GENERAL

• Check the molder/planer as soon as you receive

it. Report any transport damage to the transport

company immediately.

• LIFT THE PLANER/MOULDER using a fork-lift or

pallet jack.

• When replacing spare parts, use only original

parts and note that anything electrical must be

assembled by a qualied electrician.

APPLICATIONS

The planer/moulder can be used for planing/molding

and planing wood, chipboard, board, etc.

Hard materials such as chipboard, teak, MDF, etc.

require hard carbide tools, see the Logosol-Toolbox

catalogue.

The planer/moulder is designed for indoor use, with

temporary outdoor use.

ENVIRONMENTAL REQUIREMENTS

The temperature in the premises should be above

freezing, unless special measures are taken.

Ventilation in the premises must be mechanical, and

of a good standard.

The planer/moulder must be connected to a chip

extractor, which is approved according to CE-stan-

dards, see page 10.

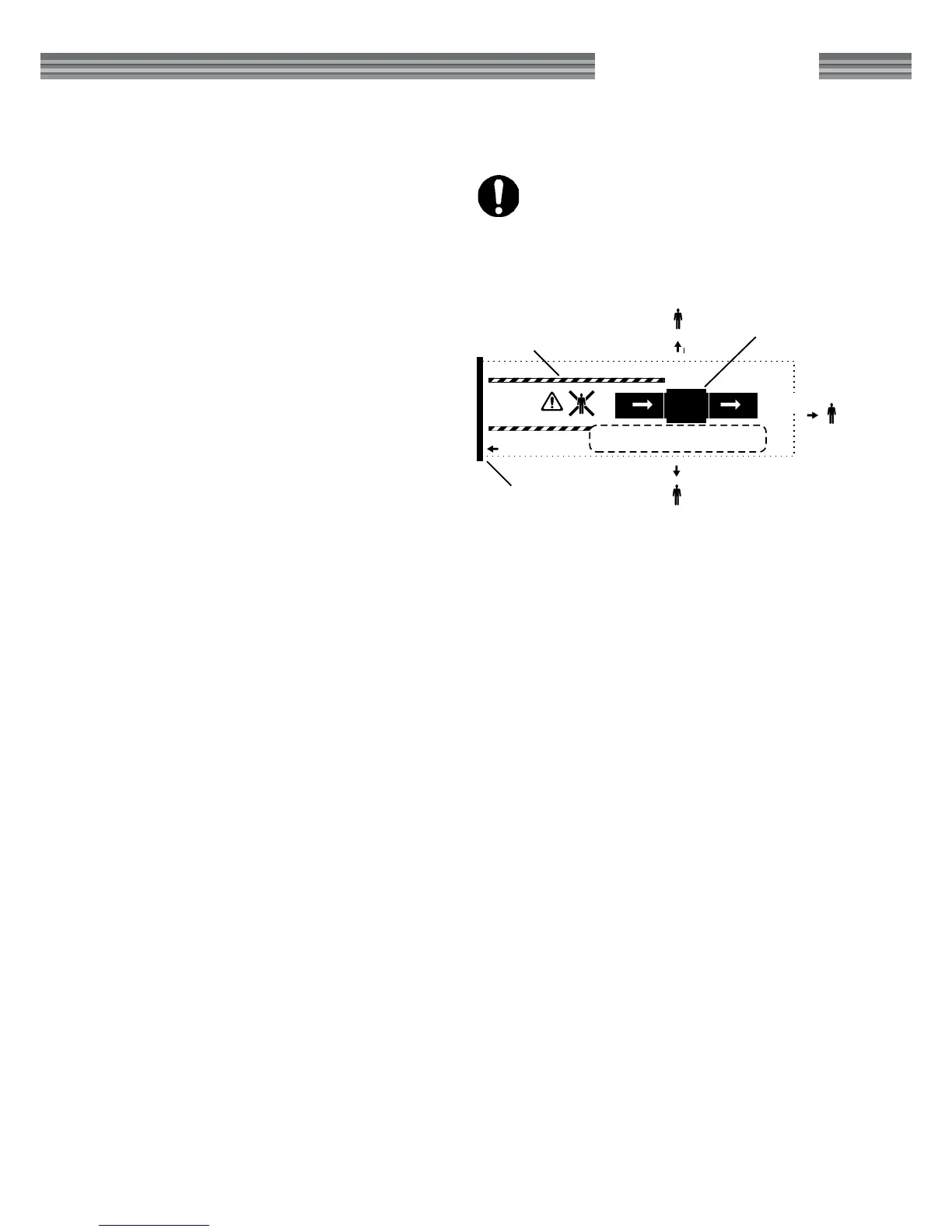

SAFETY DISTANCE

Other than the operator, no-one should

be within 3 meters (10 foot) of the planer/

moulder's sides or 8 meters (26 foot) from

the in and outfeed sides during operation.

Mark a limit that prevents anyone acciden-

tally wandering into the risk area.

TIPS: An extended infeed table is practical to use,

and prevents anyone coming into the risk area.

The operator's work area

The barrier behind

the infeed side

Demarcation

PH360 with in and

outfeed table

Risk area

3 m

(10 ft)

3 m (10 ft)

6 m (20 ft)

Max 8 m (26 ft)

Loading...

Loading...