• Handle circuit boards only by the edges. Do not touch

components or connector pins.

• Ensure that all electrical connections are completely made

and that none are partial or floating. Ground all equipment

to a good, earth ground.

1.3 Before You Begin

1.3.1 Site Preparation

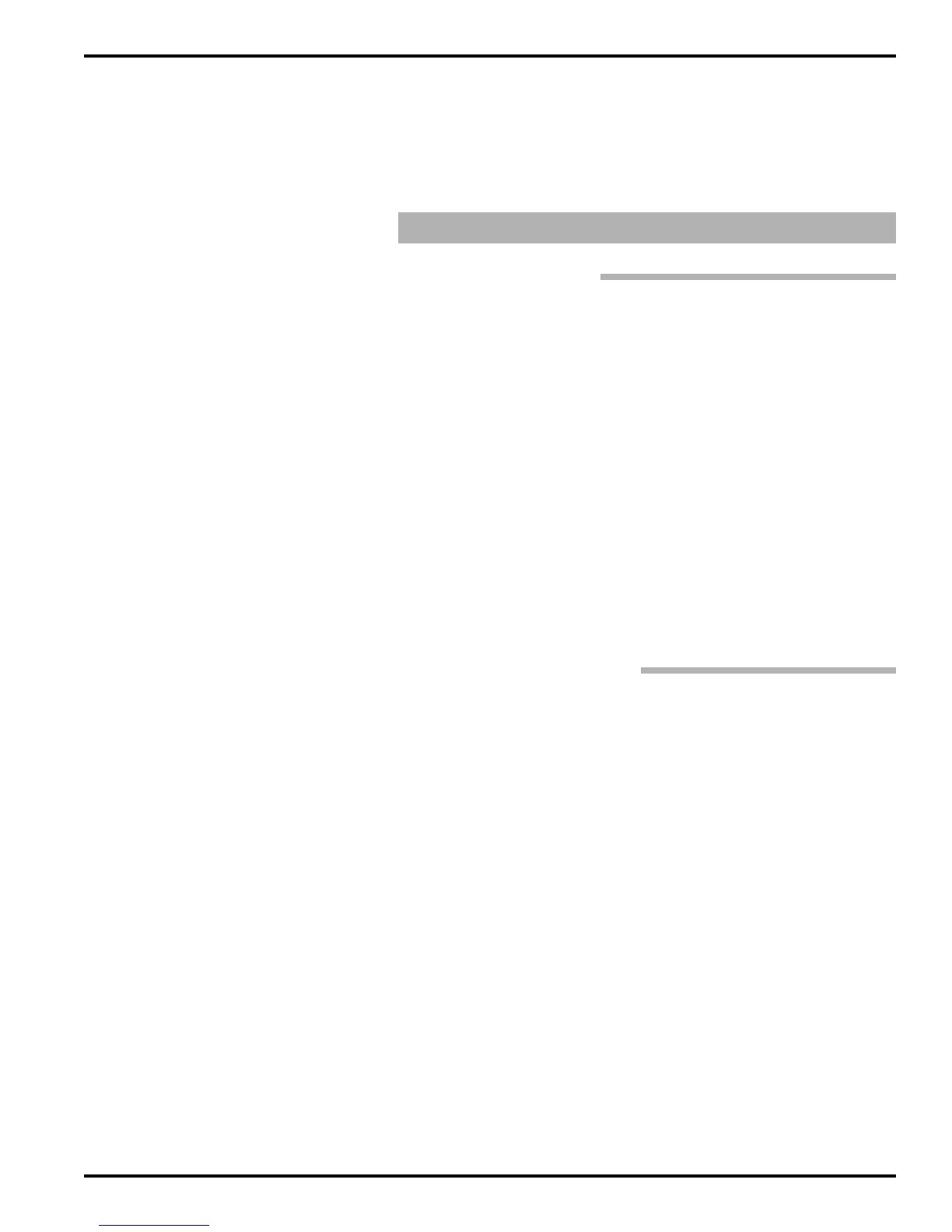

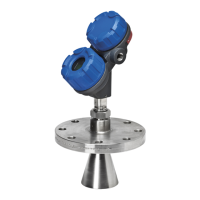

Each Modulevel transmitter is built to match the specific

physical specifications of the required installation. Ensure

that the process connection(s) on the vessel matches the

Modulevel’s process connection(s).

See Mounting, Section 1.4.

Ensure that the wiring between the power supply and

Modulevel transmitter are complete and correct for the

type of installation.

See Specifications, Section 4.8.

When installing the Modulevel transmitter in a general

purpose or hazardous area, local, state and federal regula-

tions and guidelines must be observed.

See Wiring, Sections 2.0 & 3.0.

1.3.2 Equipment and Tools

No special equipment or tools are required to install

the Electronic Modulevel. The following items are

recommended:

• Wrenches, flange gaskets and flange bolting appropriate

for process connection(s)

• Flat-blade screwdriver

• Level

•

1

⁄8" Allen wrench

• Power supply which matches voltage identification on

nameplate

• Multimeter with maximum sensitivity of 100 millivolts for

120 or 240 VAC transmitters

• 250 to 450 ohm resistor for transmitters with HART

communication

2

48-618 ES/EZ Modulevel Displacer Level Transmitter (Top Hat Assembly Design)

Loading...

Loading...