18

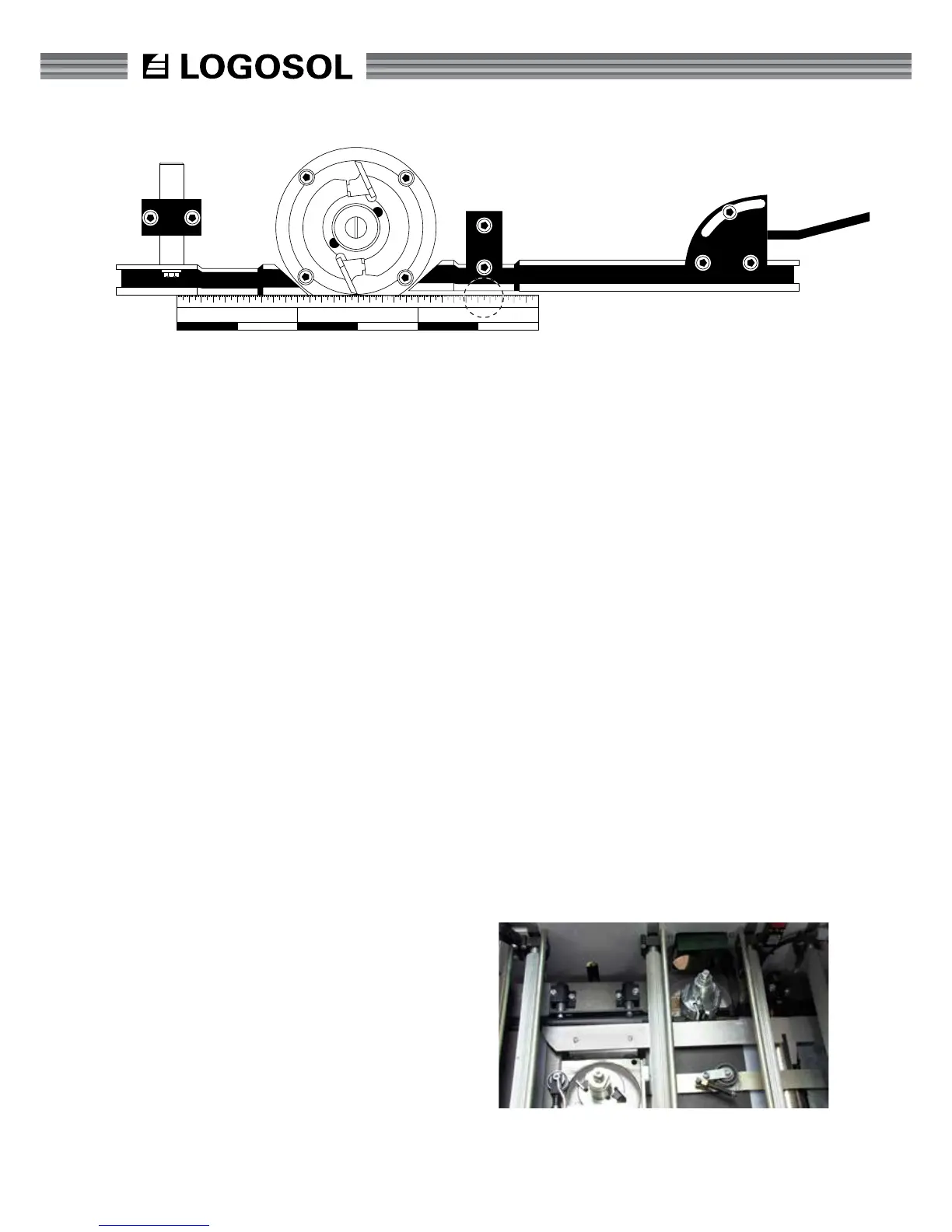

ADJUSTING THE FENCE BY CUTTER 2

In general

The front side fence has a double set of holes for

assembly. It can therefore be assembled in two

basic positions. When the TB90 system is used, the

fence will be tted in the pair of holes on the right,

as seen from the infeed side (see assembly of side

fence, page 7). When cutters with larger diameters

are used, the fence can be moved to the left pair of

holes, so that the stroke length is sufcient.

The xed cutter has two fences, the front (62) and

the back fence (54). The front fence controls how

much the cutter cuts, and the back fence works as a

support for the workpiece when it has passed cutter

2 and is ready to be worked by cutter 3.

Both fences must be in line with one another, but

offset in parallel so that the front fence is slightly

more to the right (see g.). In this way, the back

fence will support the workpiece once it has been

cut by cutter 2 (the workpiece is slightly smaller then).

The fence is xed by socket head screws in the fence

holders (55) according to g. The screws that lock the

fence in the horizontal direction are 13 mm (5/10")

hexagonal screws and sit in the fence's U prole. In

addition, there are micro adjustments on the fence.

When the hexagonal screws are loosened slightly,

the knob for micro-adjustments can be turned. If the

angle of the fence needs to be adjusted, both the

hexagonal and socket head screws must be loosened.

