CRANKMECHANISM

Installingtheconnectingrodbearingcap

WARNING

Cracksurfacesaresensitive.The

principleinvolvedcancausechipping

•Exchangetheconnectingrodifthe

cracksurfacesaredamaged

•Protectcracksurfacesagainstdamage

causedbyhardandsharpobjects

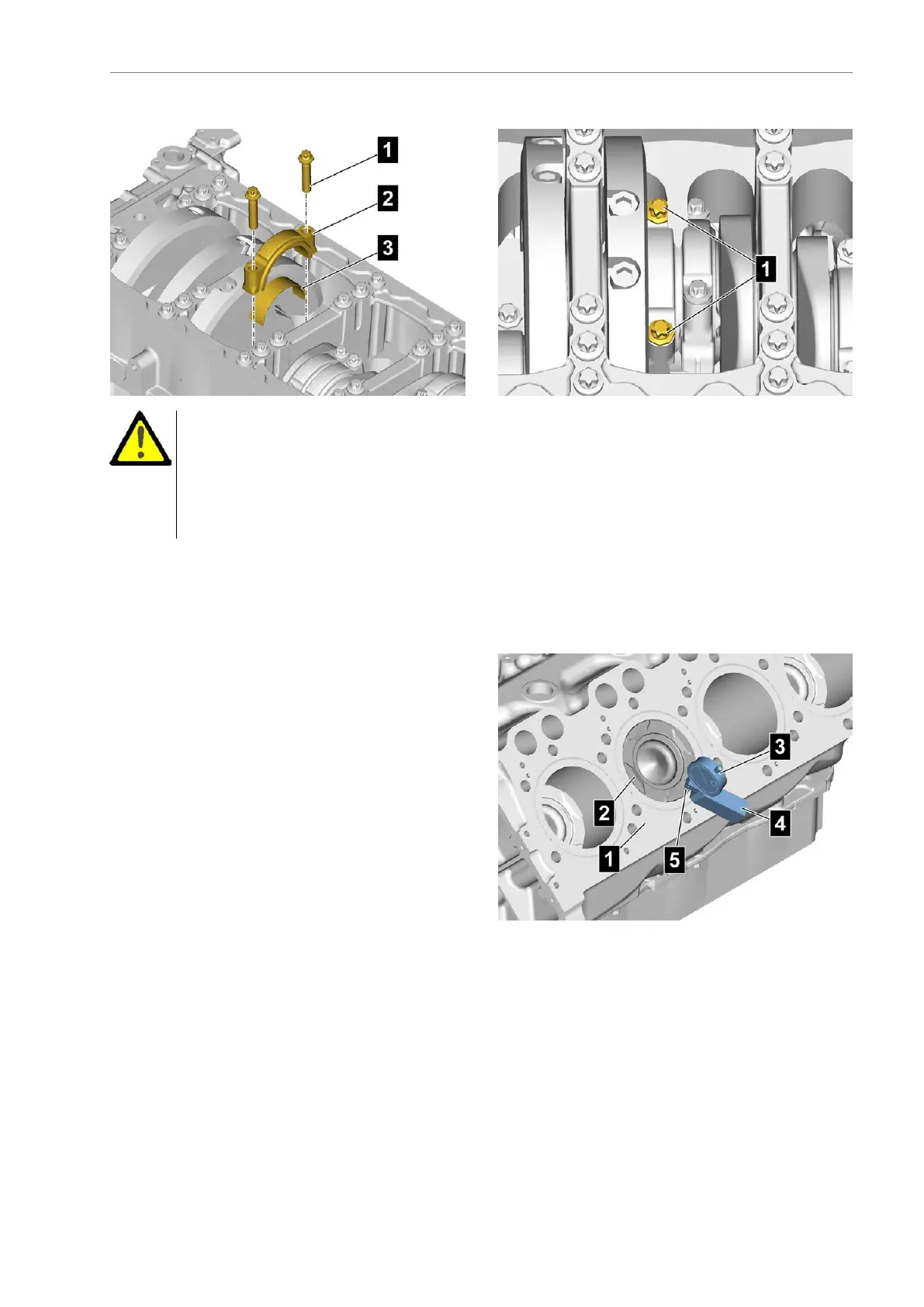

•Inserttheconnectingrodbearingshell(3)into

thecorrespondingconnectingrodbearingcap(2)

accordingtothemarkingandpairing;position

usingtheSettingtool[144]ifnecessary

•Fittheconnectingrodbearingcap(2)with

insertedconnectingrodbearingshell(3)onto

theconnectingrodasmarked,takingcare

nottodamagethecontactsurfacesbetween

theconnectingrodbearingshell(3)andthe

connectingrod

•Screwinthenewconnectingrodbearingbolts(1)

andtightenthembyhand

Tighteningtheconnectingrodbearingshells

•TurnthecrankshafttoBDCtotightenthe

connectingrodbearingbolts(1)

