TOP CUTTER

Before you open the safety doors on the

planer, ensure that the power is switched

off and that the cutters are not rotating. Use

protective gloves, particularly when you need

to loosen screws that are tightly fastened, or

when you are tightening screws (see safety

instructions). Beware of the planer knives. It is

extremely easy to cut yourself on these, even

with the slightest touch.

SETTING THE CUT OF THE TOP CUTTER

The planer thickness is set using the planing table

crank (189). The set thickness can be read on the

indicator (109) on the machine stand. The indicator

can be calibrated. Plane some wood and adjust the

top cutter until you get the correct height. Release

the green cover (168). The ring above the indicator

has a stop screw. Turn the ring so that it shows the

planing height that has been planed.

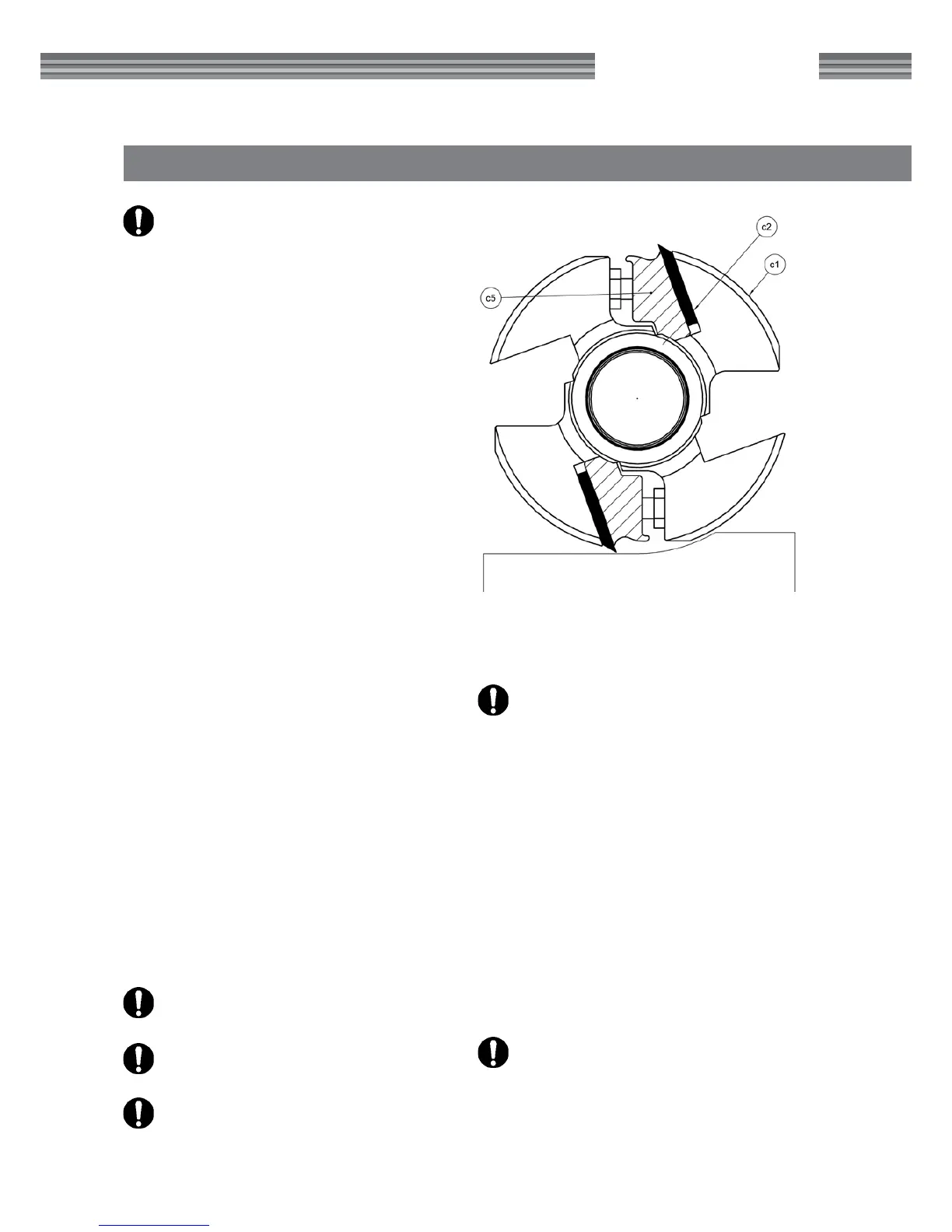

The top cutter is xed to the chassis and hung at

both ends. Two planing knives are mounted in two of

the bottom cutter's tooling slots on delivery (planer

knife 510 mm (20") HSS, item no. 7000-002-8510).

Another two planing knives, or molding knives can be

mounted in the two empty tooling slots.

Always set the top cutter uppermost to reduce any

slack in the threads. If the top cutter needs to be

lowered, lower it half a rotation too low and then

raise it into the correct position. Once you have the

top cutter set at the correct height, you can lock it

in position with the handle to the right of the feed

motor assembly.

DISASSEMBLING, ASSEMBLING AND

GRINDING PLANING KNIVES

See above, under the Bottom cutter section. Exceptions:

The minimum height of the planing knifes are different.

Make sure you´re using the right Setting Block.

After adjusting or replacing planing knives:

Check that no tools have been left in

the planer.

Check that all screws have been sufciently

tightened.

Check that the cutters can rotate freely before

the safety doors are closed.

Do you remember the warning instructions on

pages 4-5?

ADJUSTING PLANING KNIVES

Adjust the planing knives so that they are the same

level and protrude 1 mm (.040"). This is done using

an aluminum adjustment block (item no. 7500-000-

1020), found in the component packaging on the

planer table when the planer/moulder is delivered.

Loosen the chip breaker's lock screws slightly, and

place the adjustment block over the knife. Adjust

the knife up or down until the knife brushes against

the block when it passes above the knife. (The pla-

ning knife protrusion can also be adjusted using a

magnetic adjuster for the top cutter, item no. 7500-

001-0050. See the instructions enclosed with the

magnetic adjuster.)

Tighten the lock screws that lock the knife,

counter-clockwise. Start by tightening care-

fully. Move from the sides in move towards the

middle, retightening them later.

Loading...

Loading...