7 Troubleshooting

46 MAGNETEK HPV1000 AC Elevator Drive Technical Manual

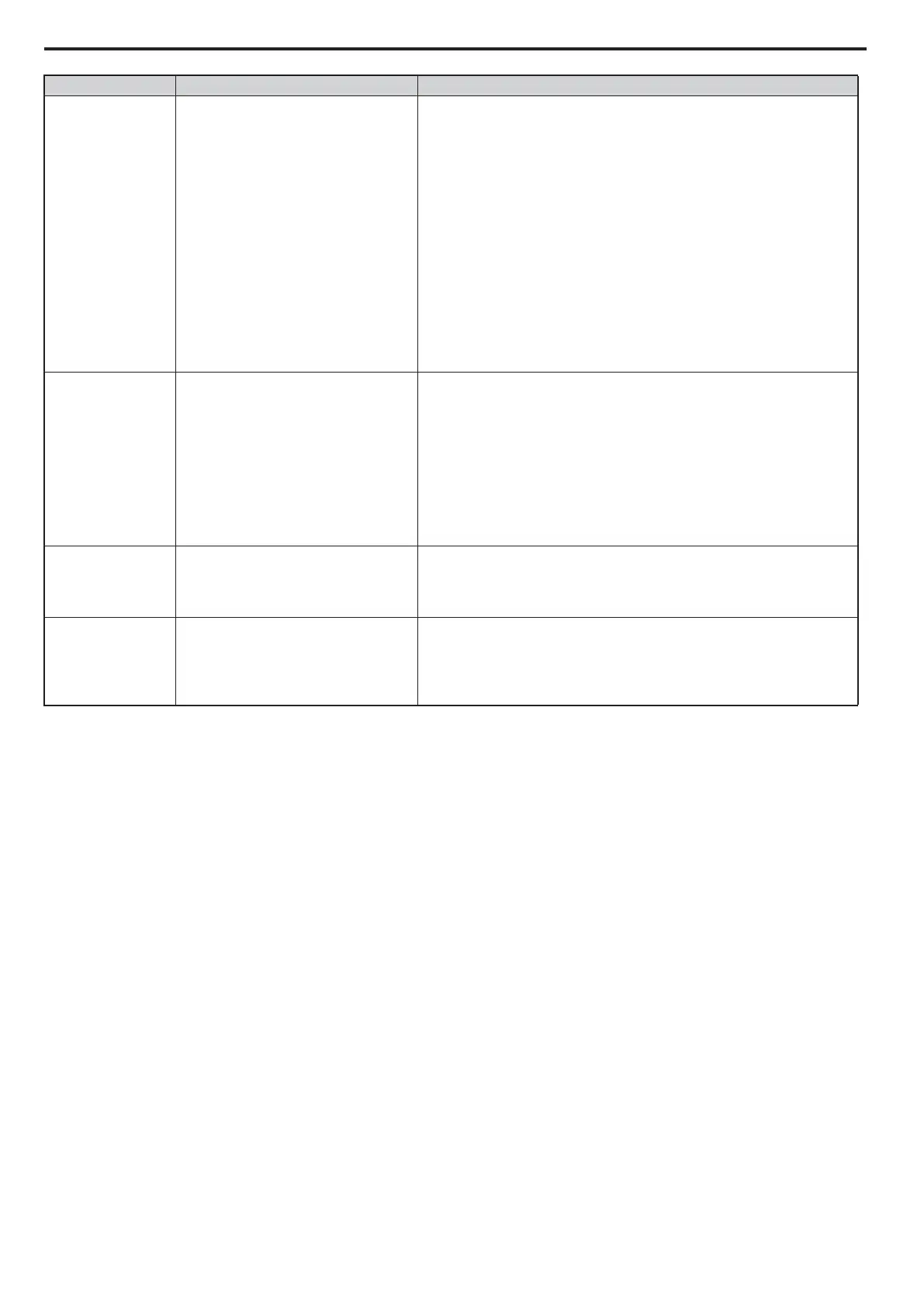

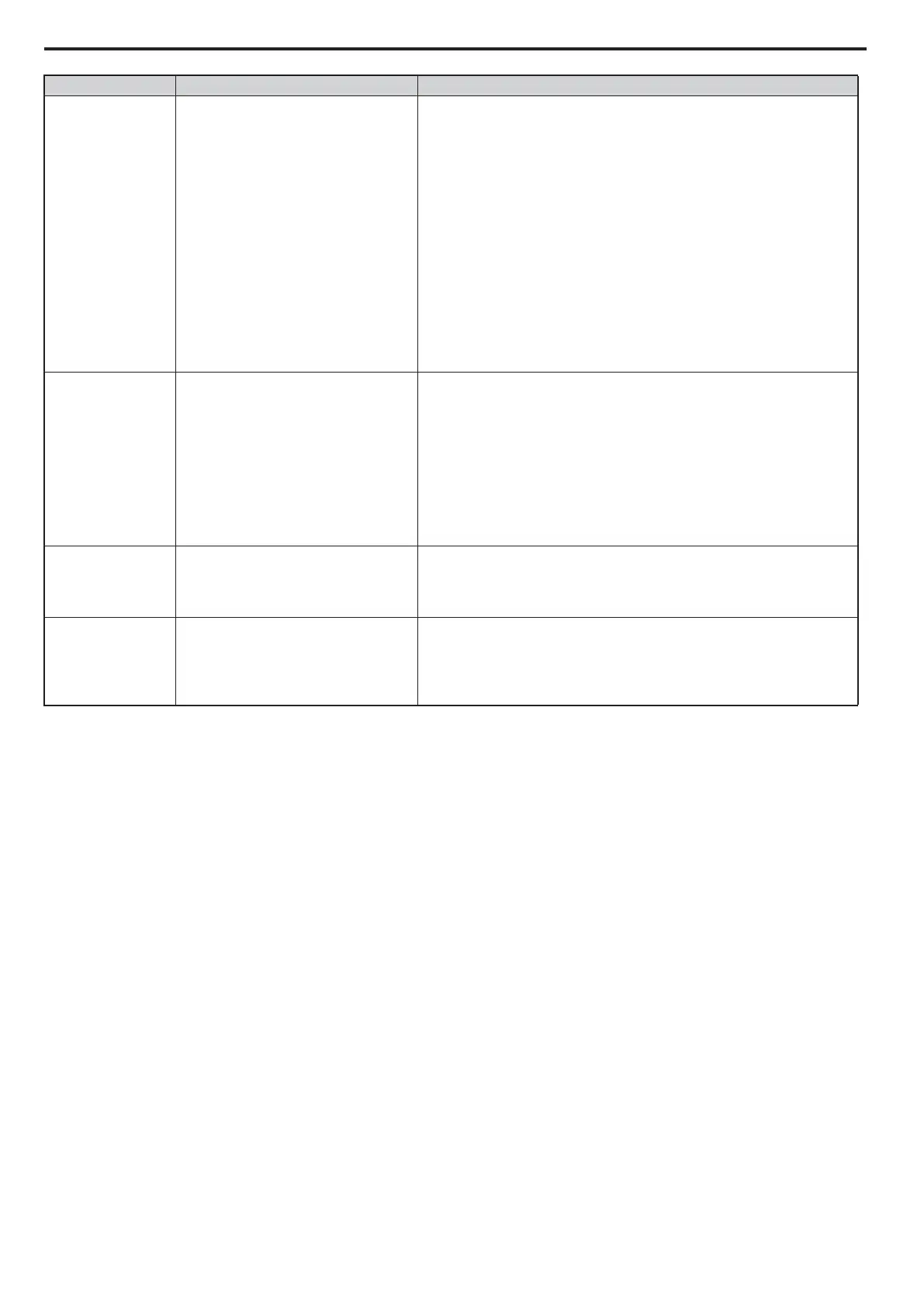

dv7

Polarity Det Flt

Unable to detect the magnetic poles

within the designated time.

Battery voltage is too low.

• Charge the battery.

The output cable is disconnected.

• Check for wiring errors and ensure the output cable is connected properly.

• Correct the wiring.

The motor winding is damaged.

• Check the resistance between the motor lines.

• Replace the motor if the winding is damaged.

The output terminal is loose.

• Apply the tightening torque specified in this manual to fasten the terminals.

Incorrect motor data has been sent.

• Check the parameters in the A5 sub-menu to make sure they match the

information on the motor nameplate.

Non-rotational alignment failure.

• A non-rotational alignment cannot be performed; perform a rotational

alignment instead.

dv8

Pole Detect Flt

An invalid value resulted from Initial

Pole Search.

Note: Reset the fault and try

Initial Pole Search

again.

Brake was released during Initial Pole Search or during power loss.

• Check the brake sequence.

• The brake must remain applied during Initial Pole Search and whenever the

power supply is interrupted.

Initial Pole Search cannot be performed on the monitor being used.

• Use a PG option card that is compatible with both the drive and an absolute

encoder.

Initial Pole Search cannot be performed.

• A non-rotational alignment cannot be performed; perform a rotational

alignment instead.

EF

Up/Down Alarm

Both forward run and reverse run closed

simultaneously for over 0.5 s.

Sequence error.

• Check the forward and reverse command sequence and correct the

problem.

Note: When minor fault EF detected, motor ramps to stop.

EF0

Ext Opt Flt

Opt Card Alarm

An external fault condition is present.

An external fault was received from the PLC.

• Remove the cause of the external fault.

• Remove the external fault from the PLC.

Problem with the PLC program.

• Check the PLC program and correct problems.

Fault Code/Name Description Causes and Solutions

Loading...

Loading...