•Checkthealignmentoftheconnectingrod

bearings.Ifnecessary,removetheconnecting

rodbearingshellsandrepositiontheconnecting

rodbearingswithSettingtool[144],thenretthe

connectingrodbearings

•Tightentheconnectingrodbearingbolts(1)to

Initialtorque100Nm

•Tightentheconnectingrodbearingbolts(1)to

Finaltightening90°

Measuringthepistonstandout

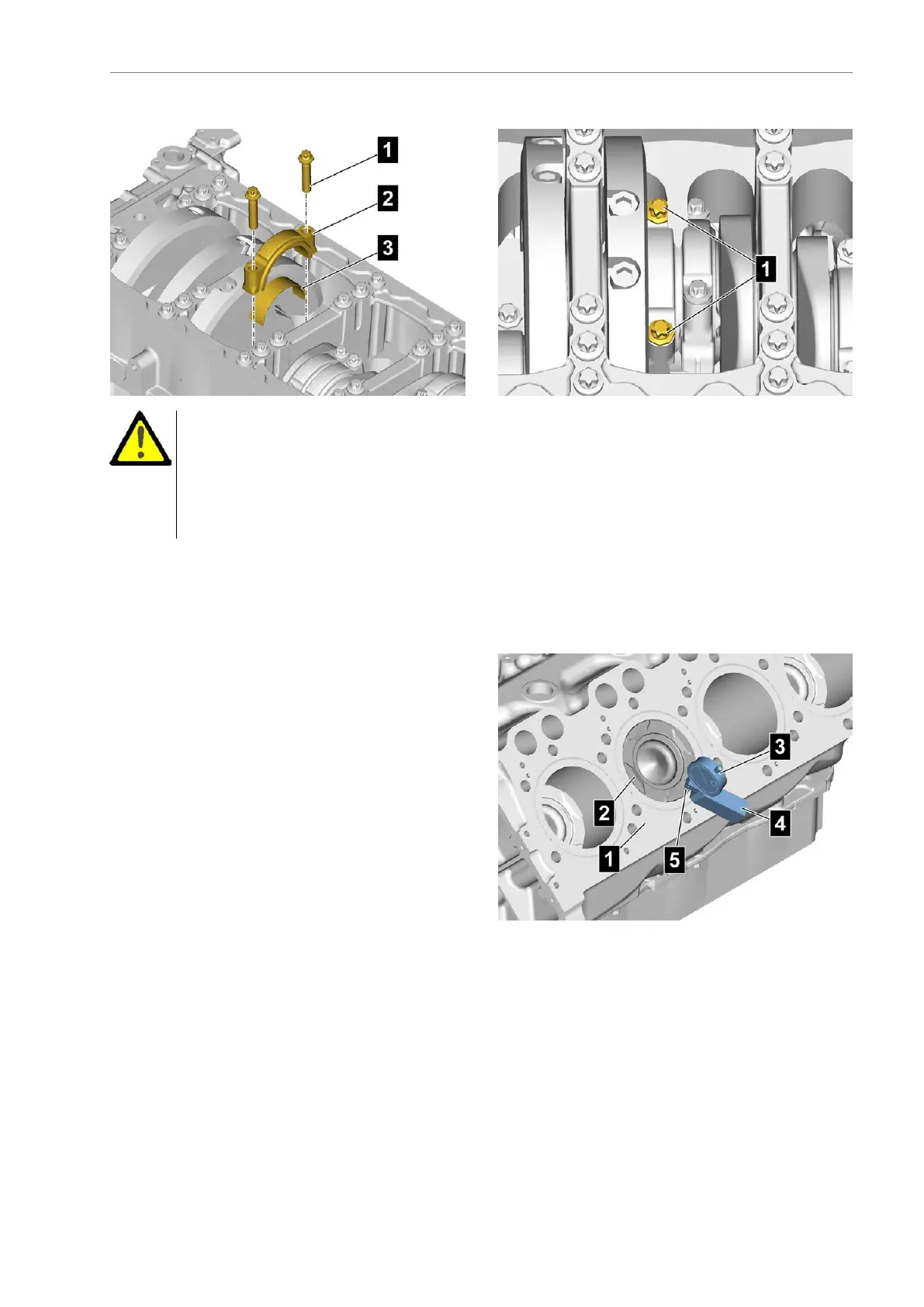

•Setthepiston(2)totopdeadcentre

•PuttheDialgauge[142](3)onthecrankcase(1)

withtheDialgaugeholder[140](4)

•Locatethedialgaugetip(5)onthecrankcase(1)

andzerotheDialgauge[142](3)

•Locatethedialgaugetip(5)onthepiston(2)and

readoffthedifference

Thepermittedpistonstandoutis-0.361to

+0.080mm.

AE63stedition331

Loading...

Loading...