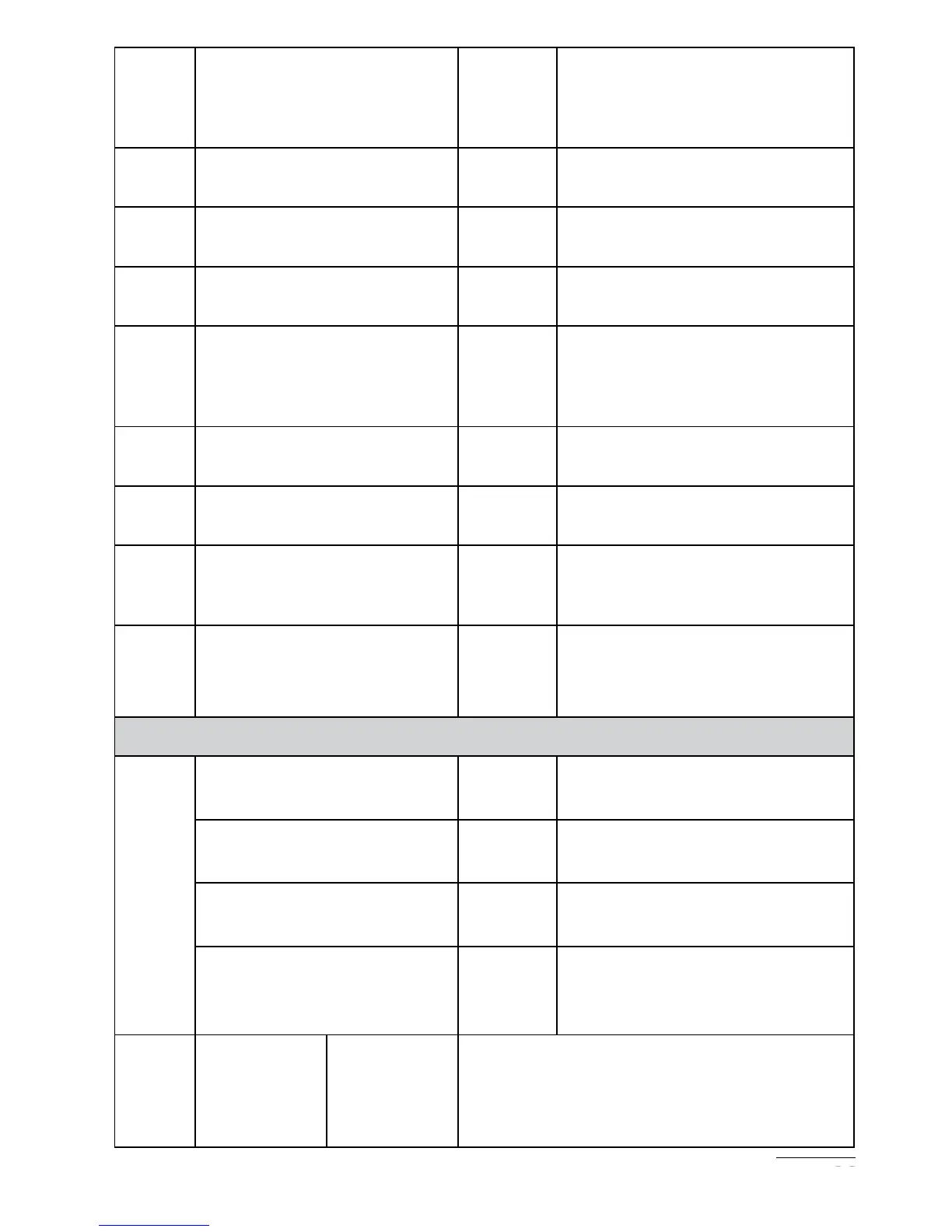

Gsnb

Number of PID sets for

“Gain Scheduling” from

the set point value

2

2: 2 PID sets

3: 3 PID sets

4: 4 PID sets

Gl12

Switching level for PID1

and PID2 sets

0.0

MIN...MAX 3)

Gl23

Switching level for PID2

and PID3 sets

0.0

MIN...MAX 3)

Gl34

Switching level for PID3

and PID4 sets

0.0

MIN...MAX 3)

