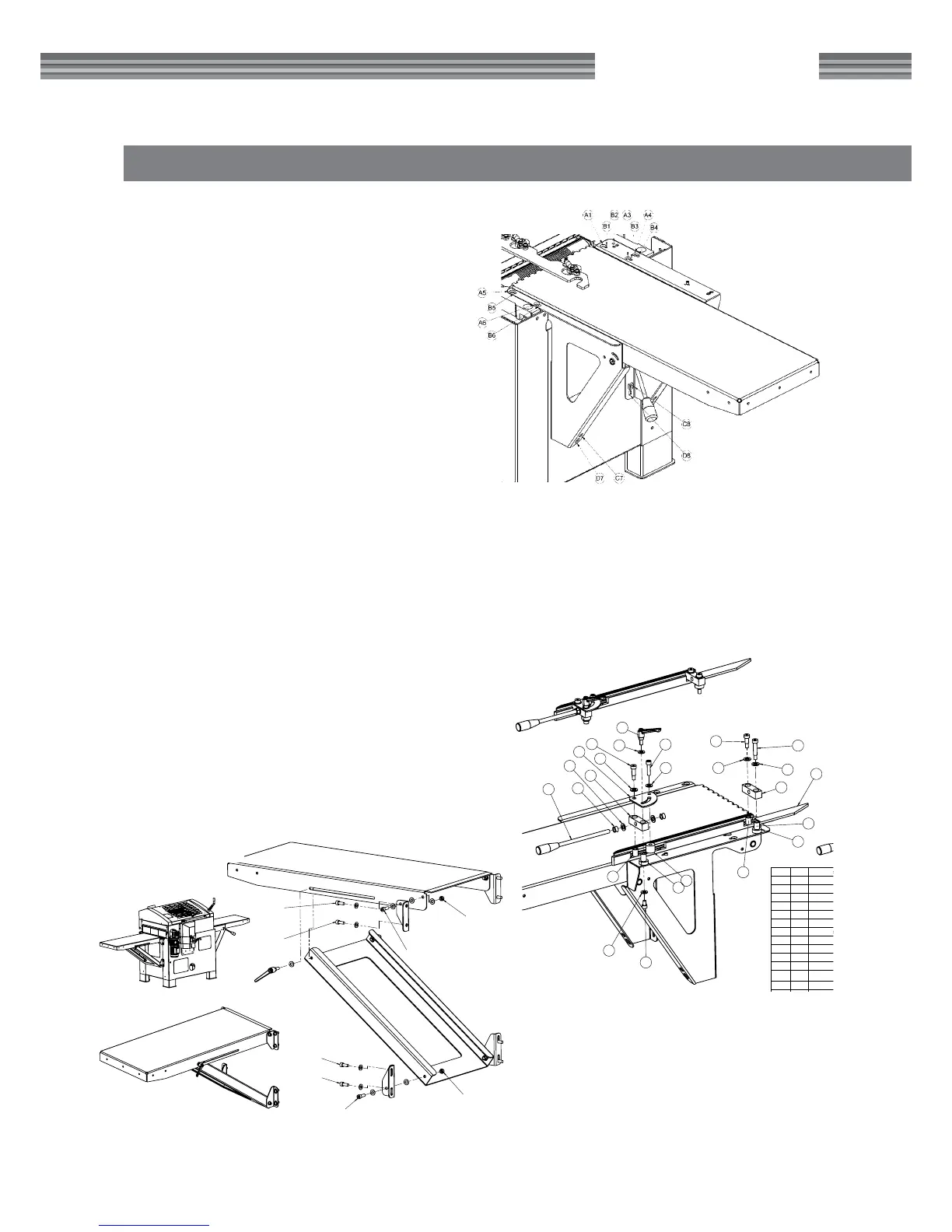

1. Assemble the control panel in place with the

arm where the cabling goes, (232), (251).

2. Assemble all safety doors.

3. Assemble the infeed table (212). [Figure 1]

• Screw down all adjustable screws (B) in the

bottom.

• Insert all screws (A) tighten by hand.

• Insert the adjustment screws (C) and adjust

the table so it is straight.

• Adjust exactly: The highest position of the

infeed table must be on the same level as the

cast machine table. Check with a long, straight

fence rail.

• Adjust the height of the table so that it

touches the cast iron table with the adjustment

screws (B) and tighten the holding screws (A).

• Check the table angle and table height and

insert the table xture’s bottom lock screws (D)

which are fastened using nuts on the inside of

the chassis.