INSTALLATION OF SIDE FENCES

Method 1:

• Insert the rst fence inwards, for minimal cut-

ting. Add a straight aluminum fence rail tight

against the fence. Adjust the fence using the le-

ver until the loose fence rail touches the cutter’s

plane diameter (the outer rotating line) as it lies

against the rst fence.

• The plane diameter that is inline with the back

fence is where you need to measure to, the

cutter’s plane diameter that is higher than 30

mm above the table height is unimportant here.

• Align the back fence along the guard rail, which

is still tight against the rst fence and tighten it.

The cut is now 0 mm. The rst fence, cutter and

back fence are fully inline, and the rst fence

controls the angle through the machine.

• Remove the fence rail and all loose tools from

the machine.

• Move the rst fence back to the required cut

and lock it using the tie-back knob. (Around 2

mm is usually a suitable cut for the rst cutter.)

Method 2:

• The back fence is pulled in so that it is not used,

and is xed there. (Check that the cutter can

rotate freely.)

• Position the front fence so that the required cut

depth is obtained and the fence stands straight.

Tighten the screws that x the fence.

• Close the safety doors and take the measures

required to start the planer/moulder (see page 4).

• Start the bottom cutter, both side cutters and

the feeder and feed in a test piece of approx. 1

meter (3 ft). Stop the planer/moulder just as the

board reaches the moveable cutter (cutter 3).

• Drive the back fence towards the planed part of

the board.

• Check that the test piece is lying against both

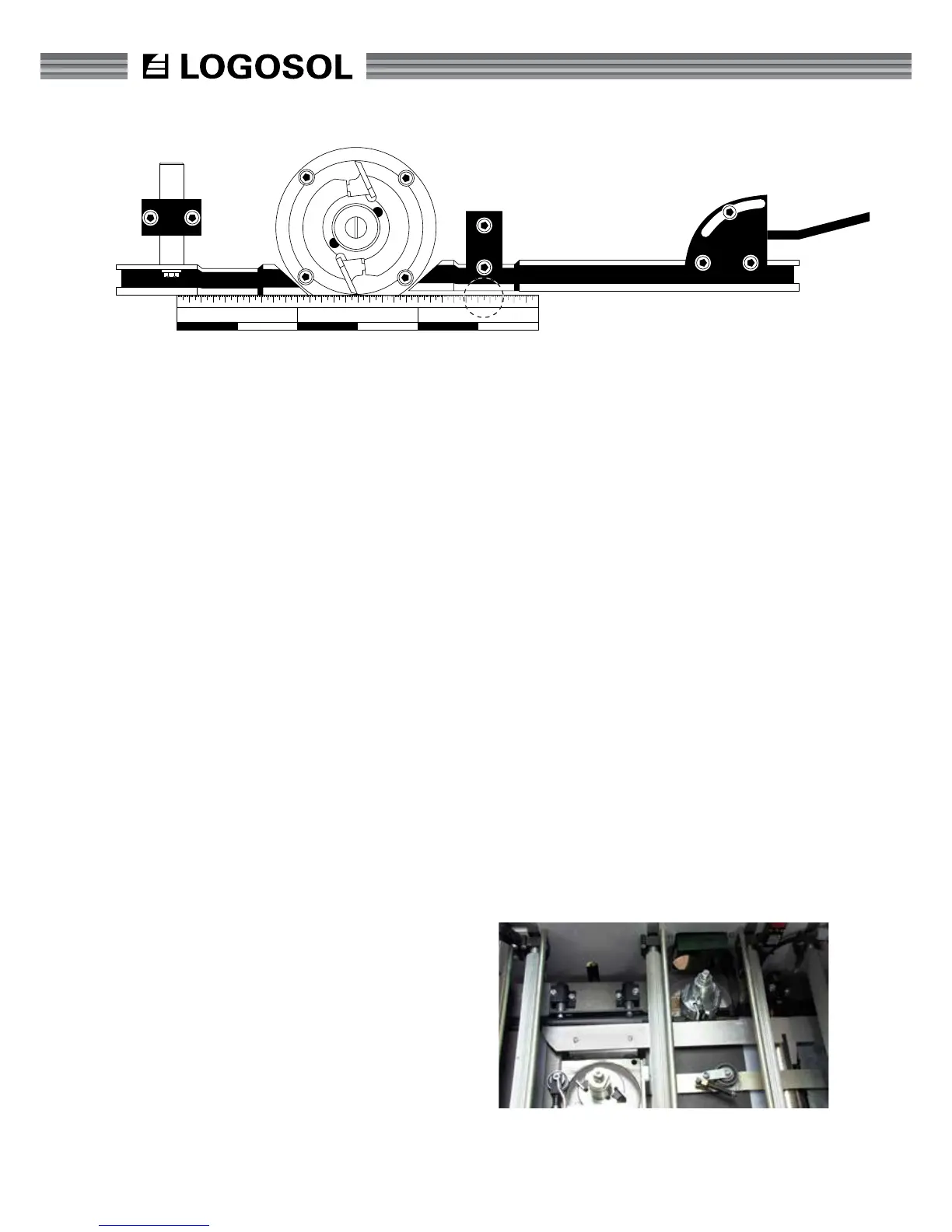

Installation jig for adjusting fences.

Loading...

Loading...