Gset

Selection of the constant

PID set

pid1

pid1: PID1 set

pid2: PID2 set

pid3: PID3 set

pid4: PID4 set

sTlo

Lower threshold for auto-

tuning

0.0

o

C

MIN...MAX 3)

sTHi

Upper threshold for auto-

tuning

800.0

o

C

MIN...MAX 3)

fdb

Stepper control algorithm

type

no

no: algorithm without

feedback

yes: algorithm with feedback

i#fl

State of valve when auxi-

liary input error

u_Cl

u_Cl: valve closing

u_Op: valve opening

u_no: valve position

unchanged

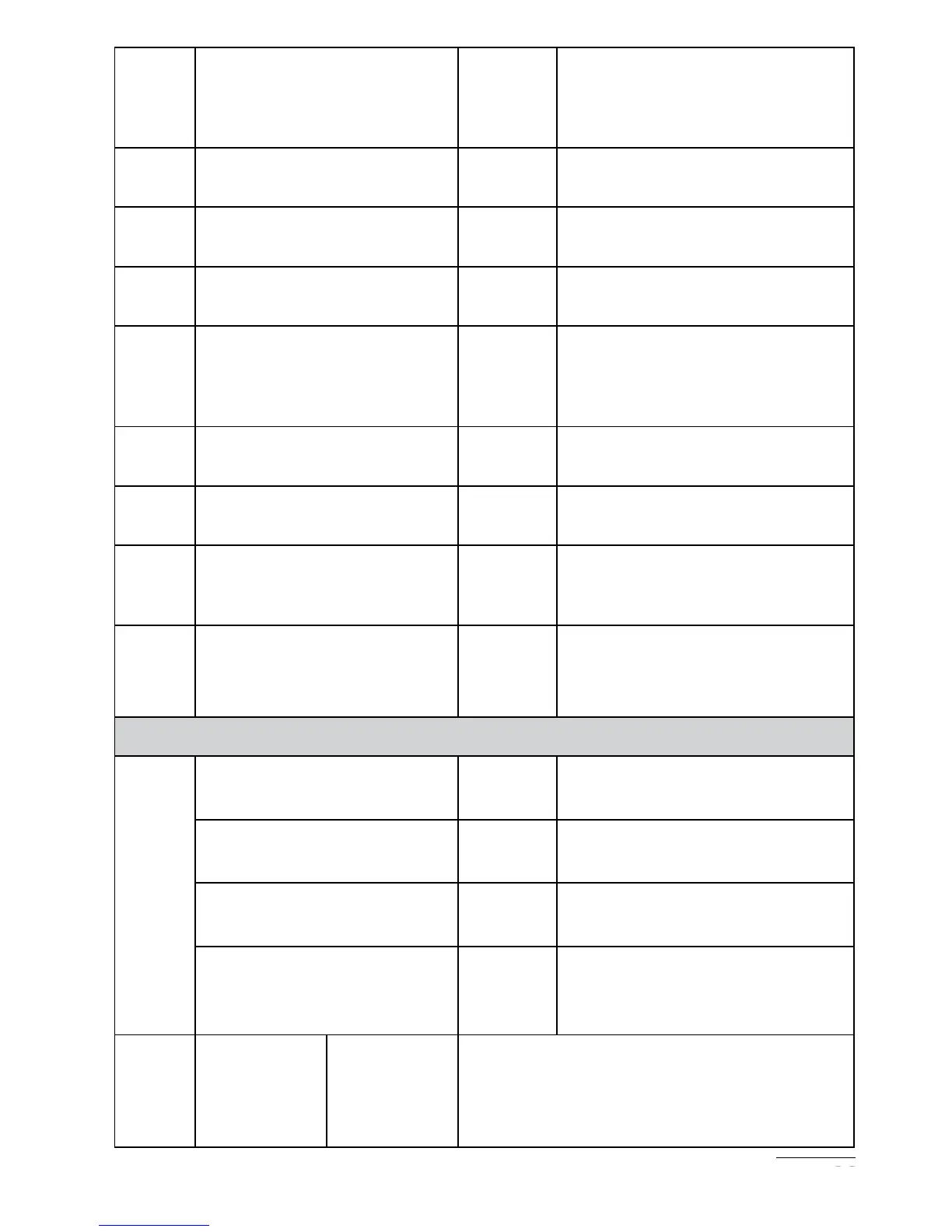

pid – PID parameters

pid1

pb Proportional band 30.0

o

C 0.1...550.0

o

C

(0.1...990.0

o

F)

ti Integration time

constant

300 s 0...9999 s

td Differentiation

time constant

60.0 s 0.0...2500 s

y0 Correction of the

control signal,

for P or PD control type

0.0 % 0...100.0 %

pid2 pb2

ti2

td2

y02

Second set

of PID pa-

rameters

as PB, TI, TD, Y0

Loading...

Loading...