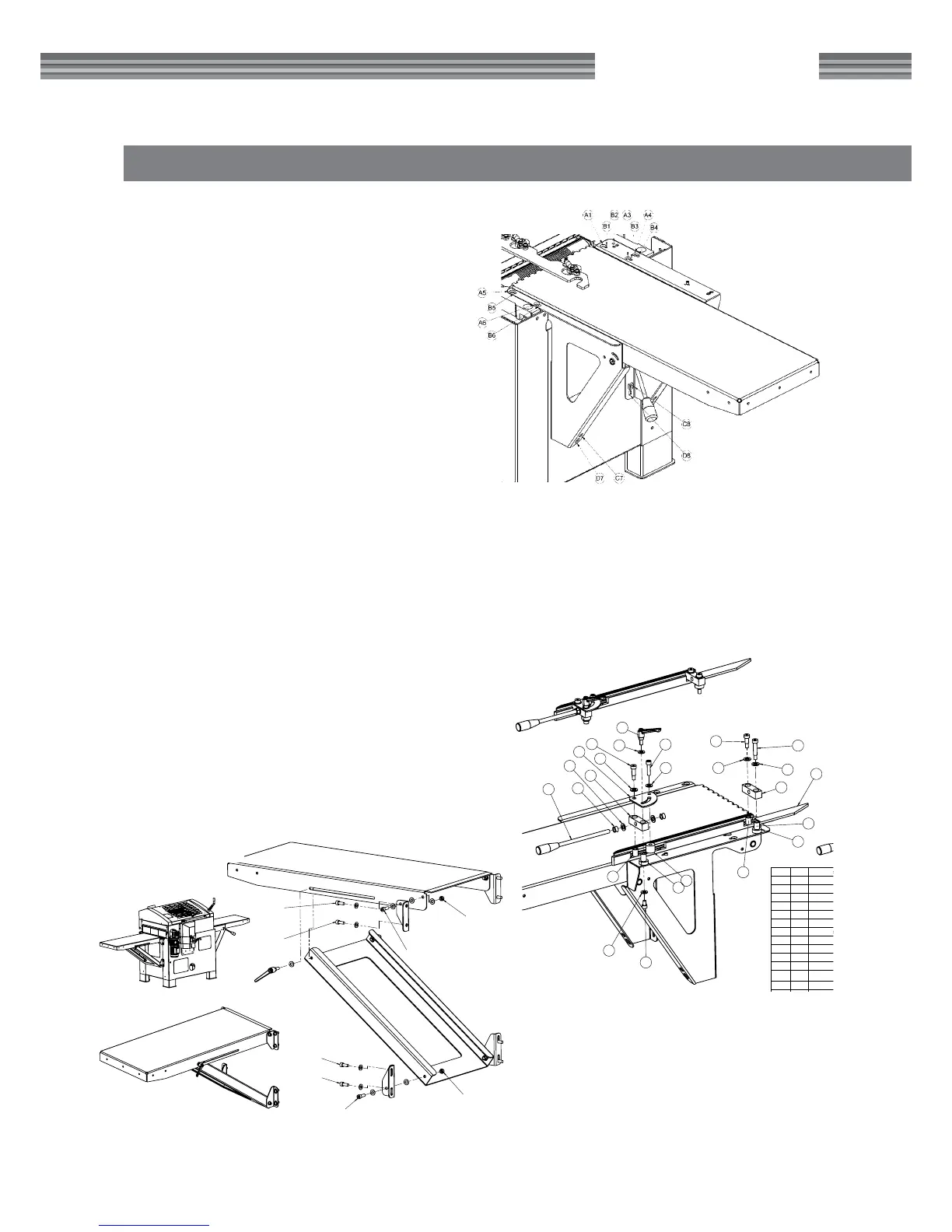

4. Assemble the outfeed table (253). [Figure 2]

5. Assemble the side fences [Figure 3]

6. Connect the planer/moulder to the chip extrac-

tor.

7. Before the planer/moulder is connected to the

electrical circuit, check that all cutters can rotate

freely, and that all parts are xed.

Hole pattern key:

A: Holding screws for the infeed table.

B: Holes for accessing the adjusting screws where the screw

head lies under the table xture.

C: Threaded hole for adjustment screws for setting the table angle.

D: Hole for lock screws.

E: Fixing point for adjustable side fence. A double hole pattern

means that the fence can be placed in an outer or inner position

Figure 1.

PH360

M10-30mm

M10-25mm

M10-25mm

M10-30mm

M10

M10

M10-25mm

M10-25mm

19

39

27

16

14

38

22

22

22

43

42

13

23

15

17

16

14

24

16

25

42

41

26

42

16

Loading...

Loading...